Millwrights specialize in installing, maintaining, and repairing heavy machinery and industrial equipment, often working with precision alignment and assembly tasks in manufacturing plants. Industrial mechanics focus on troubleshooting, maintaining, and repairing a wide range of mechanical equipment, including conveyors, pumps, and hydraulic systems, ensuring continuous production flow. Both roles require strong mechanical skills, but millwrights typically handle more installation and alignment, while industrial mechanics emphasize routine maintenance and repairs.

Table of Comparison

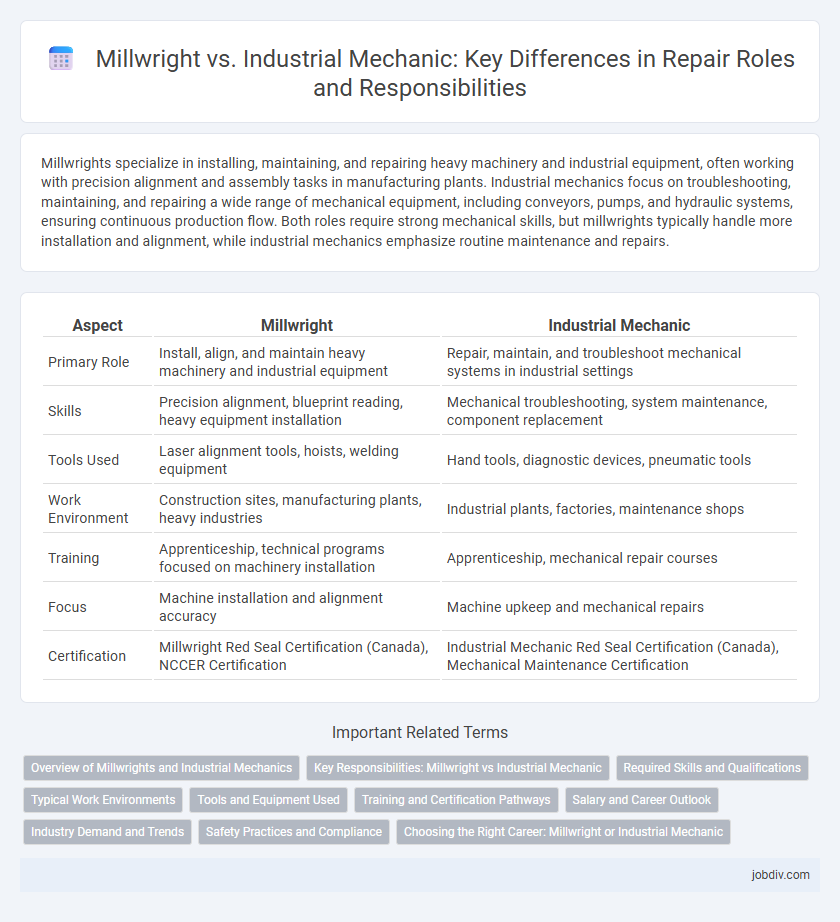

| Aspect | Millwright | Industrial Mechanic |

|---|---|---|

| Primary Role | Install, align, and maintain heavy machinery and industrial equipment | Repair, maintain, and troubleshoot mechanical systems in industrial settings |

| Skills | Precision alignment, blueprint reading, heavy equipment installation | Mechanical troubleshooting, system maintenance, component replacement |

| Tools Used | Laser alignment tools, hoists, welding equipment | Hand tools, diagnostic devices, pneumatic tools |

| Work Environment | Construction sites, manufacturing plants, heavy industries | Industrial plants, factories, maintenance shops |

| Training | Apprenticeship, technical programs focused on machinery installation | Apprenticeship, mechanical repair courses |

| Focus | Machine installation and alignment accuracy | Machine upkeep and mechanical repairs |

| Certification | Millwright Red Seal Certification (Canada), NCCER Certification | Industrial Mechanic Red Seal Certification (Canada), Mechanical Maintenance Certification |

Overview of Millwrights and Industrial Mechanics

Millwrights specialize in installing, maintaining, and repairing heavy machinery and industrial equipment with precision alignment and calibration skills. Industrial mechanics focus on troubleshooting, repairing, and maintaining mechanical systems and equipment in manufacturing plants to ensure optimal performance. Both roles require strong technical expertise but differ in scope, with millwrights often handling the initial setup and installation, while industrial mechanics concentrate on ongoing maintenance and repairs.

Key Responsibilities: Millwright vs Industrial Mechanic

Millwrights primarily focus on installing, aligning, and maintaining heavy machinery in industrial settings, ensuring precise assembly and structural integrity. Industrial mechanics specialize in troubleshooting, repairing, and maintaining mechanical equipment to maximize operational efficiency and minimize downtime. Both roles require expertise in mechanical systems, but millwrights emphasize installation and alignment while industrial mechanics concentrate on repair and maintenance tasks.

Required Skills and Qualifications

Millwrights specialize in installing, maintaining, and repairing heavy machinery using precise alignment and fitting techniques, requiring expertise in blueprint reading, welding, and hydraulics. Industrial mechanics focus on troubleshooting and repairing industrial equipment, demanding strong mechanical aptitude, knowledge of pneumatic and electrical systems, and proficiency in preventive maintenance. Both roles require technical certifications, safety training, and the ability to interpret complex mechanical drawings for efficient repair and maintenance operations.

Typical Work Environments

Millwrights typically work in manufacturing plants, construction sites, and industrial facilities where they install, maintain, and repair heavy machinery and equipment essential for production. Industrial mechanics primarily operate in factories, assembly lines, and maintenance shops, focusing on troubleshooting, repairing, and servicing mechanical systems to ensure continuous operation. Both professions require work in physically demanding environments with exposure to noise, grease, and heavy machinery, emphasizing safety protocols and technical precision.

Tools and Equipment Used

Millwrights use precision tools such as micrometers, lasers, and leveling instruments for installing and aligning heavy machinery, emphasizing accuracy in mechanical system setups. Industrial mechanics utilize diagnostic tools, pneumatic equipment, and welding machines to maintain and repair industrial equipment, prioritizing functionality and quick troubleshooting. Both professions require specialized hand tools like wrenches and hoists, but millwrights focus more on installation alignment tools, while industrial mechanics prioritize repair and maintenance technologies.

Training and Certification Pathways

Millwrights typically undergo apprenticeship programs lasting 3-4 years, combining on-the-job training with technical schooling, often resulting in certification through organizations like the National Center for Construction Education and Research (NCCER). Industrial mechanics generally complete a similar duration of formal training focused on mechanical systems maintenance and troubleshooting, with certification provided by bodies such as the International Maintenance Institute (IMI). Both careers require strong technical skills, but millwrights emphasize installation and alignment of machinery, while industrial mechanics specialize in repair and preventive maintenance.

Salary and Career Outlook

Millwrights typically earn an average salary ranging from $50,000 to $75,000 per year, while industrial mechanics can expect salaries between $55,000 and $80,000 annually, depending on experience and location. The career outlook for both professions is strong, with the U.S. Bureau of Labor Statistics projecting a growth rate of about 5% for millwrights and 4% for industrial mechanics over the next decade. Demand remains high due to ongoing industrial maintenance needs and technological advancements in manufacturing sectors.

Industry Demand and Trends

Industrial Mechanic careers are growing rapidly due to advancements in automation and the need for maintaining complex machinery in manufacturing plants. Millwrights remain in high demand for their specialized skills in installing, aligning, and repairing heavy equipment, especially in sectors like construction and energy. Industry trends indicate a rise in cross-disciplinary expertise, with employers seeking professionals proficient in both mechanical and electronic repair technologies.

Safety Practices and Compliance

Millwrights and Industrial Mechanics both play crucial roles in maintaining industrial equipment, but Millwrights typically engage more with heavy machinery installation and alignment, requiring rigorous safety practices to prevent mechanical hazards. Industrial Mechanics focus on repair and maintenance tasks, emphasizing compliance with lockout/tagout procedures and OSHA standards to ensure workplace safety. Both professions prioritize hazard identification and use personal protective equipment (PPE) to minimize risk during repair operations.

Choosing the Right Career: Millwright or Industrial Mechanic

Choosing between a millwright and an industrial mechanic career hinges on specific skills and work environments; millwrights specialize in installing, maintaining, and repairing heavy machinery and industrial equipment, emphasizing precision alignment and fabrication. Industrial mechanics concentrate on troubleshooting, repairing, and maintaining diverse mechanical systems in manufacturing plants, requiring expertise in hydraulics, pneumatics, and electrical systems. Career choice depends on individual interest in hands-on installation and construction versus continuous mechanical maintenance and system optimization.

Millwright vs Industrial Mechanic Infographic

jobdiv.com

jobdiv.com