Utility Mechanics specialize in repairing and maintaining machinery and equipment to ensure optimal performance and prevent breakdowns. Utility Maintenance Technicians focus on routine inspections, preventive maintenance, and troubleshooting to extend equipment lifespan and minimize downtime. Both roles require technical skills, but mechanics typically handle more complex repairs while technicians emphasize ongoing maintenance tasks.

Table of Comparison

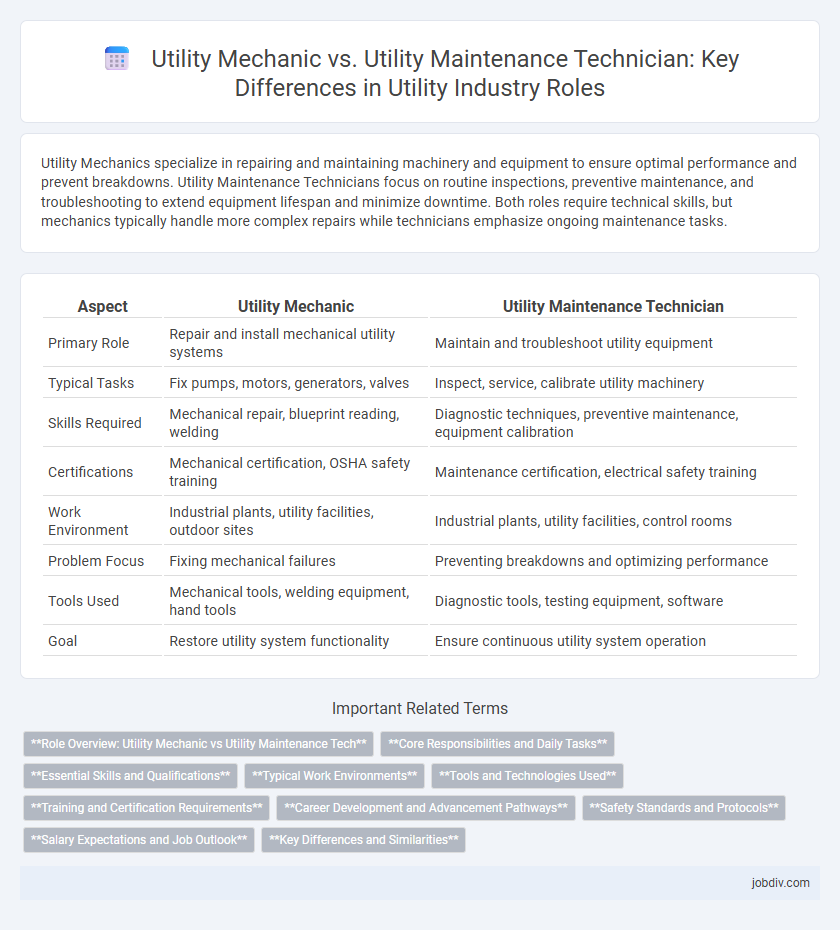

| Aspect | Utility Mechanic | Utility Maintenance Technician |

|---|---|---|

| Primary Role | Repair and install mechanical utility systems | Maintain and troubleshoot utility equipment |

| Typical Tasks | Fix pumps, motors, generators, valves | Inspect, service, calibrate utility machinery |

| Skills Required | Mechanical repair, blueprint reading, welding | Diagnostic techniques, preventive maintenance, equipment calibration |

| Certifications | Mechanical certification, OSHA safety training | Maintenance certification, electrical safety training |

| Work Environment | Industrial plants, utility facilities, outdoor sites | Industrial plants, utility facilities, control rooms |

| Problem Focus | Fixing mechanical failures | Preventing breakdowns and optimizing performance |

| Tools Used | Mechanical tools, welding equipment, hand tools | Diagnostic tools, testing equipment, software |

| Goal | Restore utility system functionality | Ensure continuous utility system operation |

Role Overview: Utility Mechanic vs Utility Maintenance Tech

Utility Mechanics specialize in diagnosing, repairing, and installing mechanical systems such as pumps, compressors, and HVAC units to ensure operational efficiency. Utility Maintenance Technicians focus on routine inspections, preventative maintenance, and troubleshooting of utility equipment to minimize downtime and extend equipment lifespan. Both roles are critical in maintaining facility infrastructure but differ in scope, with mechanics handling complex repairs and technicians emphasizing ongoing upkeep.

Core Responsibilities and Daily Tasks

Utility Mechanics specialize in repairing, installing, and maintaining mechanical equipment such as pumps, compressors, and HVAC systems to ensure efficient utility operations. Utility Maintenance Technicians focus on routine inspections, preventive maintenance, and troubleshooting electrical and mechanical systems to minimize downtime and optimize plant performance. Both roles are essential for sustaining reliable utility services but differ in the scope of technical repairs and maintenance scheduling.

Essential Skills and Qualifications

Utility Mechanics require strong mechanical aptitude, proficiency in interpreting technical schematics, and expertise in operating heavy machinery to install and repair utility systems. Utility Maintenance Technicians must excel in preventative maintenance, troubleshooting electrical and plumbing systems, and adhere to safety regulations to ensure uninterrupted utility services. Both roles demand certifications such as OSHA compliance and experience with system diagnostics to optimize operational efficiency.

Typical Work Environments

Utility Mechanics typically work in industrial settings such as power plants, manufacturing facilities, and water treatment plants, where they repair and maintain heavy machinery and utility systems. Utility Maintenance Technicians often operate in a broader range of environments, including commercial buildings, residential complexes, and municipal infrastructures, performing routine inspections and preventative maintenance on electrical, plumbing, and HVAC systems. Both roles demand adaptability to potentially hazardous environments and adherence to safety protocols.

Tools and Technologies Used

Utility Mechanics primarily work with heavy machinery and power tools such as pneumatic wrenches, hydraulic presses, and welding equipment to install and repair utility systems. Utility Maintenance Technicians utilize diagnostic instruments like multimeters, pipeline inspection cameras, and computerized control systems to monitor and maintain operational efficiency. Both roles require proficiency in industry-specific software for equipment tracking and maintenance scheduling.

Training and Certification Requirements

Utility Mechanics typically require specialized technical training in mechanical systems, often obtained through vocational schools or apprenticeships, along with certifications such as OSHA safety training and industry-specific credentials like NACE Coating Inspector or Welding Certifications. Utility Maintenance Technicians usually need broader training that includes electrical, mechanical, and instrumentation skills, with certifications including EPA Universal Certification, NFPA 70E for electrical safety, and relevant state or federal licenses depending on utility type. Both roles benefit from ongoing professional development to stay current with evolving utility regulations and technological advancements.

Career Development and Advancement Pathways

Utility Mechanics typically advance by gaining specialized skills in equipment repair and system diagnostics, often progressing to lead mechanic or supervisor roles. Utility Maintenance Technicians expand their expertise in preventive maintenance and system optimization, which can lead to positions such as maintenance coordinator or facilities manager. Career development for both roles benefits from certifications like OSHA safety training and technical courses in electrical or mechanical systems.

Safety Standards and Protocols

Utility Mechanics and Utility Maintenance Technicians both prioritize adhering to stringent safety standards and protocols to prevent workplace accidents and ensure reliable utility services. Utility Mechanics focus on safe machinery operation and repair, following lockout/tagout procedures to control hazardous energy during equipment maintenance. Utility Maintenance Technicians emphasize compliance with electrical safety codes, personal protective equipment (PPE) usage, and regular safety audits to mitigate risks in utility infrastructure maintenance.

Salary Expectations and Job Outlook

Utility Mechanics typically earn a median annual salary ranging from $45,000 to $65,000, reflecting their specialized skills in repairing and maintaining utility systems like water, gas, and electrical infrastructure. Utility Maintenance Technicians often have a slightly lower salary range, approximately $40,000 to $60,000, due to their broader role focusing on routine system upkeep and preventative measures. Both positions experience steady job growth driven by aging infrastructure and increased emphasis on utility reliability, with employment projected to grow around 5% over the next decade.

Key Differences and Similarities

Utility Mechanics specialize in repairing and overhauling mechanical systems such as pumps and turbines within utility plants, while Utility Maintenance Technicians focus on routine maintenance, inspections, and troubleshooting across electrical, mechanical, and plumbing systems. Both roles require strong technical skills, knowledge of safety protocols, and the ability to read blueprints and schematics, ensuring the efficient operation of utility infrastructure. Key differences lie in the depth of mechanical expertise for Mechanics versus broader maintenance responsibilities and preventive care executed by Maintenance Technicians.

Utility Mechanic vs Utility Maintenance Tech Infographic

jobdiv.com

jobdiv.com