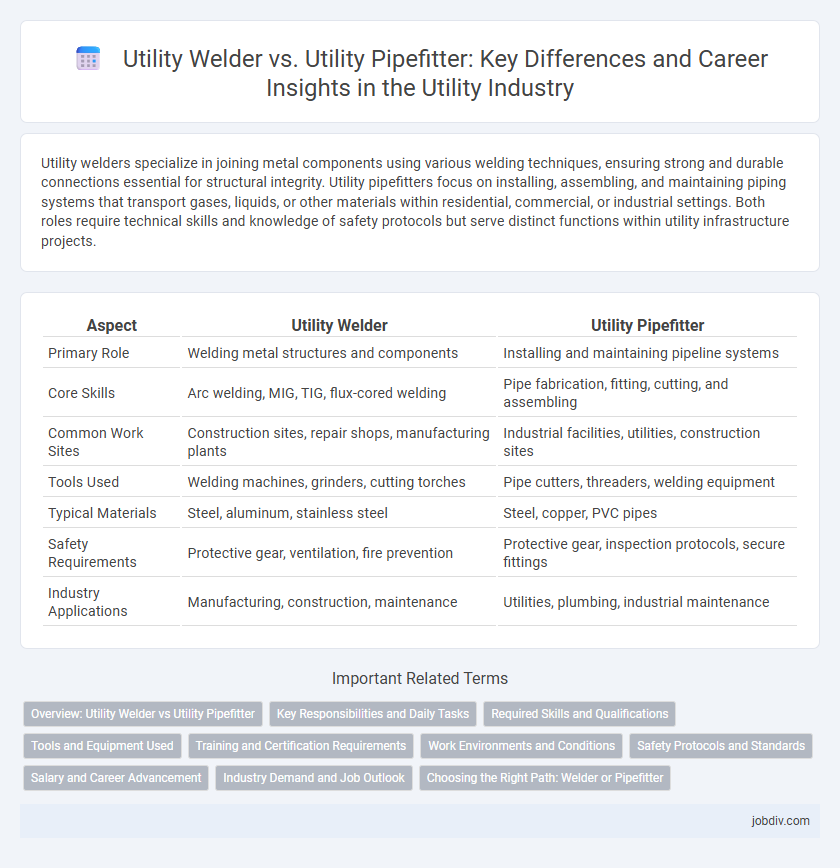

Utility welders specialize in joining metal components using various welding techniques, ensuring strong and durable connections essential for structural integrity. Utility pipefitters focus on installing, assembling, and maintaining piping systems that transport gases, liquids, or other materials within residential, commercial, or industrial settings. Both roles require technical skills and knowledge of safety protocols but serve distinct functions within utility infrastructure projects.

Table of Comparison

| Aspect | Utility Welder | Utility Pipefitter |

|---|---|---|

| Primary Role | Welding metal structures and components | Installing and maintaining pipeline systems |

| Core Skills | Arc welding, MIG, TIG, flux-cored welding | Pipe fabrication, fitting, cutting, and assembling |

| Common Work Sites | Construction sites, repair shops, manufacturing plants | Industrial facilities, utilities, construction sites |

| Tools Used | Welding machines, grinders, cutting torches | Pipe cutters, threaders, welding equipment |

| Typical Materials | Steel, aluminum, stainless steel | Steel, copper, PVC pipes |

| Safety Requirements | Protective gear, ventilation, fire prevention | Protective gear, inspection protocols, secure fittings |

| Industry Applications | Manufacturing, construction, maintenance | Utilities, plumbing, industrial maintenance |

Overview: Utility Welder vs Utility Pipefitter

Utility welders specialize in joining metal components in pipelines, often working on gas, water, or steam distribution systems to ensure secure and leak-proof connections. Utility pipefitters focus on installing, assembling, and maintaining piping systems that transport various utilities, requiring skill in reading blueprints and handling specialized tools. Both roles are crucial in infrastructure maintenance but differ in their core tasks, with welders concentrating on metal fusion and pipefitters emphasizing system assembly and repair.

Key Responsibilities and Daily Tasks

Utility welders specialize in fusing metal components for pipelines, tanks, and infrastructure, ensuring leak-proof and durable connections through techniques like arc welding, MIG, and TIG welding. Utility pipefitters focus on assembling, installing, and maintaining piping systems that transport water, gas, or other utilities, reading blueprints and schematics to properly align and secure pipes using hand and power tools. Both roles require adherence to safety standards and routine inspection of equipment to maintain operational efficiency and prevent system failures.

Required Skills and Qualifications

Utility welders must possess advanced welding skills including MIG, TIG, and stick welding, along with certification from recognized bodies such as the American Welding Society (AWS). Utility pipefitters require strong knowledge of pipe layout, fitting techniques, and blueprint reading, often supported by apprenticeships and certifications like the NCCER Pipefitter program. Both roles demand physical stamina, safety training, and the ability to work in various outdoor and industrial environments.

Tools and Equipment Used

Utility welders primarily use welding machines, welding electrodes, grinders, and cutting torches to join metals in utility infrastructure projects. Utility pipefitters rely on pipe wrenches, threading machines, pipe cutters, and measuring instruments to assemble, install, and maintain piping systems. Both trades require safety gear such as gloves, helmets, and protective eyewear to ensure secure and efficient operations.

Training and Certification Requirements

Utility welders require specialized training in welding techniques, safety protocols, and metallurgy, often obtaining certifications such as the Certified Welder (CW) credential from the American Welding Society (AWS). Utility pipefitters focus on pipe installation, maintenance, and repair, necessitating training in blueprint reading, pipe threading, and OSHA safety standards, commonly earning certifications like the Certified Pipefitter (CP) or NCCER Pipefitting credentials. Both roles demand rigorous hands-on apprenticeship programs and continuous education to stay compliant with evolving industry regulations and technological advancements.

Work Environments and Conditions

Utility welders typically work in diverse environments including construction sites, industrial plants, and outdoor settings where they join metal components under varying weather conditions. Utility pipefitters operate primarily in confined spaces such as basements, underground tunnels, and inside industrial facilities, often dealing with high-pressure piping systems. Both roles demand physical endurance and adherence to safety protocols, but pipefitters face greater exposure to hazardous materials and tight, cramped spaces.

Safety Protocols and Standards

Utility welders and utility pipefitters adhere to strict safety protocols and standards to prevent workplace hazards such as electrical shocks, burns, and exposure to toxic fumes. Utility welders must follow OSHA regulations for welding safety, including proper use of personal protective equipment (PPE) like helmets, gloves, and flame-resistant clothing, while utility pipefitters prioritize adherence to confined space entry procedures and pipe handling protocols to avoid injuries. Both professionals undergo rigorous training in hazard communication, fire prevention, and emergency response to ensure compliance with industry safety standards.

Salary and Career Advancement

Utility welders typically earn an average salary ranging from $45,000 to $65,000 annually, with opportunities to increase earnings through certifications and specialized welding techniques. Utility pipefitters often command higher salaries, averaging between $50,000 and $75,000, driven by their expertise in installing and maintaining complex piping systems. Career advancement for pipefitters usually involves supervisory roles or project management, while welders can progress by mastering advanced welding processes or transitioning into inspection and quality control positions.

Industry Demand and Job Outlook

The utility welder and utility pipefitter roles both experience strong industry demand due to ongoing infrastructure projects and maintenance in water, gas, and energy sectors. Utility welders are in high demand for precision welding on pipelines and structural components, while utility pipefitters are crucial for installing and repairing complex piping systems in industrial and municipal utilities. Job outlook for both trades remains robust, driven by aging infrastructure replacement and the expansion of renewable energy utilities.

Choosing the Right Path: Welder or Pipefitter

Choosing between a utility welder and a utility pipefitter depends on the specific skills and project requirements within the utility sector. Utility welders specialize in joining metal components with precision, essential for fabricating and repairing infrastructure such as pipelines and equipment. Utility pipefitters focus on installing and maintaining piping systems, emphasizing system integrity and flow management in utility services.

Utility Welder vs Utility Pipefitter Infographic

jobdiv.com

jobdiv.com