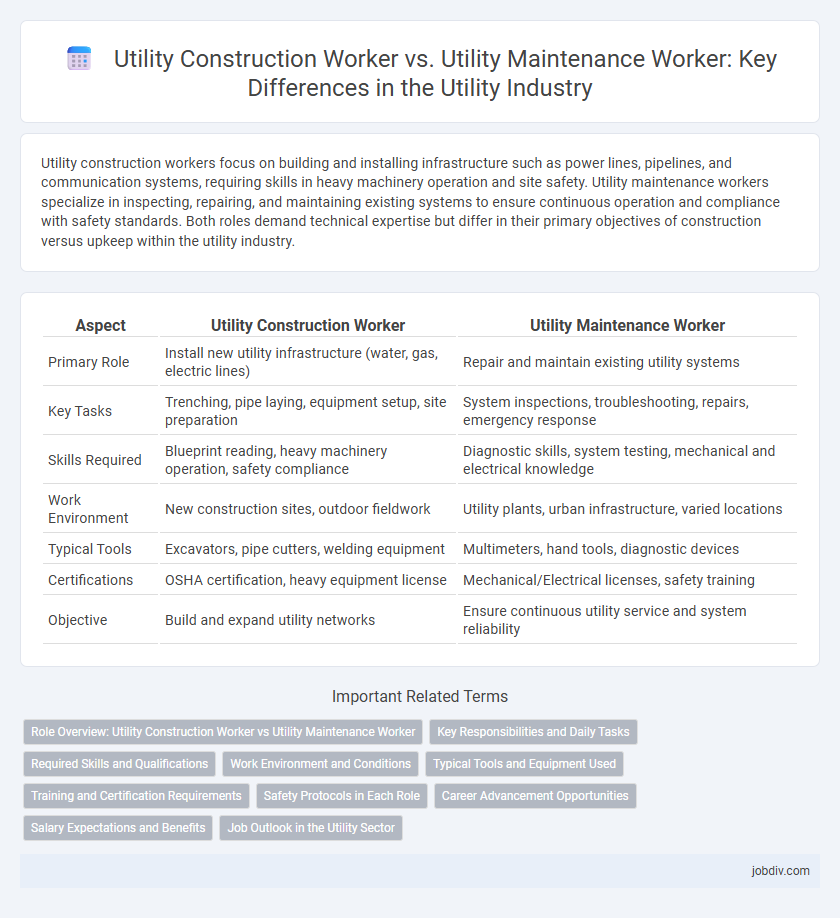

Utility construction workers focus on building and installing infrastructure such as power lines, pipelines, and communication systems, requiring skills in heavy machinery operation and site safety. Utility maintenance workers specialize in inspecting, repairing, and maintaining existing systems to ensure continuous operation and compliance with safety standards. Both roles demand technical expertise but differ in their primary objectives of construction versus upkeep within the utility industry.

Table of Comparison

| Aspect | Utility Construction Worker | Utility Maintenance Worker |

|---|---|---|

| Primary Role | Install new utility infrastructure (water, gas, electric lines) | Repair and maintain existing utility systems |

| Key Tasks | Trenching, pipe laying, equipment setup, site preparation | System inspections, troubleshooting, repairs, emergency response |

| Skills Required | Blueprint reading, heavy machinery operation, safety compliance | Diagnostic skills, system testing, mechanical and electrical knowledge |

| Work Environment | New construction sites, outdoor fieldwork | Utility plants, urban infrastructure, varied locations |

| Typical Tools | Excavators, pipe cutters, welding equipment | Multimeters, hand tools, diagnostic devices |

| Certifications | OSHA certification, heavy equipment license | Mechanical/Electrical licenses, safety training |

| Objective | Build and expand utility networks | Ensure continuous utility service and system reliability |

Role Overview: Utility Construction Worker vs Utility Maintenance Worker

Utility Construction Workers specialize in installing and building essential infrastructure such as water, gas, and electrical lines, often working on new projects or expansions. Utility Maintenance Workers focus on inspecting, repairing, and maintaining existing utility systems to ensure continuous service and prevent outages. Both roles require knowledge of safety protocols and utility regulations but differ in their focus on construction versus ongoing system upkeep.

Key Responsibilities and Daily Tasks

Utility Construction Workers primarily focus on installing and building infrastructure such as water, gas, and electrical lines, ensuring compliance with building codes and safety regulations. Utility Maintenance Workers specialize in inspecting, repairing, and maintaining existing utility systems to prevent outages and ensure continuous service. Daily tasks for Construction Workers include trenching, pipe fitting, and equipment operation, while Maintenance Workers routinely perform system diagnostics, emergency repairs, and routine inspections.

Required Skills and Qualifications

Utility Construction Workers require skills in heavy equipment operation, knowledge of construction blueprints, and physical stamina to handle pipeline installations and infrastructure projects. Utility Maintenance Workers must possess expertise in troubleshooting, repairing electrical and mechanical systems, and performing routine inspections to ensure the continuous operation of utility services. Both roles demand safety certifications, such as OSHA training, and the ability to work in various weather conditions.

Work Environment and Conditions

Utility Construction Workers operate primarily in outdoor and often hazardous environments, including trenches, construction sites, and areas with heavy machinery. Utility Maintenance Workers typically work in both outdoor and indoor settings, focusing on repairing and maintaining existing infrastructure under varying weather conditions. Both roles require adherence to safety protocols, but construction workers face more physically demanding tasks and exposure to construction-related risks.

Typical Tools and Equipment Used

Utility Construction Workers primarily use heavy equipment such as excavators, backhoes, and trenchers for digging and laying pipes or cables. Utility Maintenance Workers commonly employ diagnostic tools including cable locators, voltage testers, and handheld meters to inspect, repair, and maintain existing utility infrastructure. Both roles rely on safety gear like hard hats, gloves, and high-visibility vests to ensure a secure working environment.

Training and Certification Requirements

Utility Construction Workers typically require specialized training in heavy equipment operation, safety protocols, and construction techniques, often supported by OSHA certifications and apprenticeships. Utility Maintenance Workers need certifications related to electrical systems, plumbing, or mechanical maintenance, with an emphasis on ongoing safety training and technical skill development. Both roles demand adherence to industry standards, but construction workers often undergo more rigorous initial training, while maintenance workers focus on continuous certification updates.

Safety Protocols in Each Role

Utility construction workers follow rigorous safety protocols such as wearing personal protective equipment (PPE), conducting site hazard assessments, and adhering to strict excavation and trenching regulations to prevent accidents during installation and repair activities. Utility maintenance workers prioritize safety by implementing lockout/tagout procedures, regularly inspecting and maintaining equipment, and monitoring for electrical hazards to ensure ongoing operational safety. Both roles require comprehensive safety training and compliance with Occupational Safety and Health Administration (OSHA) standards to minimize risks in high-risk utility environments.

Career Advancement Opportunities

Utility Construction Workers often gain hands-on experience with infrastructure installation, providing a strong foundation for advancement into supervisory roles or specialized technical positions. Utility Maintenance Workers develop expertise in system troubleshooting and repair, which can lead to career growth in maintenance management or engineering fields. Both career paths offer opportunities for certification and skill development that enhance long-term professional advancement within the utility industry.

Salary Expectations and Benefits

Utility Construction Workers typically earn between $40,000 and $65,000 annually, with salary varying based on location, experience, and project complexity. Utility Maintenance Workers often have a salary range of $45,000 to $70,000, reflecting their specialized skills in equipment upkeep and emergency repairs. Benefits for both roles generally include health insurance, retirement plans, paid leave, and opportunities for overtime pay, with maintenance workers sometimes receiving higher compensation due to the critical nature of their tasks.

Job Outlook in the Utility Sector

The job outlook for Utility Construction Workers is expected to grow by 8% through 2030 due to increasing infrastructure upgrades and renewable energy projects. Utility Maintenance Workers face a steady demand with a projected growth rate of 5%, driven by ongoing system repairs and modernization efforts. Both roles are vital for sustaining and expanding utility networks, but Construction Workers show faster growth linked to new installations.

Utility Construction Worker vs Utility Maintenance Worker Infographic

jobdiv.com

jobdiv.com