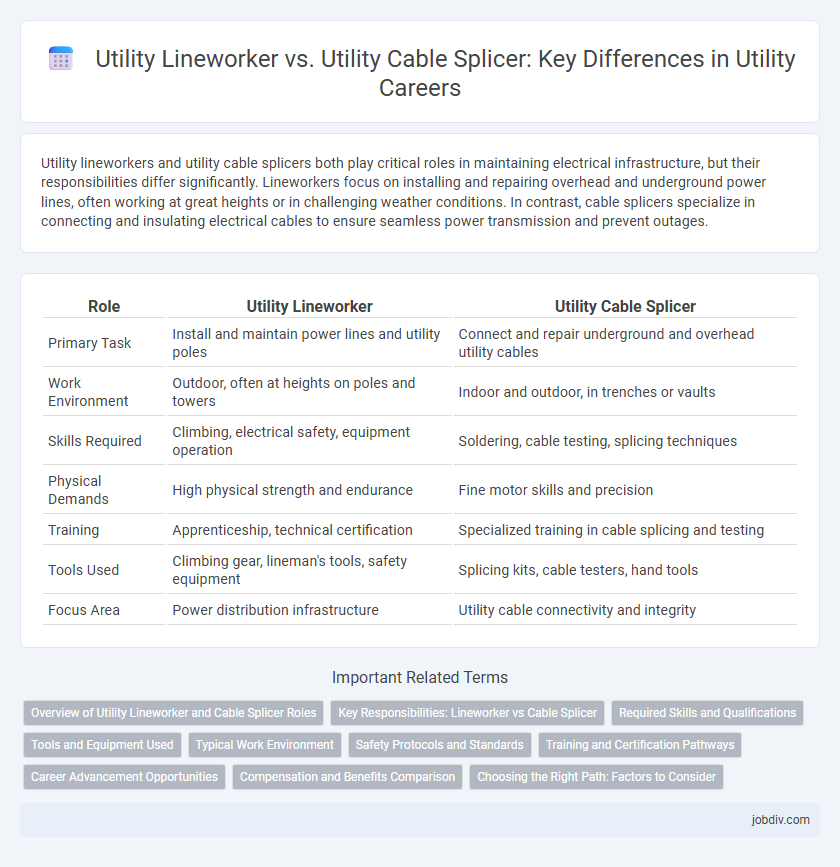

Utility lineworkers and utility cable splicers both play critical roles in maintaining electrical infrastructure, but their responsibilities differ significantly. Lineworkers focus on installing and repairing overhead and underground power lines, often working at great heights or in challenging weather conditions. In contrast, cable splicers specialize in connecting and insulating electrical cables to ensure seamless power transmission and prevent outages.

Table of Comparison

| Role | Utility Lineworker | Utility Cable Splicer |

|---|---|---|

| Primary Task | Install and maintain power lines and utility poles | Connect and repair underground and overhead utility cables |

| Work Environment | Outdoor, often at heights on poles and towers | Indoor and outdoor, in trenches or vaults |

| Skills Required | Climbing, electrical safety, equipment operation | Soldering, cable testing, splicing techniques |

| Physical Demands | High physical strength and endurance | Fine motor skills and precision |

| Training | Apprenticeship, technical certification | Specialized training in cable splicing and testing |

| Tools Used | Climbing gear, lineman's tools, safety equipment | Splicing kits, cable testers, hand tools |

| Focus Area | Power distribution infrastructure | Utility cable connectivity and integrity |

Overview of Utility Lineworker and Cable Splicer Roles

Utility Lineworkers are responsible for installing, maintaining, and repairing overhead and underground power lines, ensuring reliable electricity distribution. Utility Cable Splicers specialize in joining and repairing electrical cables, focusing on underground cable networks to maintain continuous power flow. Both roles require technical expertise, safety compliance, and the ability to work in challenging environments to support utility infrastructure integrity.

Key Responsibilities: Lineworker vs Cable Splicer

Utility lineworkers primarily install, maintain, and repair overhead and underground electrical power lines, ensuring reliable electricity distribution and system safety. Utility cable splicers specialize in joining and repairing electrical cables, using precise techniques to restore connectivity within complex underground or aerial fiber optic and power cable systems. Both roles require adherence to strict safety protocols, with lineworkers focusing on infrastructure installation and maintenance, while cable splicers concentrate on detailed cable jointing and troubleshooting.

Required Skills and Qualifications

Utility Lineworkers require strong physical endurance, expertise in high-voltage electrical systems, and the ability to work at heights to install and maintain power lines safely. Utility Cable Splicers need precise hand-eye coordination, in-depth knowledge of cable types and splicing techniques, and proficiency with specialized tools to join and repair underground and overhead cables effectively. Both roles demand adherence to strict safety protocols, electrical knowledge, and relevant certifications such as OSHA training and journeyman lineman qualifications.

Tools and Equipment Used

Utility Lineworkers typically use equipment such as insulated climbing gear, hot sticks, voltage detectors, and hydraulic bucket trucks to maintain and repair power lines safely. Utility Cable Splicers rely on precision tools like fusion splicers, cable strippers, cleavers, and testing devices to join and troubleshoot fiber optic or electrical cables accurately. Both roles require specialized protective gear, but their tools reflect the distinct technical tasks essential to power line maintenance and cable connectivity.

Typical Work Environment

Utility lineworkers typically work outdoors in various weather conditions, often at heights on poles or towers, handling electrical power distribution and maintenance. Utility cable splicers primarily operate in more controlled environments, such as underground vaults or indoor substations, focusing on connecting and repairing cable systems. Both roles require adherence to strict safety protocols due to exposure to high-voltage electricity and potentially hazardous settings.

Safety Protocols and Standards

Utility lineworkers and utility cable splicers adhere to stringent safety protocols and industry standards to mitigate risks associated with high-voltage electrical systems. Lineworkers follow rigorous lockout/tagout procedures, wear insulated personal protective equipment (PPE), and maintain minimum approach distances to prevent arc flashes and electrocution during overhead line maintenance. Cable splicers comply with OSHA regulations and ANSI standards, utilizing specialized gloves, grounding techniques, and confined space entry protocols to ensure safe handling of underground cables and avoid electric shock or trench collapse.

Training and Certification Pathways

Utility lineworkers typically undergo rigorous training through accredited apprenticeship programs lasting three to four years, combining on-the-job experience with classroom instruction focused on electrical systems and safety protocols. Utility cable splicers require specialized certification in cable splicing techniques, including fiber optic and high-voltage splicing, usually obtained through vocational schools or industry-recognized programs such as those offered by the National Joint Apprenticeship and Training Committee (NJATC). Both career paths demand adherence to Occupational Safety and Health Administration (OSHA) standards, with lineworkers emphasizing physical climbing and pole work certifications, while cable splicers concentrate on advanced technical competencies in cable jointing and troubleshooting.

Career Advancement Opportunities

Utility lineworkers often have faster entry-level access and diverse fieldwork experience, which can lead to supervisory roles or specialized certifications in power distribution. Utility cable splicers acquire highly technical skills in fiber optic and electrical cable repair, positioning them for advanced technical specialist roles or project management in telecommunications. Both careers offer distinct paths, with lineworkers typically advancing through leadership in field operations, while splicers progress through expertise in complex cable systems and infrastructure upgrades.

Compensation and Benefits Comparison

Utility Lineworkers earn an average annual salary ranging from $60,000 to $80,000, with benefits including health insurance, retirement plans, and overtime pay for emergency work. Utility Cable Splicers typically command a higher wage, averaging $70,000 to $90,000 annually, reflecting their specialized skills in splicing and maintaining high-voltage lines. Both roles receive similar comprehensive benefits, but splicers often have access to better hazard pay and skill-based bonuses.

Choosing the Right Path: Factors to Consider

Utility lineworkers specialize in the installation and maintenance of overhead and underground power lines, ensuring reliable electricity delivery and public safety. Utility cable splicers focus on connecting and repairing cables, requiring precision and expertise in handling complex wiring systems. When choosing the right path, consider factors like physical demands, technical skills, work environment, and career advancement opportunities unique to each role.

Utility Lineworker vs Utility Cable Splicer Infographic

jobdiv.com

jobdiv.com