Utility Maintenance Workers perform essential tasks such as routine repairs, equipment inspections, and basic troubleshooting to ensure utility systems operate efficiently. Utility Maintenance Technicians possess advanced skills and specialized training, allowing them to handle complex electrical, mechanical, and instrumentation maintenance, often involving diagnostics and system upgrades. Both roles are critical, but technicians typically take on more technical responsibilities and problem-solving duties in utility maintenance operations.

Table of Comparison

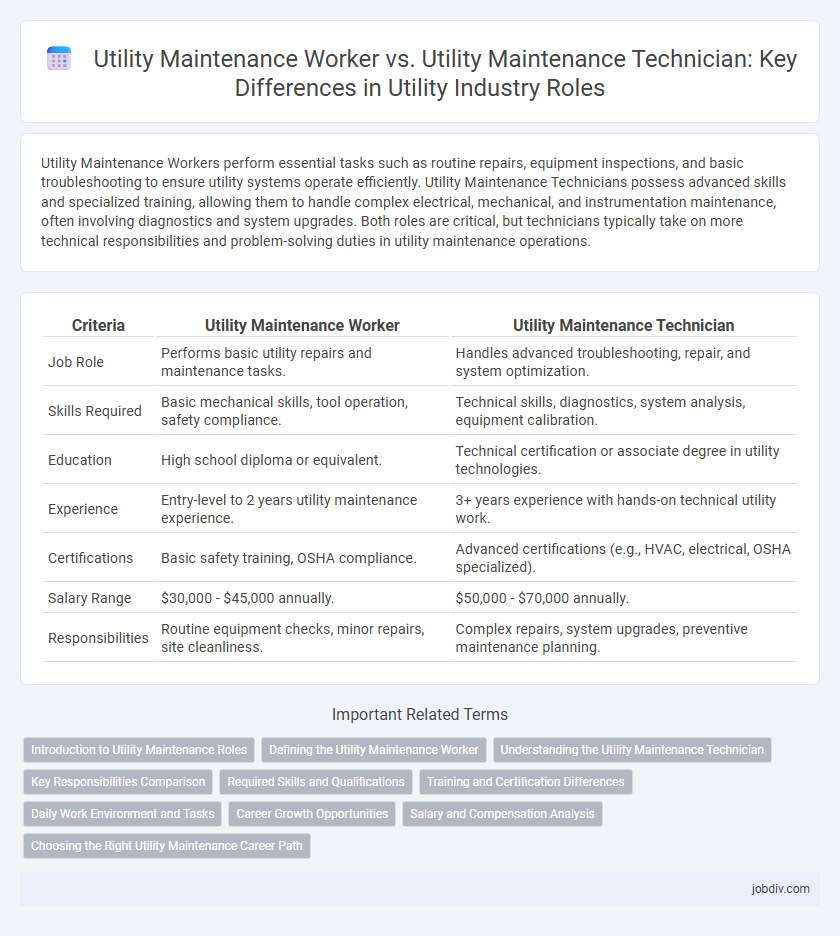

| Criteria | Utility Maintenance Worker | Utility Maintenance Technician |

|---|---|---|

| Job Role | Performs basic utility repairs and maintenance tasks. | Handles advanced troubleshooting, repair, and system optimization. |

| Skills Required | Basic mechanical skills, tool operation, safety compliance. | Technical skills, diagnostics, system analysis, equipment calibration. |

| Education | High school diploma or equivalent. | Technical certification or associate degree in utility technologies. |

| Experience | Entry-level to 2 years utility maintenance experience. | 3+ years experience with hands-on technical utility work. |

| Certifications | Basic safety training, OSHA compliance. | Advanced certifications (e.g., HVAC, electrical, OSHA specialized). |

| Salary Range | $30,000 - $45,000 annually. | $50,000 - $70,000 annually. |

| Responsibilities | Routine equipment checks, minor repairs, site cleanliness. | Complex repairs, system upgrades, preventive maintenance planning. |

Introduction to Utility Maintenance Roles

Utility Maintenance Workers perform essential hands-on tasks such as repairing and maintaining utility systems including water, gas, and electricity, ensuring continuous service and safety. Utility Maintenance Technicians possess advanced technical skills and typically handle complex diagnostics, equipment calibration, and system optimization using specialized tools. Both roles are critical for the reliable operation and infrastructure longevity of utility services in residential, commercial, and industrial settings.

Defining the Utility Maintenance Worker

A Utility Maintenance Worker performs essential tasks such as inspecting, repairing, and maintaining utility infrastructure including water, gas, and electrical systems to ensure continuous service and safety. They handle manual labor involving the installation and upkeep of pipes, cables, and meters while monitoring utility equipment for faults or malfunctions. This role prioritizes hands-on maintenance operations and routine system checks to prevent service disruptions.

Understanding the Utility Maintenance Technician

Utility Maintenance Technicians possess advanced technical skills and specialized knowledge in diagnosing, repairing, and maintaining complex utility systems such as electrical grids, water treatment facilities, and HVAC units. Unlike Utility Maintenance Workers who typically handle routine manual tasks, Technicians utilize diagnostic tools and equipment to ensure system efficiency, safety, and compliance with industry standards. Their expertise in troubleshooting and preventive maintenance reduces downtime and extends the lifespan of critical infrastructure.

Key Responsibilities Comparison

Utility Maintenance Workers primarily perform routine inspections, equipment cleaning, and basic repairs to ensure the operational efficiency of utility systems. Utility Maintenance Technicians handle more complex diagnostics, preventive maintenance, and advanced machinery troubleshooting to maintain and enhance infrastructure reliability. Both roles are essential for minimizing service interruptions and ensuring compliance with safety and regulatory standards.

Required Skills and Qualifications

Utility Maintenance Workers require basic knowledge of electrical, plumbing, and mechanical systems, often supported by a high school diploma or GED, and hands-on experience in utility repairs and maintenance. Utility Maintenance Technicians need advanced technical skills, including proficiency in diagnostic tools, system troubleshooting, and safety protocols, typically holding certifications or an associate degree in utility technology or a related field. Both roles demand physical stamina, problem-solving abilities, and compliance with regulatory standards, but Technicians usually handle more complex systems and require higher-level qualifications.

Training and Certification Differences

Utility Maintenance Workers typically require basic vocational training and on-the-job experience, emphasizing general maintenance skills and safety protocols. Utility Maintenance Technicians often complete advanced technical training programs and possess certifications such as NCCER or EPA Universal Technician, enabling them to perform specialized diagnostic and repair tasks. The technician role demands a higher level of expertise, demonstrated by formal certification and continuous professional development.

Daily Work Environment and Tasks

Utility Maintenance Workers operate primarily in outdoor environments, performing manual labor such as repairing water lines, clearing debris, and maintaining utility infrastructures. Utility Maintenance Technicians work in both indoor and outdoor settings, utilizing technical skills to troubleshoot, inspect, and maintain electrical, plumbing, or HVAC systems with specialized tools and diagnostic equipment. Both roles require adherence to safety protocols, but technicians often engage in more complex problem-solving tasks involving technical documentation and system analysis.

Career Growth Opportunities

Utility Maintenance Technicians typically have broader technical knowledge and specialized training, enabling them to handle complex diagnostic and repair tasks in utility systems. Utility Maintenance Workers often perform routine maintenance and support tasks but may face limited advancement without acquiring additional certifications or technical skills. Career growth opportunities for Technicians include roles like system analysts or supervisors, while Workers progress by gaining experience or further education to bridge the skills gap.

Salary and Compensation Analysis

Utility Maintenance Technicians generally earn higher salaries compared to Utility Maintenance Workers due to advanced technical skills and certifications required for their roles. According to industry salary data, technicians receive median annual wages ranging from $45,000 to $65,000, while workers typically earn between $30,000 and $45,000. Benefits packages for technicians often include enhanced overtime pay, skill-based bonuses, and comprehensive health insurance plans, reflecting their specialized expertise.

Choosing the Right Utility Maintenance Career Path

Utility Maintenance Workers perform routine inspections, basic repairs, and preventive maintenance on utility infrastructure, making them suitable for entry-level positions. Utility Maintenance Technicians possess advanced technical skills, often handling complex diagnostics, system upgrades, and specialized equipment operation, aligning with more specialized or senior roles. Choosing the right utility maintenance career path depends on one's skill level, certification, and interest in progressing toward technical expertise versus foundational maintenance tasks.

Utility Maintenance Worker vs Utility Maintenance Technician Infographic

jobdiv.com

jobdiv.com