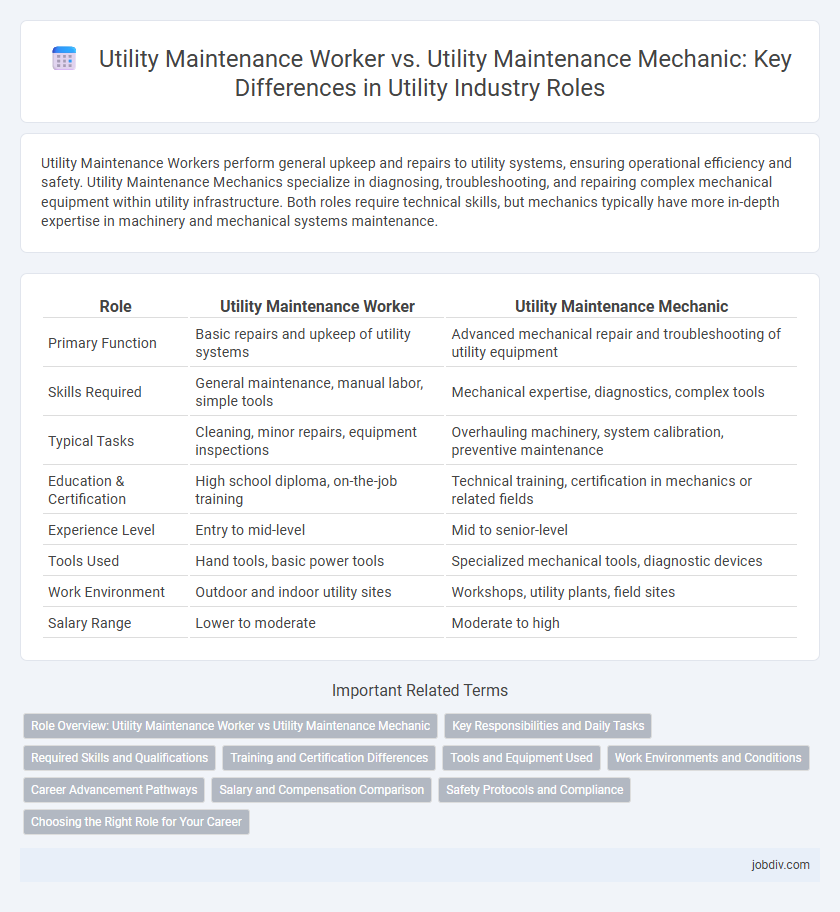

Utility Maintenance Workers perform general upkeep and repairs to utility systems, ensuring operational efficiency and safety. Utility Maintenance Mechanics specialize in diagnosing, troubleshooting, and repairing complex mechanical equipment within utility infrastructure. Both roles require technical skills, but mechanics typically have more in-depth expertise in machinery and mechanical systems maintenance.

Table of Comparison

| Role | Utility Maintenance Worker | Utility Maintenance Mechanic |

|---|---|---|

| Primary Function | Basic repairs and upkeep of utility systems | Advanced mechanical repair and troubleshooting of utility equipment |

| Skills Required | General maintenance, manual labor, simple tools | Mechanical expertise, diagnostics, complex tools |

| Typical Tasks | Cleaning, minor repairs, equipment inspections | Overhauling machinery, system calibration, preventive maintenance |

| Education & Certification | High school diploma, on-the-job training | Technical training, certification in mechanics or related fields |

| Experience Level | Entry to mid-level | Mid to senior-level |

| Tools Used | Hand tools, basic power tools | Specialized mechanical tools, diagnostic devices |

| Work Environment | Outdoor and indoor utility sites | Workshops, utility plants, field sites |

| Salary Range | Lower to moderate | Moderate to high |

Role Overview: Utility Maintenance Worker vs Utility Maintenance Mechanic

Utility Maintenance Workers perform routine inspections, repairs, and upkeep of utility systems such as water, gas, and electrical networks to ensure operational efficiency. Utility Maintenance Mechanics focus on diagnosing complex mechanical issues, overhauling machinery, and conducting preventive maintenance on equipment like pumps, generators, and valves within utility infrastructure. Both roles are critical for sustaining continuous utility service but differ in technical complexity and specialization.

Key Responsibilities and Daily Tasks

Utility Maintenance Workers perform routine inspections, repair utility infrastructure such as water lines and electrical systems, and handle emergency repairs to maintain continuous service. Utility Maintenance Mechanics specialize in diagnosing mechanical failures, overhauling equipment like pumps, valves, and motors, and ensuring proper functionality of complex utility machinery. Both roles require collaboration for system upkeep but differ in technical expertise and scope of mechanical repairs.

Required Skills and Qualifications

Utility Maintenance Workers typically require strong troubleshooting skills, proficiency in electrical and mechanical repairs, and basic knowledge of safety protocols. Utility Maintenance Mechanics need advanced technical qualifications, including certification in mechanical and electrical systems, expertise in diagnosing complex equipment malfunctions, and experience with preventive maintenance practices. Both roles demand physical stamina, attention to detail, and the ability to read technical manuals and blueprints.

Training and Certification Differences

Utility Maintenance Workers often require basic vocational training and on-the-job experience, focusing on general maintenance tasks such as equipment inspection and minor repairs. Utility Maintenance Mechanics typically complete advanced technical training programs and obtain certifications like HVAC, electrical, or mechanical licenses to handle complex machinery maintenance and troubleshooting. Certification levels distinguish these roles, with Mechanics usually mandated to meet higher standards to ensure compliance with safety and operational regulations.

Tools and Equipment Used

Utility Maintenance Workers primarily handle general repair tools such as wrenches, hammers, and basic power tools for routine maintenance tasks. Utility Maintenance Mechanics use specialized diagnostic equipment, pneumatic tools, and advanced machinery calibration instruments to perform precise mechanical repairs and system troubleshooting. Both roles require proficiency with safety gear, but Mechanics often operate more complex devices like hydraulic lifts and computerized control panels.

Work Environments and Conditions

Utility Maintenance Workers typically perform tasks in a variety of outdoor and indoor settings, often facing unpredictable weather conditions and physically demanding environments such as construction sites or utility plants. Utility Maintenance Mechanics usually work in more controlled environments, including workshops and industrial facilities, where they focus on repairing and maintaining complex mechanical systems. Both roles require adherence to safety protocols and may involve exposure to hazardous materials and heavy machinery.

Career Advancement Pathways

Utility Maintenance Workers often start with foundational skills in equipment upkeep and basic repairs, allowing them to gain experience in maintaining utility infrastructure. Utility Maintenance Mechanics typically possess advanced technical certifications and specialize in diagnosing and fixing complex mechanical and electrical issues, positioning them for supervisory or technical expert roles. Career advancement pathways frequently involve progressing from hands-on maintenance tasks to roles in management, system design, or specialized technical troubleshooting within utility companies.

Salary and Compensation Comparison

Utility Maintenance Workers typically earn an average annual salary ranging from $35,000 to $50,000, while Utility Maintenance Mechanics command higher wages, often between $45,000 and $65,000 due to specialized technical skills and certifications. Compensation packages for Utility Maintenance Mechanics frequently include overtime pay and performance bonuses, reflecting their advanced expertise in maintaining complex mechanical systems. Salary differentials are influenced by experience, geographic location, and the complexity of the utility infrastructure being serviced.

Safety Protocols and Compliance

Utility Maintenance Workers and Utility Maintenance Mechanics both adhere strictly to safety protocols and compliance standards set by OSHA and industry regulations. Maintenance Mechanics often engage with complex mechanical systems requiring specialized safety training in lockout/tagout and hazardous material handling. Utility Maintenance Workers focus on general upkeep while ensuring all safety measures are followed to prevent accidents and maintain regulatory compliance.

Choosing the Right Role for Your Career

Utility Maintenance Workers perform general upkeep and repair tasks on utility systems, handling a variety of physical and technical duties that ensure daily operations run smoothly. Utility Maintenance Mechanics specialize in diagnosing, troubleshooting, and repairing complex mechanical and electrical equipment, requiring advanced technical skills and certifications. Selecting the right career path depends on your technical expertise, interest in hands-on problem-solving, and desire for specialized training in utility system mechanics.

Utility Maintenance Worker vs Utility Maintenance Mechanic Infographic

jobdiv.com

jobdiv.com