Utility mechanics specialize in maintaining and repairing mechanical systems such as engines, HVAC units, and plumbing infrastructure, ensuring optimal performance and safety. Utility electricians focus on installing, troubleshooting, and repairing electrical systems, including wiring, transformers, and circuit breakers within utility services. Both roles are essential for reliable utility operations, balancing mechanical expertise with electrical proficiency.

Table of Comparison

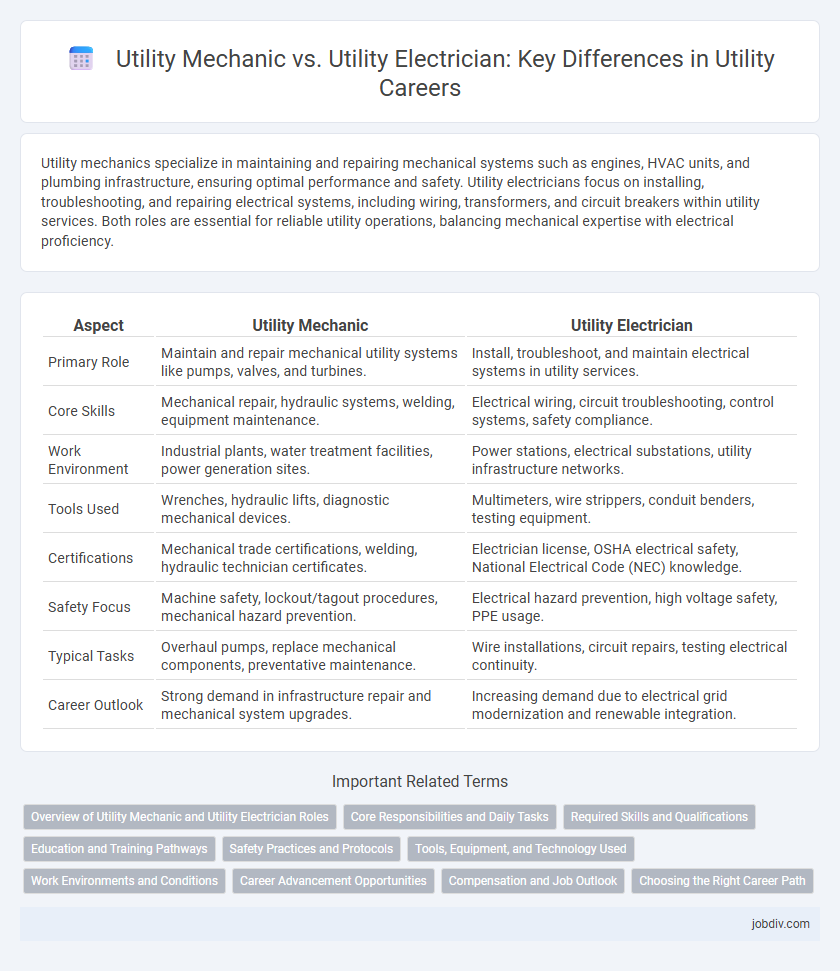

| Aspect | Utility Mechanic | Utility Electrician |

|---|---|---|

| Primary Role | Maintain and repair mechanical utility systems like pumps, valves, and turbines. | Install, troubleshoot, and maintain electrical systems in utility services. |

| Core Skills | Mechanical repair, hydraulic systems, welding, equipment maintenance. | Electrical wiring, circuit troubleshooting, control systems, safety compliance. |

| Work Environment | Industrial plants, water treatment facilities, power generation sites. | Power stations, electrical substations, utility infrastructure networks. |

| Tools Used | Wrenches, hydraulic lifts, diagnostic mechanical devices. | Multimeters, wire strippers, conduit benders, testing equipment. |

| Certifications | Mechanical trade certifications, welding, hydraulic technician certificates. | Electrician license, OSHA electrical safety, National Electrical Code (NEC) knowledge. |

| Safety Focus | Machine safety, lockout/tagout procedures, mechanical hazard prevention. | Electrical hazard prevention, high voltage safety, PPE usage. |

| Typical Tasks | Overhaul pumps, replace mechanical components, preventative maintenance. | Wire installations, circuit repairs, testing electrical continuity. |

| Career Outlook | Strong demand in infrastructure repair and mechanical system upgrades. | Increasing demand due to electrical grid modernization and renewable integration. |

Overview of Utility Mechanic and Utility Electrician Roles

Utility mechanics specialize in installing, maintaining, and repairing mechanical equipment such as pipes, valves, and heavy machinery essential for utility services. Utility electricians focus on electrical systems, including wiring, transformers, and circuit breakers, ensuring power distribution reliability in utility infrastructures. Both roles require technical skills and knowledge of safety protocols but differ primarily in their specialization within mechanical and electrical utility operations.

Core Responsibilities and Daily Tasks

Utility mechanics specialize in installing, maintaining, and repairing mechanical systems such as pumps, valves, and plumbing infrastructure in utility services. Utility electricians focus on electrical components, including wiring, circuit breakers, transformers, and electrical distribution systems critical for power delivery. Both roles require troubleshooting skills and adherence to safety protocols, but mechanics emphasize mechanical maintenance while electricians handle electrical system integrity.

Required Skills and Qualifications

Utility Mechanics require strong mechanical aptitude, experience with hydraulic and pneumatic systems, and proficiency in maintenance and repair of heavy machinery and equipment. Utility Electricians must possess a solid understanding of electrical systems, circuitry, and safety protocols, along with certifications such as OSHA and NFPA 70E compliance to handle high-voltage installations and troubleshooting. Both roles demand problem-solving skills and knowledge of industry regulations, but Utility Electricians typically need formal electrical training and licensing, whereas Utility Mechanics prioritize hands-on mechanical expertise and technical certifications.

Education and Training Pathways

Utility mechanics typically undergo technical training programs emphasizing mechanical systems, hydraulics, and preventive maintenance, often complemented by apprenticeships lasting 4-5 years. Utility electricians focus on electrical theory, wiring, circuit diagnostics, and safety protocols, requiring completion of an electrical apprenticeship or accredited vocational courses totaling around 8,000 hours. Both careers demand certifications aligned with industry standards, but utility electricians usually need a license to operate legally, reflecting the specialized electrical training pathway.

Safety Practices and Protocols

Utility mechanics follow rigorous safety practices such as lockout/tagout procedures, heavy machinery operation protocols, and personal protective equipment (PPE) usage to prevent accidents during mechanical maintenance and repairs. Utility electricians prioritize electrical safety standards including voltage testing, grounding, insulation verification, and adherence to National Electrical Code (NEC) regulations to mitigate risks related to electrical hazards. Both roles emphasize strict compliance with Occupational Safety and Health Administration (OSHA) guidelines to ensure workplace safety and minimize injury risks in utility environments.

Tools, Equipment, and Technology Used

Utility mechanics primarily use hand tools such as wrenches, hammers, and pipe cutters along with heavy machinery including excavators and hydraulic lifts for maintenance and repair of mechanical systems. Utility electricians rely on multimeters, voltage testers, conduit benders, and advanced diagnostic devices to install and troubleshoot electrical wiring and systems. Both professions increasingly incorporate smart technology and digital monitoring equipment to enhance precision, safety, and efficiency in utility infrastructure management.

Work Environments and Conditions

Utility mechanics typically work in industrial sites, infrastructure facilities, and outdoor environments where they handle mechanical systems such as pumps, valves, and engines. Utility electricians operate in similar settings but focus on electrical systems, wiring, and controls within power plants, substations, and distribution networks. Both roles often require working in challenging weather conditions, confined spaces, and compliance with strict safety regulations to ensure uninterrupted utility services.

Career Advancement Opportunities

Utility mechanics often advance by specializing in equipment maintenance, supervisory roles, or transitioning into industrial machinery operation, leveraging hands-on technical expertise. Utility electricians have career growth opportunities through mastering electrical systems design, project management, or obtaining certifications like Journeyman or Master Electrician that open doors to higher-paying leadership roles. Both paths offer upward mobility, but electricians typically encounter broader prospects in infrastructure projects and regulatory compliance sectors.

Compensation and Job Outlook

Utility mechanics typically earn a median annual wage of around $54,000, with steady demand driven by infrastructure maintenance and repair. Utility electricians often command higher salaries, averaging about $62,000 per year, due to specialized skills in electrical systems and increased safety requirements. Job outlook for both roles remains strong, with a projected growth rate of 5-7% over the next decade as utility companies invest in upgrading aging networks and expanding renewable energy sources.

Choosing the Right Career Path

Utility Mechanics specialize in maintaining and repairing mechanical systems such as pumps, compressors, and turbines critical to utility operations. Utility Electricians focus on electrical systems, including power distribution, control panels, and wiring within utility plants. Selecting the right career depends on your strengths in mechanical problem-solving or electrical system expertise, alongside industry demand and certification requirements.

Utility Mechanic vs Utility Electrician Infographic

jobdiv.com

jobdiv.com