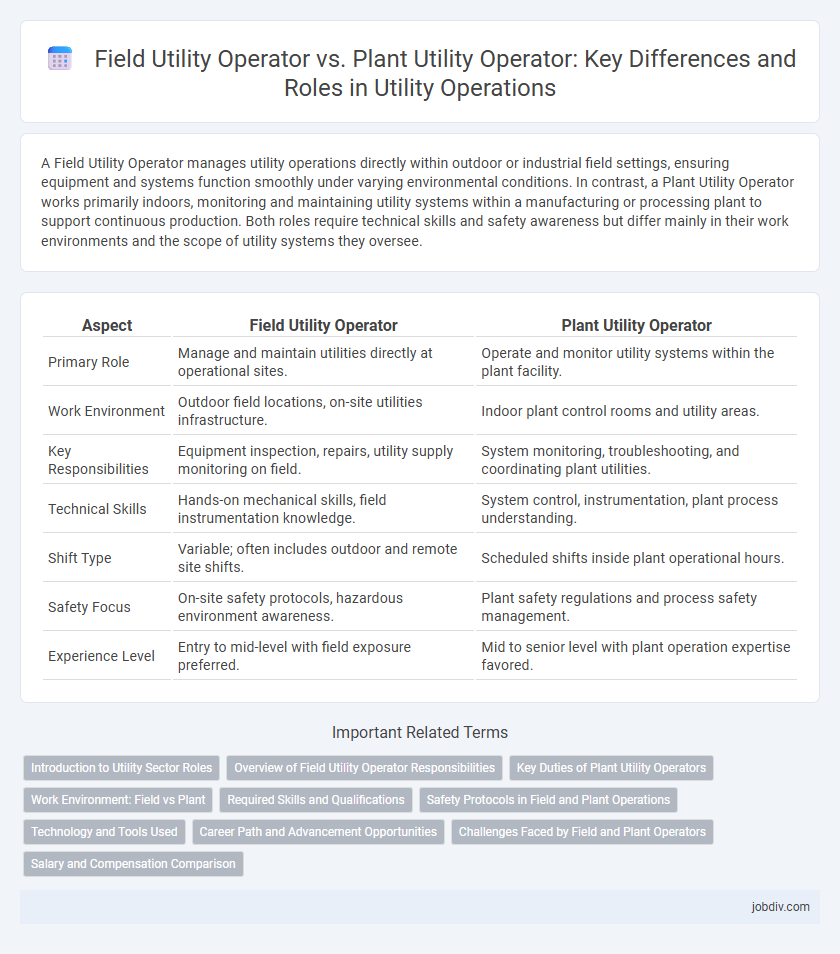

A Field Utility Operator manages utility operations directly within outdoor or industrial field settings, ensuring equipment and systems function smoothly under varying environmental conditions. In contrast, a Plant Utility Operator works primarily indoors, monitoring and maintaining utility systems within a manufacturing or processing plant to support continuous production. Both roles require technical skills and safety awareness but differ mainly in their work environments and the scope of utility systems they oversee.

Table of Comparison

| Aspect | Field Utility Operator | Plant Utility Operator |

|---|---|---|

| Primary Role | Manage and maintain utilities directly at operational sites. | Operate and monitor utility systems within the plant facility. |

| Work Environment | Outdoor field locations, on-site utilities infrastructure. | Indoor plant control rooms and utility areas. |

| Key Responsibilities | Equipment inspection, repairs, utility supply monitoring on field. | System monitoring, troubleshooting, and coordinating plant utilities. |

| Technical Skills | Hands-on mechanical skills, field instrumentation knowledge. | System control, instrumentation, plant process understanding. |

| Shift Type | Variable; often includes outdoor and remote site shifts. | Scheduled shifts inside plant operational hours. |

| Safety Focus | On-site safety protocols, hazardous environment awareness. | Plant safety regulations and process safety management. |

| Experience Level | Entry to mid-level with field exposure preferred. | Mid to senior level with plant operation expertise favored. |

Introduction to Utility Sector Roles

Field Utility Operators manage on-site equipment and systems, ensuring continuous operation of utilities such as steam, water, and compressed air. Plant Utility Operators oversee centralized utility facilities, optimizing energy distribution and maintaining supporting infrastructure for multiple production units. These roles are critical in maintaining operational efficiency and safety within industrial utility sectors.

Overview of Field Utility Operator Responsibilities

Field Utility Operators are responsible for maintaining and operating on-site utility equipment, ensuring continuous support for production processes by monitoring systems such as water treatment, air compressors, and steam generation. They perform routine inspections, troubleshoot equipment malfunctions, and execute preventive maintenance to minimize downtime within industrial or manufacturing environments. This role requires coordination with technical teams to adhere to safety protocols and optimize utility efficiency on the field level.

Key Duties of Plant Utility Operators

Plant Utility Operators are responsible for monitoring and maintaining critical equipment such as boilers, cooling towers, and water treatment systems to ensure continuous plant operations. They perform routine inspections, troubleshoot operational issues, and coordinate repair activities to optimize plant efficiency and safety. Unlike Field Utility Operators who manage utility services on-site in varying external locations, Plant Utility Operators focus primarily on internal plant systems and infrastructure.

Work Environment: Field vs Plant

Field Utility Operators typically work outdoors or at remote sites, often facing variable weather conditions and physically demanding tasks in open environments. Plant Utility Operators operate within controlled industrial settings, such as power plants or manufacturing facilities, with a focus on maintaining equipment and systems in a stable, indoor environment. The field environment requires adaptability to changing conditions and travel, while the plant environment emphasizes safety protocols and equipment monitoring in a consistent workspace.

Required Skills and Qualifications

Field Utility Operators require hands-on technical skills in equipment maintenance, troubleshooting, and real-time system monitoring, often needing certifications in safety protocols and mechanical operations. Plant Utility Operators must have strong analytical abilities to oversee plant-wide utility systems, with qualifications including knowledge of process control, regulatory compliance, and usually a background in engineering or industrial technology. Both roles demand physical stamina, attention to detail, and adherence to safety standards, but Plant Utility Operators typically engage in higher-level system analysis and coordination.

Safety Protocols in Field and Plant Operations

Field Utility Operators adhere to rigorous safety protocols tailored to outdoor environments, emphasizing hazard recognition, proper use of personal protective equipment (PPE), and emergency response procedures for equipment and weather-related risks. Plant Utility Operators follow strict safety measures within controlled environments, focusing on machinery operation, process monitoring, confined space entry, and compliance with OSHA standards to prevent incidents. Both roles require continuous safety training and adherence to industry regulations to ensure operational safety and minimize risk to personnel and infrastructure.

Technology and Tools Used

Field Utility Operators primarily utilize portable diagnostic tools, handheld meters, and mobile communication devices to monitor and maintain on-site utility equipment, ensuring real-time data collection and immediate troubleshooting. Plant Utility Operators rely on advanced control systems, SCADA (Supervisory Control and Data Acquisition) technology, and centralized monitoring software to manage facility-wide utility operations, optimizing energy use and maintaining regulatory compliance. Both roles integrate IoT-enabled sensors and automated reporting tools to enhance efficiency and accuracy in utility management.

Career Path and Advancement Opportunities

Field Utility Operators typically gain hands-on experience managing and maintaining utility systems on-site, positioning themselves for advancement into supervisory roles or specialized technical positions. Plant Utility Operators often work within centralized facilities, developing expertise in plant operations and process optimization, which can lead to careers in plant management or engineering support. Both roles offer pathways to leadership, with growth depending on gaining certifications, technical skills, and experience in complex utility operations.

Challenges Faced by Field and Plant Operators

Field Utility Operators face challenges such as variable environmental conditions, equipment accessibility, and immediate troubleshooting demands, which require adaptability and on-the-spot problem-solving skills. Plant Utility Operators contend with maintaining system stability, managing continuous operation of complex machinery, and coordinating with multiple departments to optimize plant performance. Both roles demand specialized technical knowledge, but Field Operators often deal with unpredictable external factors while Plant Operators focus on internal system optimization and compliance.

Salary and Compensation Comparison

Field Utility Operators typically earn between $40,000 and $55,000 annually, reflecting their on-site responsibilities and operational tasks in various utility settings. Plant Utility Operators command slightly higher salaries, ranging from $50,000 to $65,000, due to their specialized skills in maintaining and overseeing plant systems. Compensation packages for Plant Utility Operators often include additional benefits such as shift differentials and performance bonuses, enhancing their overall earnings potential compared to Field Utility Operators.

Field Utility Operator vs Plant Utility Operator Infographic

jobdiv.com

jobdiv.com