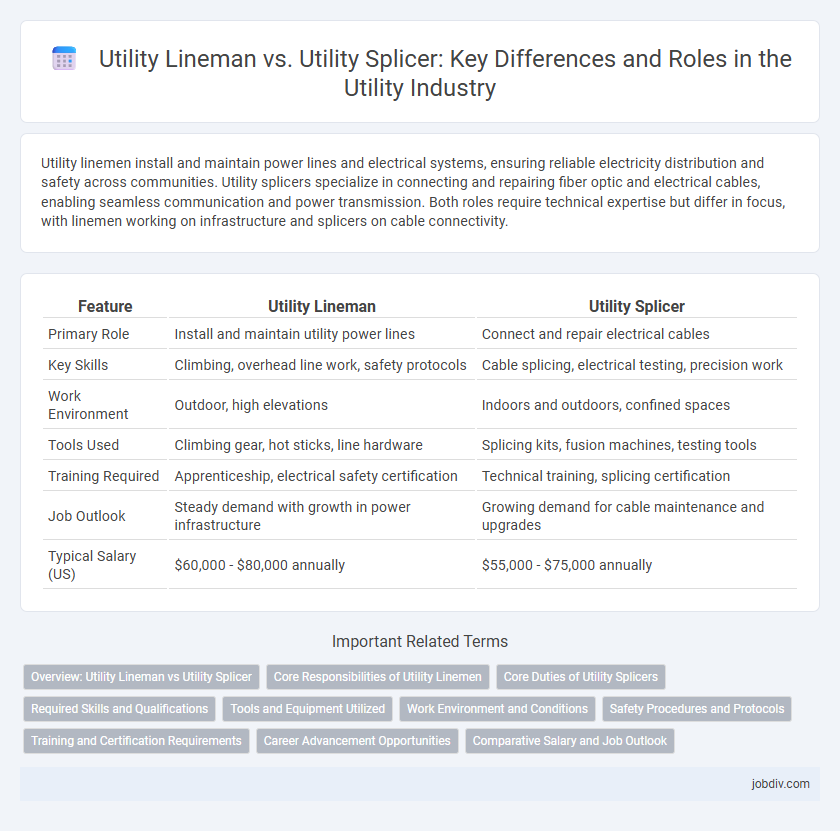

Utility linemen install and maintain power lines and electrical systems, ensuring reliable electricity distribution and safety across communities. Utility splicers specialize in connecting and repairing fiber optic and electrical cables, enabling seamless communication and power transmission. Both roles require technical expertise but differ in focus, with linemen working on infrastructure and splicers on cable connectivity.

Table of Comparison

| Feature | Utility Lineman | Utility Splicer |

|---|---|---|

| Primary Role | Install and maintain utility power lines | Connect and repair electrical cables |

| Key Skills | Climbing, overhead line work, safety protocols | Cable splicing, electrical testing, precision work |

| Work Environment | Outdoor, high elevations | Indoors and outdoors, confined spaces |

| Tools Used | Climbing gear, hot sticks, line hardware | Splicing kits, fusion machines, testing tools |

| Training Required | Apprenticeship, electrical safety certification | Technical training, splicing certification |

| Job Outlook | Steady demand with growth in power infrastructure | Growing demand for cable maintenance and upgrades |

| Typical Salary (US) | $60,000 - $80,000 annually | $55,000 - $75,000 annually |

Overview: Utility Lineman vs Utility Splicer

Utility linemen install, maintain, and repair overhead and underground power lines, ensuring reliable electricity distribution across transmission and distribution networks. Utility splicers specialize in connecting and repairing electrical cables, using techniques such as mechanical or fusion splicing to restore continuity and prevent outages. Both roles are critical for utility infrastructure, with linemen focusing on physical line work and splicers targeting cable integrity and connectivity.

Core Responsibilities of Utility Linemen

Utility linemen are primarily responsible for installing, maintaining, and repairing overhead and underground power lines to ensure reliable electricity distribution. They work with high-voltage cables, transformers, and other electrical equipment, often climbing poles or using bucket trucks to perform their tasks safely at heights. Utility linemen also perform routine inspections and emergency repairs to minimize power outages and maintain public safety.

Core Duties of Utility Splicers

Utility Splicers specialize in connecting and repairing electrical power lines by joining cables to ensure efficient electrical transmission and distribution. Their core duties include splicing underground and overhead power cables, testing cable connections for integrity, and troubleshooting faults to maintain power reliability. They work closely with utility linemen but focus primarily on cable preparation and restoration, enabling the continuous flow of electricity across the grid.

Required Skills and Qualifications

Utility linemen require strong physical stamina, knowledge of electrical systems, and the ability to work at heights and in adverse weather conditions, with certifications such as OSHA safety training and commercial driver's licenses often necessary. Utility splicers need advanced technical skills in fiber optic and copper cable splicing, keen attention to detail, and expertise in using specialized tools, typically supported by certifications in cable splicing and telecommunications. Both roles demand problem-solving abilities, adherence to strict safety standards, and effective communication skills for successful collaboration in utility maintenance and repair.

Tools and Equipment Utilized

Utility linemen primarily use climbing gear, hot sticks, and hydraulic tools to install and maintain power lines, while utility splicers specialize in cable splicing equipment, fusion splicers, and ground testing devices to join and repair electrical cables. Linemen rely on insulated gloves, bucket trucks, and fall protection systems for safety during high-voltage work. Splicers utilize precision tools like cleaving tools, heat shrink tubing, and testing meters to ensure optimal cable connectivity and electrical integrity.

Work Environment and Conditions

Utility linemen work primarily outdoors on power lines, often in challenging weather conditions such as rain, wind, and extreme temperatures, requiring physical endurance and safety precautions. Utility splicers typically perform tasks in more controlled environments, including underground vaults or utility poles, focusing on connecting and repairing electrical cables with precision. Both roles involve elevated safety risks but differ in their typical work settings, with linemen facing more exposure to environmental hazards and splicers working in confined spaces.

Safety Procedures and Protocols

Utility linemen follow stringent safety procedures, including wearing insulated gloves, maintaining minimum approach distances, and using fall protection to prevent electrical hazards and falls. Utility splicers adhere to specific protocols for handling live wires, such as de-energizing circuits before splicing, using insulated tools, and conducting thorough testing to ensure secure connections. Both roles require compliance with Occupational Safety and Health Administration (OSHA) standards and regular safety training to minimize risks associated with high-voltage equipment.

Training and Certification Requirements

Utility linemen require extensive training focused on installing and maintaining overhead and underground power lines, often completing apprenticeships followed by obtaining certifications such as OSHA safety standards and commercial driver's licenses. Utility splicers specialize in joining and repairing electrical cables, necessitating precise technical training in cable splicing techniques, fiber optics, and certifications from organizations like the Electrical Training Alliance or NCCER. Both roles demand rigorous safety training and ongoing certification renewals to handle high-voltage equipment and ensure compliance with industry regulations.

Career Advancement Opportunities

Utility linemen primarily focus on installing, maintaining, and repairing power lines, which provides foundational skills and hands-on experience for career advancement in the utility sector. Utility splicers specialize in connecting and repairing cables, offering advanced technical expertise that can lead to higher-paying supervisory or technical specialist roles. Career progression for both roles often includes certifications, additional training, and transitioning into management or engineering positions within utility companies.

Comparative Salary and Job Outlook

Utility linemen typically earn an average annual salary ranging from $60,000 to $75,000, while utility splicers often command higher wages, averaging between $70,000 and $85,000 due to their specialized skills in cable splicing and maintenance. Employment growth for utility linemen is projected at 5% over the next decade, slightly below the 7% growth expected for utility splicers, reflecting increased demand for advanced electrical infrastructure and fiber optic networks. Both careers offer strong job stability, but utility splicers benefit from a more favorable salary trajectory and expanding opportunities in high-voltage and telecommunications sectors.

Utility Lineman vs Utility Splicer Infographic

jobdiv.com

jobdiv.com