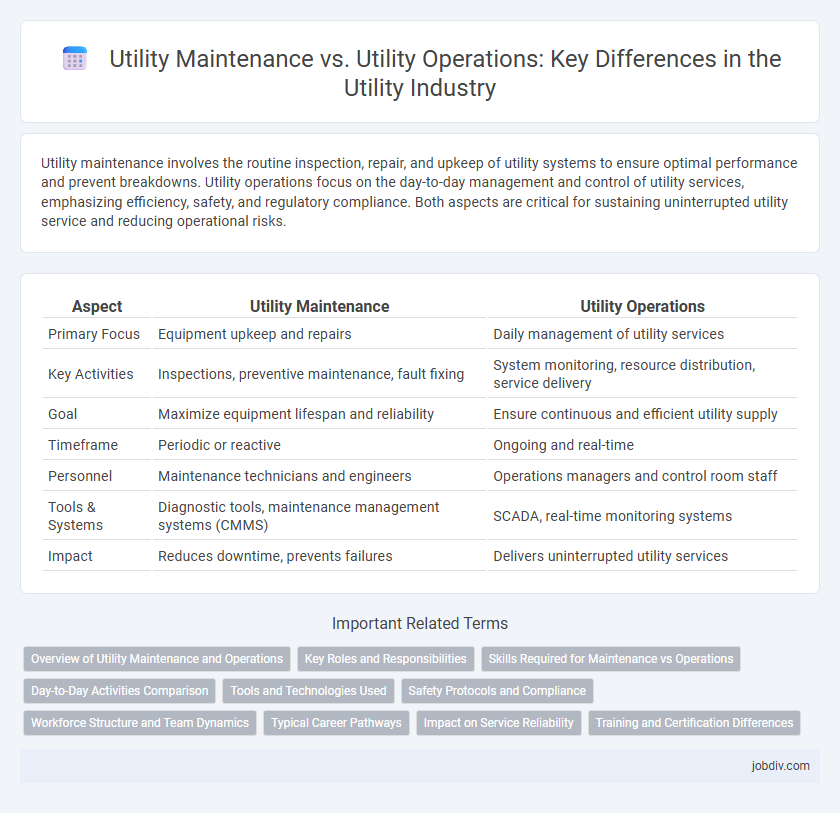

Utility maintenance involves the routine inspection, repair, and upkeep of utility systems to ensure optimal performance and prevent breakdowns. Utility operations focus on the day-to-day management and control of utility services, emphasizing efficiency, safety, and regulatory compliance. Both aspects are critical for sustaining uninterrupted utility service and reducing operational risks.

Table of Comparison

| Aspect | Utility Maintenance | Utility Operations |

|---|---|---|

| Primary Focus | Equipment upkeep and repairs | Daily management of utility services |

| Key Activities | Inspections, preventive maintenance, fault fixing | System monitoring, resource distribution, service delivery |

| Goal | Maximize equipment lifespan and reliability | Ensure continuous and efficient utility supply |

| Timeframe | Periodic or reactive | Ongoing and real-time |

| Personnel | Maintenance technicians and engineers | Operations managers and control room staff |

| Tools & Systems | Diagnostic tools, maintenance management systems (CMMS) | SCADA, real-time monitoring systems |

| Impact | Reduces downtime, prevents failures | Delivers uninterrupted utility services |

Overview of Utility Maintenance and Operations

Utility maintenance involves regular inspections, repairs, and system upkeep to ensure infrastructure reliability and minimize downtime. Utility operations focus on the day-to-day management and control of utility services, including power distribution, water treatment, and waste management. Effective coordination between maintenance and operations enhances service efficiency, reduces outages, and extends asset lifespan.

Key Roles and Responsibilities

Utility maintenance involves scheduled inspections, repairs, and replacements to ensure infrastructure reliability and prevent service disruptions. Utility operations manage the day-to-day functioning of systems, including monitoring performance, controlling equipment, and responding to emergencies. Key roles in maintenance emphasize technical skills and predictive analytics, while operations require real-time decision-making and coordination across multiple departments.

Skills Required for Maintenance vs Operations

Utility maintenance demands technical proficiency in troubleshooting, equipment repair, and preventive care to ensure consistent infrastructure performance. Utility operations require strong analytical skills, real-time monitoring capabilities, and decision-making expertise to manage energy distribution and system reliability efficiently. Both roles require knowledge of safety protocols, regulatory compliance, and the ability to interpret utility data for optimal service delivery.

Day-to-Day Activities Comparison

Utility maintenance centers on routine inspections, equipment repairs, and preventative measures to ensure infrastructure reliability and minimize downtime. Utility operations manage the real-time control of energy distribution, monitoring system performance, and responding to fluctuations or emergencies to maintain consistent service delivery. Together, they support the continuous functionality and efficiency of utility services through complementary daily activities.

Tools and Technologies Used

Utility maintenance relies heavily on diagnostic tools such as infrared thermography, ultrasonic leak detectors, and predictive analytics software to identify and prevent equipment failures. Utility operations utilize SCADA (Supervisory Control and Data Acquisition) systems, GIS mapping, and automated meter reading (AMR) technologies to manage real-time resource distribution and monitor network performance. Integration of IoT sensors and advanced data analytics enhances both maintenance scheduling and operational efficiency by providing detailed insights and enabling proactive decision-making.

Safety Protocols and Compliance

Utility maintenance prioritizes rigorous safety protocols to prevent equipment failures and ensure worker protection during repairs, adhering strictly to OSHA and industry-specific safety regulations. Utility operations focus on continuous compliance with environmental and safety standards while managing real-time system performance to avoid hazards and service interruptions. Both domains require detailed documentation and regular audits to meet federal and state compliance mandates, enhancing overall utility reliability and safety.

Workforce Structure and Team Dynamics

Utility maintenance typically involves specialized technicians focused on asset upkeep, repairs, and preventive measures, forming a workforce structured around field crews and maintenance planners. Utility operations encompass a broader team including control room operators, system dispatchers, and engineers who manage real-time system performance and customer service delivery. Effective workforce coordination between maintenance and operations teams enhances reliability, reduces downtime, and optimizes resource allocation across utility functions.

Typical Career Pathways

Utility maintenance careers often begin with roles as technicians or mechanics specializing in repairing and servicing infrastructure such as electrical grids, water systems, or gas pipelines. Utility operations professionals typically start as operators or control room specialists managing real-time system performance and ensuring continuous service delivery. Both pathways offer progression to supervisory or managerial positions, with maintenance focusing on asset reliability and operations emphasizing system efficiency and regulatory compliance.

Impact on Service Reliability

Utility maintenance ensures the continuous reliability of infrastructure by preventing equipment failures through scheduled inspections, repairs, and upgrades. Utility operations manage the real-time distribution and flow of services, adjusting to demand fluctuations and emergencies to maintain consistent service delivery. Coordinated maintenance reduces downtime and operational disruptions, directly enhancing overall service reliability for customers.

Training and Certification Differences

Utility maintenance requires specialized training in equipment diagnostics, repair techniques, and safety protocols to ensure reliable system performance. Utility operations focus on certification programs that emphasize system management, process optimization, and regulatory compliance to maintain efficient service delivery. Distinct training paths ensure maintenance technicians develop hands-on technical skills while operators gain expertise in operational control and monitoring systems.

Utility Maintenance vs Utility Operations Infographic

jobdiv.com

jobdiv.com