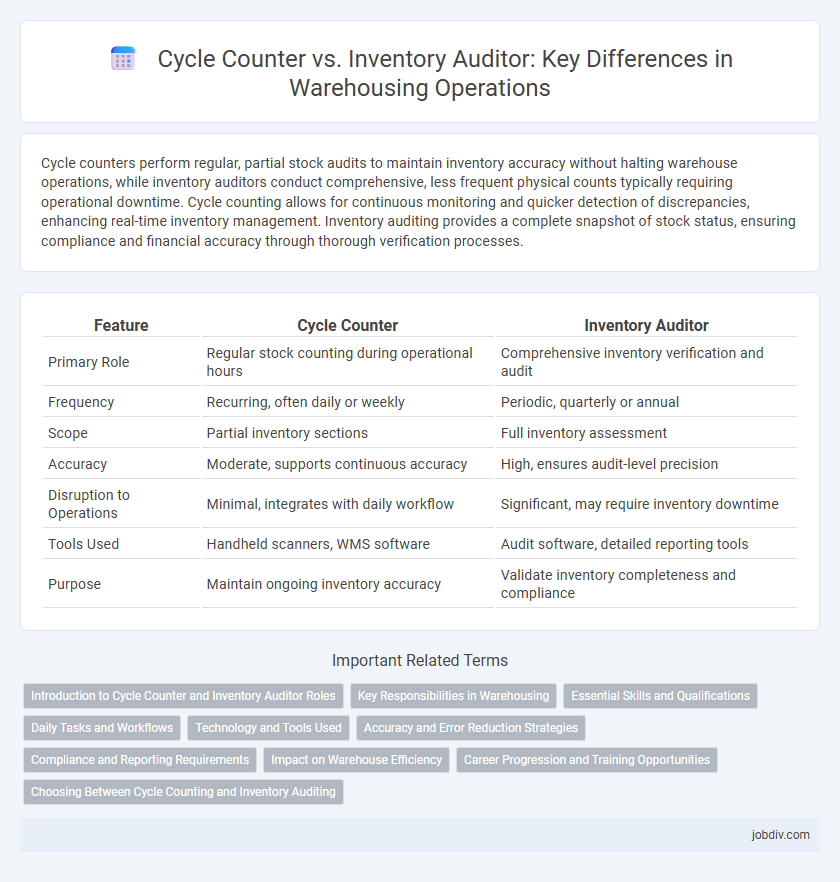

Cycle counters perform regular, partial stock audits to maintain inventory accuracy without halting warehouse operations, while inventory auditors conduct comprehensive, less frequent physical counts typically requiring operational downtime. Cycle counting allows for continuous monitoring and quicker detection of discrepancies, enhancing real-time inventory management. Inventory auditing provides a complete snapshot of stock status, ensuring compliance and financial accuracy through thorough verification processes.

Table of Comparison

| Feature | Cycle Counter | Inventory Auditor |

|---|---|---|

| Primary Role | Regular stock counting during operational hours | Comprehensive inventory verification and audit |

| Frequency | Recurring, often daily or weekly | Periodic, quarterly or annual |

| Scope | Partial inventory sections | Full inventory assessment |

| Accuracy | Moderate, supports continuous accuracy | High, ensures audit-level precision |

| Disruption to Operations | Minimal, integrates with daily workflow | Significant, may require inventory downtime |

| Tools Used | Handheld scanners, WMS software | Audit software, detailed reporting tools |

| Purpose | Maintain ongoing inventory accuracy | Validate inventory completeness and compliance |

Introduction to Cycle Counter and Inventory Auditor Roles

Cycle counters systematically verify inventory quantities on a regular basis, ensuring accurate stock records without requiring full warehouse shutdowns. Inventory auditors conduct comprehensive audits to assess inventory accuracy, compliance, and financial integrity through detailed inspections and reconciliation processes. Both roles are critical for maintaining inventory accuracy, reducing discrepancies, and supporting operational efficiency in warehousing management.

Key Responsibilities in Warehousing

Cycle counters in warehousing are responsible for performing regular, scheduled counts of inventory to ensure accuracy and identify discrepancies without fully disrupting warehouse operations. Inventory auditors focus on a comprehensive review of stock records and physical inventory, verifying data accuracy, compliance with standards, and identifying systemic issues or fraud. Both roles are crucial for maintaining inventory integrity but differ in scope, with cycle counters emphasizing ongoing inventory accuracy and inventory auditors conducting in-depth evaluations.

Essential Skills and Qualifications

Cycle counters require strong attention to detail and proficiency in inventory management software to perform frequent stock verifications accurately, along with excellent organizational skills to track discrepancies efficiently. Inventory auditors demand expertise in audit procedures, financial reporting, and regulatory compliance, coupled with analytical skills to evaluate inventory accuracy and internal controls comprehensively. Both roles benefit from knowledge of warehouse operations and effective communication skills to collaborate with inventory and finance teams.

Daily Tasks and Workflows

Cycle counters perform regular, scheduled counts of specific inventory sections to ensure accuracy and promptly identify discrepancies. Inventory auditors conduct comprehensive inventory reviews, analyzing data trends, verifying stock accuracy, and ensuring compliance with company policies. Daily tasks for cycle counters include scanning SKUs and updating records, while inventory auditors focus on cross-referencing inventory reports and investigating variances.

Technology and Tools Used

Cycle counters utilize handheld barcode scanners and mobile inventory management software to conduct real-time stocktaking with high accuracy. Inventory auditors often employ RFID technology combined with advanced audit software to perform comprehensive verification and analysis of warehouse inventory data. Both roles leverage cloud-based platforms and data analytics tools to enhance inventory visibility and streamline reporting processes.

Accuracy and Error Reduction Strategies

Cycle counters employ systematic, frequent partial counts to enhance real-time accuracy and rapidly identify discrepancies within warehouse inventory. Inventory auditors conduct comprehensive, periodic audits that validate overall stock integrity, often uncovering hidden errors and inconsistencies through detailed reconciliations. Combining cycle counting with targeted auditor reviews significantly reduces inventory errors and supports continuous improvement in warehouse inventory accuracy.

Compliance and Reporting Requirements

Cycle counters conduct regular, systematic partial counts to maintain inventory accuracy and support compliance with internal controls and external audit standards. Inventory auditors perform comprehensive reviews, verifying inventory valuation and adherence to regulatory reporting requirements such as SOX and GAAP. Both roles are essential for ensuring accurate financial reporting and regulatory compliance in warehousing operations.

Impact on Warehouse Efficiency

Cycle counters enhance warehouse efficiency by performing regular, targeted stock verifications that minimize disruptions and maintain accurate inventory records. Inventory auditors conduct comprehensive, periodic audits that ensure overall inventory integrity but can temporarily halt operations and reduce productivity. Balancing both methods enables warehouses to sustain accuracy while optimizing workflow and resource allocation.

Career Progression and Training Opportunities

Cycle Counters typically begin with hands-on experience in inventory tracking and gradually advance to Inventory Auditor roles, which require deeper analytical skills and understanding of auditing standards. Training for Cycle Counters often includes basic inventory management systems and accuracy techniques, while Inventory Auditors receive advanced education in audit methodologies, compliance regulations, and data analysis tools. Career progression from Cycle Counter to Inventory Auditor opens opportunities for leadership positions in warehouse management and supply chain optimization.

Choosing Between Cycle Counting and Inventory Auditing

Choosing between cycle counting and inventory auditing depends on the warehouse's operational goals and accuracy requirements. Cycle counting provides continuous, real-time inventory verification by regularly checking small sections, which reduces overall disruption and helps maintain inventory accuracy. Inventory auditing, on the other hand, involves comprehensive, periodic reviews of entire stock levels, offering thorough validation but requiring significant downtime and resource allocation.

Cycle Counter vs Inventory Auditor Infographic

jobdiv.com

jobdiv.com