Material handlers manage the movement and storage of raw materials and finished goods within a warehouse, ensuring efficient flow and organization. Order selectors specialize in picking and assembling products based on specific customer orders, playing a critical role in fulfilling shipments accurately. Both roles are essential for optimizing warehouse operations but focus on different stages of inventory management and order fulfillment.

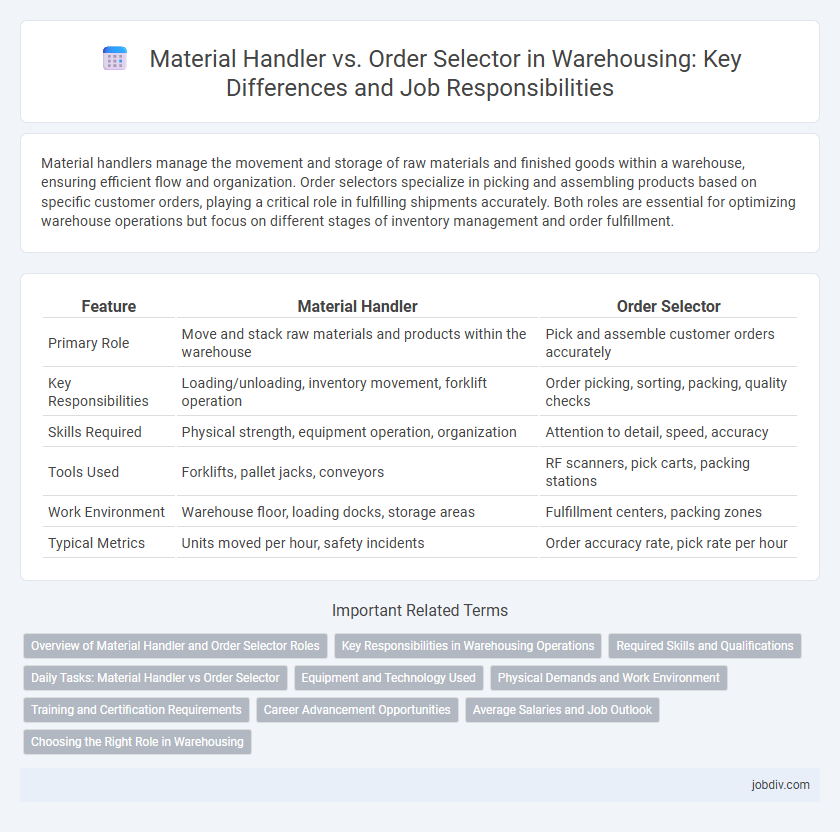

Table of Comparison

| Feature | Material Handler | Order Selector |

|---|---|---|

| Primary Role | Move and stack raw materials and products within the warehouse | Pick and assemble customer orders accurately |

| Key Responsibilities | Loading/unloading, inventory movement, forklift operation | Order picking, sorting, packing, quality checks |

| Skills Required | Physical strength, equipment operation, organization | Attention to detail, speed, accuracy |

| Tools Used | Forklifts, pallet jacks, conveyors | RF scanners, pick carts, packing stations |

| Work Environment | Warehouse floor, loading docks, storage areas | Fulfillment centers, packing zones |

| Typical Metrics | Units moved per hour, safety incidents | Order accuracy rate, pick rate per hour |

Overview of Material Handler and Order Selector Roles

Material handlers manage the receipt, storage, and movement of materials within a warehouse, ensuring efficient inventory control and timely deliveries. Order selectors specialize in accurately picking and packing products based on customer orders, optimizing order fulfillment speed and accuracy. Both roles are critical for maintaining seamless warehouse operations and meeting supply chain demands.

Key Responsibilities in Warehousing Operations

Material Handlers primarily manage the receipt, storage, and movement of goods within the warehouse, ensuring inventory accuracy and timely replenishment. Order Selectors focus on picking and preparing customer orders efficiently by selecting the right products based on order specifications and quality standards. Both roles are essential for maintaining streamlined warehousing operations, with Material Handlers emphasizing inventory control and Order Selectors prioritizing order accuracy and fulfillment speed.

Required Skills and Qualifications

Material handlers require strong physical stamina, attention to detail, and basic inventory management skills to efficiently move and store goods within the warehouse. Order selectors need advanced knowledge of warehouse management systems, precision in picking accuracy, and proficiency in operating forklifts or pallet jacks. Both roles demand adherence to safety protocols, teamwork abilities, and effective communication skills to maintain smooth warehouse operations.

Daily Tasks: Material Handler vs Order Selector

Material handlers primarily manage the receipt, storage, and movement of inventory within the warehouse, including unloading shipments, stacking products, and maintaining equipment. Order selectors focus on accurately picking and assembling customer orders based on specific requirements, ensuring timely and precise fulfillment. Both roles require strong attention to detail and efficiency but differ in their core daily tasks, with material handlers emphasizing inventory flow and order selectors prioritizing order accuracy.

Equipment and Technology Used

Material Handlers primarily operate forklifts, pallet jacks, and automated guided vehicles to move bulk materials efficiently within warehouses. Order Selectors utilize radio frequency (RF) scanners, pick-to-light systems, and conveyor belts to accurately retrieve and prepare individual items for shipment. Both roles leverage warehouse management systems (WMS) to optimize inventory tracking and workflow coordination.

Physical Demands and Work Environment

Material handlers face intense physical demands including heavy lifting, continuous walking, and operating forklifts in dynamic warehouse environments. Order selectors perform repetitive picking tasks often using pallet jacks and reach trucks, requiring agility and precision in fast-paced, climate-controlled settings. Both roles demand stamina and adherence to safety protocols amidst noise, machinery, and varying warehouse conditions.

Training and Certification Requirements

Material handlers typically require basic safety training and an understanding of warehouse equipment operation, with certifications such as OSHA Forklift Operator being advantageous. Order selectors need more specialized training in inventory management systems, pick-and-pack processes, and may require certifications in order picking technologies or quality control standards. Both roles emphasize safety compliance, but order selectors often undergo more rigorous training to ensure accuracy and efficiency in fulfilling customer orders within warehouse operations.

Career Advancement Opportunities

Material Handlers develop foundational skills in inventory management and equipment operation, providing a pathway to more specialized warehouse roles. Order Selectors gain expertise in picking accuracy and order fulfillment, often leading to supervisory or logistics coordinator positions. Progression from Material Handler to Order Selector typically results in increased responsibility and higher earning potential within warehousing careers.

Average Salaries and Job Outlook

Material Handlers typically earn an average salary ranging from $28,000 to $39,000 annually, while Order Selectors tend to have a slightly higher average salary, between $30,000 and $42,000 per year. The job outlook for Material Handlers is expected to grow about 5% over the next decade, reflecting stable demand in warehousing operations. Order Selectors face a similar or slightly faster growth rate of around 6%, driven by increasing e-commerce activities requiring efficient order fulfillment.

Choosing the Right Role in Warehousing

Material handlers primarily manage the movement, storage, and loading of inventory using forklifts and pallet jacks, ensuring efficient material flow in warehouses. Order selectors focus on accurately picking and preparing items to fulfill customer orders, often requiring attention to detail and speed. Selecting the right role depends on a candidate's skill set, whether it leans toward equipment operation and heavy lifting or precision and order accuracy.

Material Handler vs Order Selector Infographic

jobdiv.com

jobdiv.com