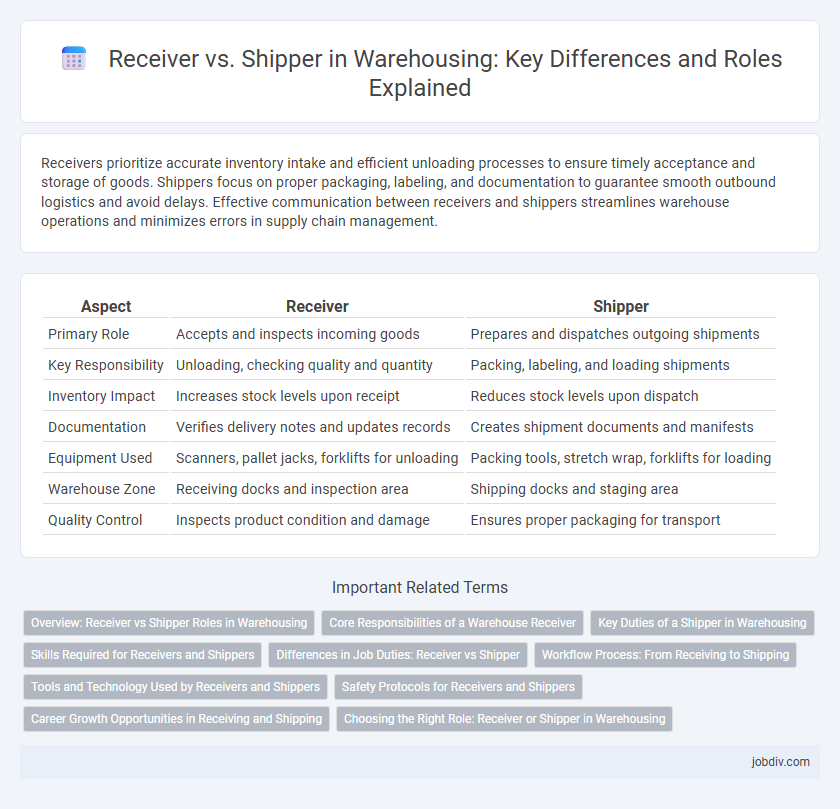

Receivers prioritize accurate inventory intake and efficient unloading processes to ensure timely acceptance and storage of goods. Shippers focus on proper packaging, labeling, and documentation to guarantee smooth outbound logistics and avoid delays. Effective communication between receivers and shippers streamlines warehouse operations and minimizes errors in supply chain management.

Table of Comparison

| Aspect | Receiver | Shipper |

|---|---|---|

| Primary Role | Accepts and inspects incoming goods | Prepares and dispatches outgoing shipments |

| Key Responsibility | Unloading, checking quality and quantity | Packing, labeling, and loading shipments |

| Inventory Impact | Increases stock levels upon receipt | Reduces stock levels upon dispatch |

| Documentation | Verifies delivery notes and updates records | Creates shipment documents and manifests |

| Equipment Used | Scanners, pallet jacks, forklifts for unloading | Packing tools, stretch wrap, forklifts for loading |

| Warehouse Zone | Receiving docks and inspection area | Shipping docks and staging area |

| Quality Control | Inspects product condition and damage | Ensures proper packaging for transport |

Overview: Receiver vs Shipper Roles in Warehousing

The receiver in warehousing is responsible for accepting incoming shipments, inspecting goods for accuracy and damage, and updating inventory records to ensure stock levels are accurate. The shipper oversees the preparation and dispatch of outgoing orders, ensuring correct packaging, labeling, and timely delivery to customers. Both roles are critical for maintaining efficient supply chain operations, minimizing errors, and ensuring smooth inventory flow.

Core Responsibilities of a Warehouse Receiver

Warehouse receivers are responsible for accurately inspecting incoming goods, verifying shipment contents against purchase orders, and ensuring proper documentation is completed for inventory records. They organize and safely store products in designated locations, maintaining warehouse order and accessibility. Their role is crucial in preventing errors, managing quality control, and facilitating efficient inventory management within the supply chain.

Key Duties of a Shipper in Warehousing

A shipper in warehousing is primarily responsible for accurately preparing and packaging goods for dispatch, ensuring all items match the order specifications and comply with safety standards. They coordinate shipment schedules, generate necessary documentation such as bills of lading, and communicate with carriers to guarantee timely and efficient delivery. Proper inventory management and verifying product quality before shipment are critical to minimizing errors and maintaining supply chain integrity.

Skills Required for Receivers and Shippers

Receivers require strong organizational skills, attention to detail, and proficiency in inventory management systems to accurately verify incoming shipments and manage stock levels. Shippers must possess effective communication skills, knowledge of packaging standards, and the ability to coordinate logistics to ensure timely and secure dispatch of goods. Both roles demand time management abilities and familiarity with warehouse safety protocols to maintain operational efficiency.

Differences in Job Duties: Receiver vs Shipper

Receivers primarily focus on inspecting incoming shipments, verifying accuracy against purchase orders, and organizing inventory for storage to ensure proper stock control. Shippers handle the packaging, labeling, and documentation of outbound goods, coordinating with carriers to ensure timely and accurate delivery. These distinct job duties highlight the receiver's role in quality control and inventory management versus the shipper's responsibility for order fulfillment and logistics coordination.

Workflow Process: From Receiving to Shipping

The workflow process in warehousing begins with the receiver verifying incoming shipments against purchase orders, inspecting for damages, and updating the inventory management system to ensure accurate stock levels. In contrast, the shipper is responsible for picking, packing, and staging outgoing orders, followed by coordinating transportation and confirming shipment details to guarantee timely delivery. Both roles are critical to maintaining operational efficiency, inventory accuracy, and customer satisfaction throughout the supply chain.

Tools and Technology Used by Receivers and Shippers

Receivers utilize barcode scanners, RFID technology, and warehouse management systems (WMS) to accurately track incoming inventory and automate data entry, enhancing receiving efficiency. Shippers rely on transportation management systems (TMS), automated packing machines, and label printers to optimize order fulfillment, shipping accuracy, and carrier coordination. Both roles leverage IoT sensors and cloud-based platforms to improve real-time visibility and streamline supply chain operations.

Safety Protocols for Receivers and Shippers

Receivers and shippers must adhere to strict safety protocols to prevent accidents and ensure smooth warehouse operations. Receivers should verify shipment documentation, inspect cargo for damage, and use proper personal protective equipment (PPE) when handling incoming goods. Shippers are responsible for securely packaging items, labeling hazardous materials correctly, and following weight limits to reduce risks during transportation and unloading.

Career Growth Opportunities in Receiving and Shipping

Careers in receiving and shipping offer distinct growth paths rooted in operational expertise and logistics management. Receiving roles focus on inventory control, quality inspection, and supplier communication, which can lead to positions like Inventory Manager or Quality Assurance Supervisor. Shipping careers emphasize order fulfillment, distribution logistics, and transportation coordination, providing advancement opportunities to roles such as Shipping Coordinator or Logistics Manager.

Choosing the Right Role: Receiver or Shipper in Warehousing

Choosing the right role between receiver and shipper in warehousing is crucial for optimizing inventory flow and minimizing errors. Receivers focus on accurate inspection, unloading, and documentation of incoming goods, ensuring inventory accuracy and quality control. Shippers manage the picking, packing, and timely dispatch of outbound shipments, directly impacting delivery speed and customer satisfaction.

Receiver vs Shipper Infographic

jobdiv.com

jobdiv.com