Forklift drivers operate powered industrial trucks to lift, move, and stack heavy loads efficiently within warehouses, handling larger and bulkier items than pallet jack operators. Pallet jack operators maneuver manual or electric pallet jacks to transport pallets short distances, ideal for confined spaces and lighter loads. Both roles require precision and safety awareness, but forklift drivers often need formal certification due to the complexity and risk associated with operating heavier machinery.

Table of Comparison

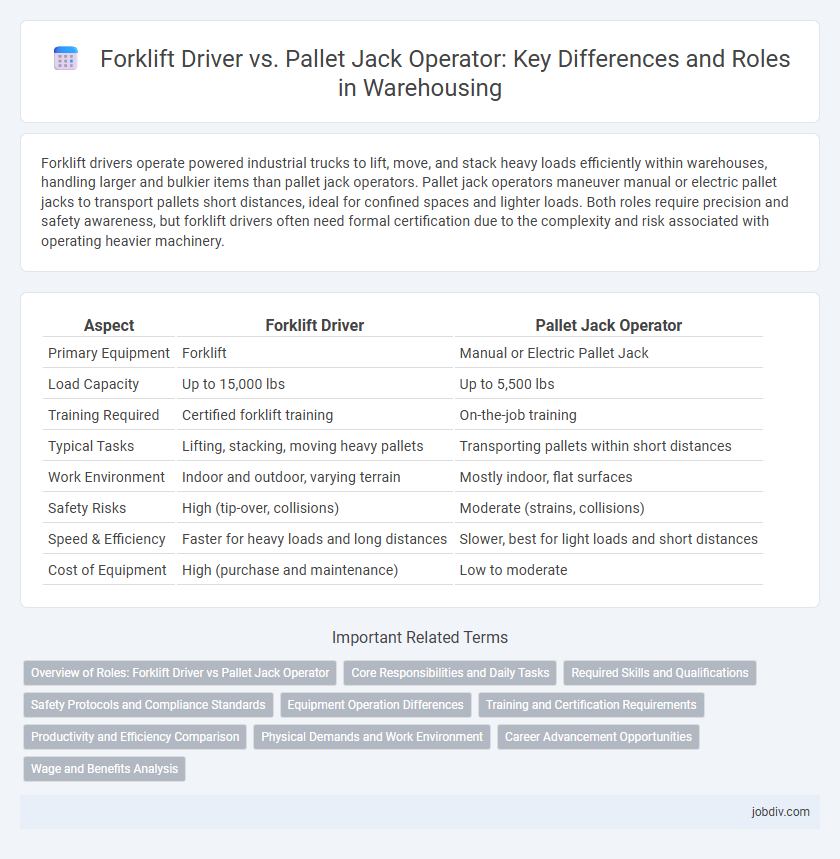

| Aspect | Forklift Driver | Pallet Jack Operator |

|---|---|---|

| Primary Equipment | Forklift | Manual or Electric Pallet Jack |

| Load Capacity | Up to 15,000 lbs | Up to 5,500 lbs |

| Training Required | Certified forklift training | On-the-job training |

| Typical Tasks | Lifting, stacking, moving heavy pallets | Transporting pallets within short distances |

| Work Environment | Indoor and outdoor, varying terrain | Mostly indoor, flat surfaces |

| Safety Risks | High (tip-over, collisions) | Moderate (strains, collisions) |

| Speed & Efficiency | Faster for heavy loads and long distances | Slower, best for light loads and short distances |

| Cost of Equipment | High (purchase and maintenance) | Low to moderate |

Overview of Roles: Forklift Driver vs Pallet Jack Operator

Forklift drivers operate powered industrial trucks to lift, move, and stack heavy pallets, often handling higher load capacities and navigating complex warehouse layouts, ensuring efficient material flow. Pallet jack operators manage manual or electric pallet jacks, focusing on moving palletized goods within short distances and tighter spaces, prioritizing speed and precision for order picking and staging. Both roles require safety awareness and equipment proficiency, but forklift drivers generally handle larger loads and require specialized certifications compared to pallet jack operators.

Core Responsibilities and Daily Tasks

Forklift drivers are responsible for safely operating forklifts to lift, move, and stack heavy pallets and materials within warehouses, ensuring accurate placement and inventory management. Pallet jack operators primarily handle manual or electric pallet jacks to transport lighter loads over short distances, focusing on loading, unloading, and organizing pallets on warehouse floors. Both roles require attention to safety protocols, equipment maintenance, and efficient material handling to support smooth warehouse operations.

Required Skills and Qualifications

Forklift drivers must possess a valid forklift certification, strong spatial awareness, and the ability to operate heavy machinery safely in dynamic warehouse environments. Pallet jack operators require proficiency in maneuvering manual or electric pallet jacks, basic inventory management skills, and physical stamina for lifting and transporting goods efficiently. Both roles demand attention to safety protocols, effective communication, and adherence to warehouse operational guidelines.

Safety Protocols and Compliance Standards

Forklift drivers and pallet jack operators must adhere to distinct safety protocols and compliance standards to minimize workplace accidents; forklift operators require OSHA certification and must complete rigorous training in load handling, vehicle operation, and hazard recognition. Pallet jack operators follow less intensive but specific safety guidelines focusing on load stability, pedestrian awareness, and proper manual maneuvering techniques. Both roles demand strict compliance with company policies and federal regulations to ensure safe material handling and injury prevention in warehousing environments.

Equipment Operation Differences

Forklift drivers operate powered industrial trucks capable of lifting heavier loads and reaching higher shelves, making them essential for handling bulkier items in warehouses. Pallet jack operators use manual or electric pallet jacks designed primarily for moving pallets short distances with lower weight capacity. Equipment operation differs as forklifts require specialized training and certification due to their complexity and safety risks, while pallet jacks have simpler controls and are more suited for basic, ground-level transport tasks.

Training and Certification Requirements

Forklift drivers typically require specialized training programs and certification that comply with Occupational Safety and Health Administration (OSHA) standards, ensuring safe operation of powered industrial trucks. Pallet jack operators often need less formal training, focusing on manual or electric pallet jack handling, with certification requirements varying by employer and local regulations. Proper training for both roles emphasizes safety protocols, equipment handling, and workplace hazard awareness to prevent accidents in warehouse environments.

Productivity and Efficiency Comparison

Forklift drivers typically achieve higher productivity by handling heavier loads and accessing elevated storage racks faster than pallet jack operators. Pallet jack operators excel in navigating tight spaces and performing quick, short-distance moves, enhancing operational efficiency in congested warehouse aisles. Choosing between forklift drivers and pallet jack operators depends on specific warehouse layout and workload demands to optimize overall efficiency.

Physical Demands and Work Environment

Forklift drivers face higher physical demands due to operating large machinery that requires precise control and constant alertness in often noisy, busy warehouse environments. Pallet jack operators work in similar settings but engage in more manual exertion, frequently pushing or pulling heavy loads over various surfaces. Both roles require strong spatial awareness and stamina to navigate confined spaces and maintain safety standards amid dynamic warehouse operations.

Career Advancement Opportunities

Forklift drivers often have broader career advancement opportunities due to their ability to operate various heavy machinery, which can lead to supervisory roles or equipment maintenance positions. Pallet jack operators typically focus on entry-level material handling tasks, with fewer chances for rapid promotion unless they gain additional certifications or skills. Training in forklift operation and safety compliance significantly enhances job mobility and potential for higher wages within warehousing careers.

Wage and Benefits Analysis

Forklift drivers typically earn higher wages than pallet jack operators, with average hourly rates ranging from $18 to $25 compared to $12 to $18 for pallet jack operators, reflecting the greater skill and certification required. Benefits packages for forklift drivers often include comprehensive health insurance, retirement plans, and paid training programs due to the higher responsibility and safety requirements involved. Employers may offer fewer benefits to pallet jack operators, prioritizing cost-efficiency in lower-skilled roles while focusing on basic healthcare and limited paid time off.

Forklift Driver vs Pallet Jack Operator Infographic

jobdiv.com

jobdiv.com