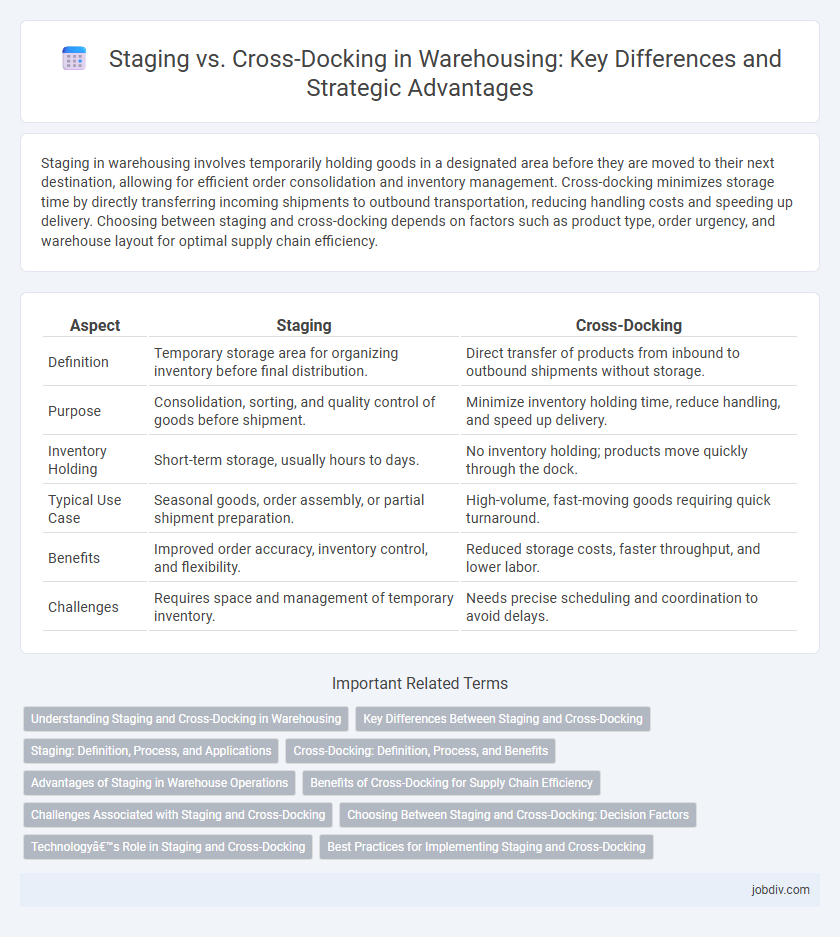

Staging in warehousing involves temporarily holding goods in a designated area before they are moved to their next destination, allowing for efficient order consolidation and inventory management. Cross-docking minimizes storage time by directly transferring incoming shipments to outbound transportation, reducing handling costs and speeding up delivery. Choosing between staging and cross-docking depends on factors such as product type, order urgency, and warehouse layout for optimal supply chain efficiency.

Table of Comparison

| Aspect | Staging | Cross-Docking |

|---|---|---|

| Definition | Temporary storage area for organizing inventory before final distribution. | Direct transfer of products from inbound to outbound shipments without storage. |

| Purpose | Consolidation, sorting, and quality control of goods before shipment. | Minimize inventory holding time, reduce handling, and speed up delivery. |

| Inventory Holding | Short-term storage, usually hours to days. | No inventory holding; products move quickly through the dock. |

| Typical Use Case | Seasonal goods, order assembly, or partial shipment preparation. | High-volume, fast-moving goods requiring quick turnaround. |

| Benefits | Improved order accuracy, inventory control, and flexibility. | Reduced storage costs, faster throughput, and lower labor. |

| Challenges | Requires space and management of temporary inventory. | Needs precise scheduling and coordination to avoid delays. |

Understanding Staging and Cross-Docking in Warehousing

Staging in warehousing involves temporarily holding goods in a designated area to prepare for further processing or shipment, enabling efficient sorting, packing, and quality checks. Cross-docking eliminates storage time by directly transferring incoming products to outbound transportation, minimizing inventory holding costs and reducing handling time. Understanding the differences between staging and cross-docking helps optimize warehouse flow, improve inventory turnover, and enhance supply chain responsiveness.

Key Differences Between Staging and Cross-Docking

Staging in warehousing involves temporarily storing goods in a designated area before shipping, allowing for quality checks and order consolidation, whereas cross-docking minimizes storage time by directly transferring products from inbound to outbound transportation. Staging enhances inventory accuracy and flexibility, while cross-docking optimizes supply chain efficiency by reducing handling and inventory carrying costs. Key differences include the time products spend in the warehouse and the level of handling required before dispatch.

Staging: Definition, Process, and Applications

Staging in warehousing refers to the process of temporarily placing goods in a designated area before they are moved to their final destination, allowing for quality checks and order consolidation. This process optimizes inventory flow by organizing products for efficient packing, shipment, or further processing. Common applications of staging include preparing orders for distribution centers, facilitating assembly line production, and managing seasonal inventory surges.

Cross-Docking: Definition, Process, and Benefits

Cross-docking is a logistics strategy that involves unloading inbound shipments directly onto outbound transportation with minimal or no storage time, enhancing supply chain efficiency. The process includes receiving goods, sorting or consolidating them based on destination, and immediately loading them onto outbound trucks, reducing handling and storage costs. Benefits of cross-docking include faster delivery times, reduced inventory holding, lower warehousing expenses, and improved product flow throughout the distribution network.

Advantages of Staging in Warehouse Operations

Staging in warehouse operations enhances inventory management by allowing temporary storage and sorting of products before final dispatch, reducing errors and improving order accuracy. It facilitates efficient labor allocation and workflow planning, promoting smoother handling of peak demand periods. The process supports quality control checks and product consolidation, leading to higher customer satisfaction and reduced return rates.

Benefits of Cross-Docking for Supply Chain Efficiency

Cross-docking reduces inventory holding costs by minimizing storage time, enabling faster product flow from suppliers to customers. This streamlined process improves order fulfillment speed and enhances supply chain responsiveness, leading to increased customer satisfaction. Efficient use of cross-docking facilities also lowers transportation expenses by consolidating shipments and reducing handling requirements.

Challenges Associated with Staging and Cross-Docking

Staging in warehousing faces challenges such as increased storage costs, the risk of inventory damage due to prolonged handling, and potential delays in order fulfillment caused by congestion in staging areas. Cross-docking presents difficulties including the need for precise synchronization between inbound and outbound shipments, dependency on accurate real-time data to prevent misrouting, and limited flexibility for accommodating unexpected demand fluctuations. Both methods require sophisticated warehouse management systems (WMS) and skilled labor to optimize operational efficiency and overcome logistical complexities.

Choosing Between Staging and Cross-Docking: Decision Factors

Choosing between staging and cross-docking depends on factors such as inventory turnover, order complexity, and space availability. Staging is optimal for managing high SKU variety and buffer stock, while cross-docking suits fast-moving products with minimal handling time. Operational efficiency improves by aligning the method with demand patterns and supply chain speed requirements.

Technology’s Role in Staging and Cross-Docking

Advanced warehouse management systems (WMS) and real-time tracking technologies are pivotal in optimizing both staging and cross-docking processes, ensuring precise inventory control and expedited order fulfillment. Automated sorting systems, RFID tagging, and AI-powered analytics enhance accuracy and efficiency by minimizing manual handling and predicting demand patterns. Integration of IoT devices facilitates seamless communication between inbound and outbound logistics, reducing lead times and improving overall supply chain responsiveness.

Best Practices for Implementing Staging and Cross-Docking

Implementing staging involves organizing inbound goods in designated areas to facilitate efficient quality checks and sorting before storage, ensuring inventory accuracy and reducing handling errors. Cross-docking requires synchronized scheduling and real-time communication between suppliers and warehouse teams to minimize storage time and expedite direct transfers from receiving to shipping docks. Leveraging warehouse management systems (WMS) and advanced barcode scanning technology enhances visibility, accuracy, and coordination in both processes for optimal operational efficiency.

Staging vs Cross-Docking Infographic

jobdiv.com

jobdiv.com