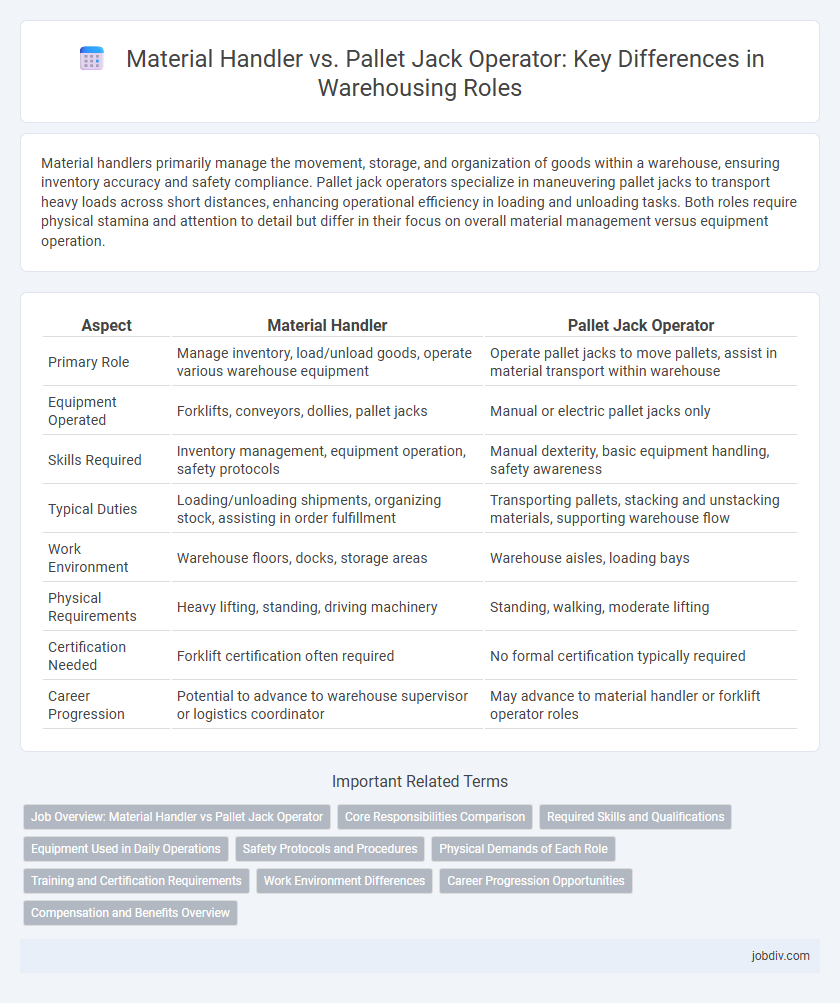

Material handlers primarily manage the movement, storage, and organization of goods within a warehouse, ensuring inventory accuracy and safety compliance. Pallet jack operators specialize in maneuvering pallet jacks to transport heavy loads across short distances, enhancing operational efficiency in loading and unloading tasks. Both roles require physical stamina and attention to detail but differ in their focus on overall material management versus equipment operation.

Table of Comparison

| Aspect | Material Handler | Pallet Jack Operator |

|---|---|---|

| Primary Role | Manage inventory, load/unload goods, operate various warehouse equipment | Operate pallet jacks to move pallets, assist in material transport within warehouse |

| Equipment Operated | Forklifts, conveyors, dollies, pallet jacks | Manual or electric pallet jacks only |

| Skills Required | Inventory management, equipment operation, safety protocols | Manual dexterity, basic equipment handling, safety awareness |

| Typical Duties | Loading/unloading shipments, organizing stock, assisting in order fulfillment | Transporting pallets, stacking and unstacking materials, supporting warehouse flow |

| Work Environment | Warehouse floors, docks, storage areas | Warehouse aisles, loading bays |

| Physical Requirements | Heavy lifting, standing, driving machinery | Standing, walking, moderate lifting |

| Certification Needed | Forklift certification often required | No formal certification typically required |

| Career Progression | Potential to advance to warehouse supervisor or logistics coordinator | May advance to material handler or forklift operator roles |

Job Overview: Material Handler vs Pallet Jack Operator

Material Handler roles involve managing inventory, loading and unloading materials, and ensuring accurate stock placement using various equipment to support warehouse operations. Pallet Jack Operators primarily operate manual or electric pallet jacks to move pallets within warehouses, focusing on the efficient transportation of goods to designated locations. Both positions require physical stamina and attention to safety protocols but differ in scope, with Material Handlers often performing broader material management tasks compared to the more specialized equipment operation by Pallet Jack Operators.

Core Responsibilities Comparison

Material Handlers primarily manage inventory movement, including loading, unloading, and organizing products within the warehouse, ensuring accurate stock levels and proper storage. Pallet Jack Operators specialize in maneuvering pallet jacks to transport heavy pallets efficiently, facilitating swift order fulfillment and maintaining workflow continuity. Both roles require attention to safety protocols and teamwork but differ in their operational focus, with Material Handlers overseeing broad material management and Pallet Jack Operators concentrating on equipment-based pallet transport.

Required Skills and Qualifications

Material Handlers require strong physical stamina, proficiency in inventory management software, and knowledge of safe lifting techniques to efficiently move and organize goods in a warehouse. Pallet Jack Operators must possess skillful operation of electric or manual pallet jacks, attention to detail for load stability, and certification in equipment handling to ensure safe transportation of pallets. Both roles demand excellent hand-eye coordination, basic math skills for inventory tracking, and adherence to workplace safety regulations.

Equipment Used in Daily Operations

Material Handlers operate a variety of equipment including forklifts, pallet jacks, conveyor systems, and hand trucks, enabling efficient movement, loading, and unloading of materials within warehouses. Pallet Jack Operators primarily use manual or electric pallet jacks designed for lifting and transporting palletized goods over short distances with precision and ease. The distinction in equipment highlights the broader scope of Material Handler duties compared to the more specialized focus of Pallet Jack Operators.

Safety Protocols and Procedures

Material Handlers and Pallet Jack Operators adhere strictly to safety protocols to minimize workplace accidents and ensure efficient operations. Material Handlers prioritize proper lifting techniques and the use of personal protective equipment (PPE) to prevent musculoskeletal injuries, while Pallet Jack Operators focus on safe equipment operation, including speed control and clear pathway navigation to avoid collisions. Both roles require continuous safety training and compliance with OSHA regulations to maintain a secure warehouse environment.

Physical Demands of Each Role

Material Handlers often face rigorous physical demands including lifting heavy items up to 50 pounds, frequent bending, and prolonged standing or walking to move inventory throughout the warehouse. Pallet Jack Operators must skillfully maneuver pallet jacks weighing up to 2,500 pounds, requiring significant upper body strength and agility to navigate tight spaces while maintaining control of heavy loads. Both roles demand endurance and proper ergonomic practices to prevent injuries from repetitive motions and heavy lifting in a fast-paced warehousing environment.

Training and Certification Requirements

Material handlers typically require comprehensive training that includes safety protocols, inventory management, and operation of various equipment, often culminating in certification programs tailored to warehouse environments. Pallet jack operators must complete specific certification courses emphasizing safe handling, maneuvering techniques, and load capacity awareness to comply with OSHA standards. Both roles benefit from hands-on instruction and periodic recertification to ensure adherence to industry safety regulations and efficient warehouse operations.

Work Environment Differences

Material Handlers typically work in diverse warehouse settings, handling a wide range of materials, often involving heavier lifting and frequent movement across the facility. Pallet Jack Operators concentrate on maneuvering pallets within aisles and loading docks, operating specialized equipment in tighter, more controlled spaces. The work environment for Material Handlers requires adaptability to various tasks and conditions, while Pallet Jack Operators focus on precision within structured pathways and equipment operation protocols.

Career Progression Opportunities

Material Handlers often have broader career progression opportunities due to their involvement in multiple warehouse functions such as inventory management, shipping, and receiving. Pallet Jack Operators typically specialize in operating pallet jacks for loading and unloading tasks, which can limit advancement unless they acquire additional skills or certifications. Expanding expertise in equipment operation and warehouse technology enhances promotion prospects for both roles.

Compensation and Benefits Overview

Material Handlers typically earn an average hourly wage ranging from $14 to $20, while Pallet Jack Operators usually receive between $13 and $18 per hour, reflecting slight variations based on experience and location. Benefits for both roles often include health insurance, paid time off, and retirement plans, with some employers offering performance bonuses and overtime pay. Material Handlers may have access to broader skill development opportunities and higher overtime potential, influencing overall compensation packages.

Material Handler vs Pallet Jack Operator Infographic

jobdiv.com

jobdiv.com