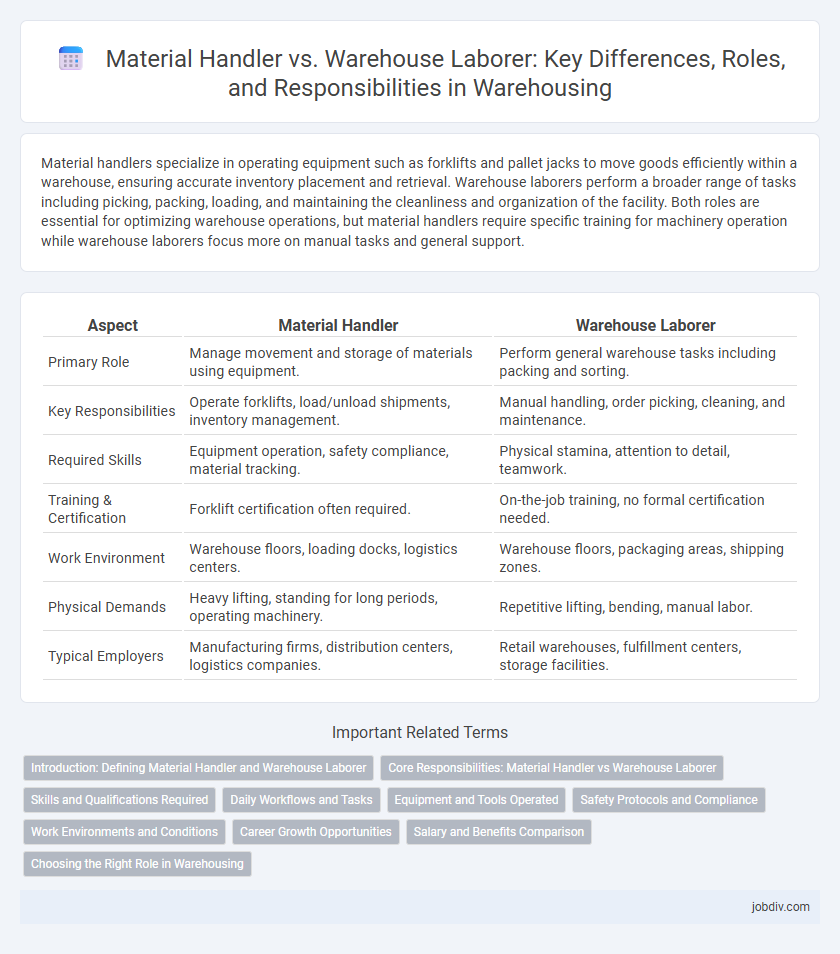

Material handlers specialize in operating equipment such as forklifts and pallet jacks to move goods efficiently within a warehouse, ensuring accurate inventory placement and retrieval. Warehouse laborers perform a broader range of tasks including picking, packing, loading, and maintaining the cleanliness and organization of the facility. Both roles are essential for optimizing warehouse operations, but material handlers require specific training for machinery operation while warehouse laborers focus more on manual tasks and general support.

Table of Comparison

| Aspect | Material Handler | Warehouse Laborer |

|---|---|---|

| Primary Role | Manage movement and storage of materials using equipment. | Perform general warehouse tasks including packing and sorting. |

| Key Responsibilities | Operate forklifts, load/unload shipments, inventory management. | Manual handling, order picking, cleaning, and maintenance. |

| Required Skills | Equipment operation, safety compliance, material tracking. | Physical stamina, attention to detail, teamwork. |

| Training & Certification | Forklift certification often required. | On-the-job training, no formal certification needed. |

| Work Environment | Warehouse floors, loading docks, logistics centers. | Warehouse floors, packaging areas, shipping zones. |

| Physical Demands | Heavy lifting, standing for long periods, operating machinery. | Repetitive lifting, bending, manual labor. |

| Typical Employers | Manufacturing firms, distribution centers, logistics companies. | Retail warehouses, fulfillment centers, storage facilities. |

Introduction: Defining Material Handler and Warehouse Laborer

Material Handlers manage the organization, movement, and storage of goods within a warehouse, often using machinery like forklifts and pallet jacks to ensure efficient inventory control. Warehouse Laborers perform essential physical tasks such as loading, unloading, packing, and maintaining cleanliness, supporting overall warehouse operations through manual labor. Both roles are integral to inventory management, but Material Handlers typically require specialized equipment skills, while Warehouse Laborers focus on foundational operational support.

Core Responsibilities: Material Handler vs Warehouse Laborer

Material handlers primarily manage inventory movement using equipment like forklifts, ensuring accurate receipt, storage, and shipment of goods within the warehouse. Warehouse laborers focus on general tasks such as loading, unloading, packing, and maintaining a clean and organized work environment to support operational efficiency. Both roles are critical for seamless warehouse operations but differ in the specificity of their responsibilities and required skills.

Skills and Qualifications Required

Material handlers require skills in operating forklifts, using inventory management software, and understanding shipping protocols. Warehouse laborers need physical stamina, basic equipment operation abilities, and experience with order picking and packing. Both roles demand attention to detail, time management, and adherence to safety regulations to ensure efficient warehouse operations.

Daily Workflows and Tasks

Material Handlers primarily manage the movement, loading, and unloading of inventory using equipment such as forklifts and pallet jacks, ensuring accurate placement and tracking within the warehouse. Warehouse Laborers perform a variety of manual tasks including picking, packing, sorting, and stocking goods, maintaining cleanliness and organization in storage areas. Both roles are critical to streamlining daily workflows and maintaining efficient inventory turnover in warehouse operations.

Equipment and Tools Operated

Material Handlers typically operate specialized equipment such as forklifts, pallet jacks, and conveyor systems to efficiently move heavy loads within warehouses. Warehouse Laborers often use manual tools like hand trucks, box cutters, and basic lifting equipment to assist in packing, sorting, and organizing inventory. Both roles require proficiency with safety protocols related to their respective tools and machinery to maintain operational efficiency.

Safety Protocols and Compliance

Material handlers and warehouse laborers both play critical roles in warehousing operations, with safety protocols and compliance being paramount in their daily tasks. Material handlers often operate heavy machinery such as forklifts, requiring strict adherence to OSHA standards and regular safety training to prevent workplace injuries. Warehouse laborers focus on manual tasks including lifting and sorting, necessitating consistent use of personal protective equipment (PPE) and compliance with ergonomic guidelines to minimize strain and accidents.

Work Environments and Conditions

Material handlers typically work in environments requiring the operation of machinery such as forklifts and pallet jacks, often in warehouses with controlled temperatures and strict safety protocols. Warehouse laborers perform more physically demanding tasks like loading, unloading, and sorting, frequently exposed to varying temperature conditions and manual handling risks. Both roles require adherence to safety standards but differ in physical strain and machinery interaction within warehouse settings.

Career Growth Opportunities

Material Handlers often have clearer career growth pathways due to specialized training in equipment operation and inventory management, leading to supervisory or logistics roles. Warehouse Laborers typically start with general tasks but can advance by gaining skills in safety protocols, technology use, and team leadership. Both roles benefit from certifications and experience that open doors to higher-paying positions within warehouse management and operations.

Salary and Benefits Comparison

Material Handlers typically earn a higher average salary than Warehouse Laborers, with hourly wages ranging from $15 to $22 compared to $12 to $18 for Laborers. Benefits for Material Handlers often include comprehensive health insurance, retirement plans, and performance bonuses, while Warehouse Laborers usually receive basic benefits such as paid time off and limited health coverage. The variation in compensation reflects the differing skill requirements and responsibilities between the two roles in warehousing operations.

Choosing the Right Role in Warehousing

Material handlers specialize in the efficient movement and storage of goods using equipment like forklifts and pallet jacks, ensuring accurate inventory management and timely order fulfillment. Warehouse laborers perform diverse physical tasks such as loading, unloading, packing, and maintaining warehouse cleanliness to support overall operational flow. Choosing the right role depends on skill set, physical capability, and preference for specialized equipment operation versus general warehouse duties, aligning workforce strengths with organizational logistics needs.

Material Handler vs Warehouse Laborer Infographic

jobdiv.com

jobdiv.com