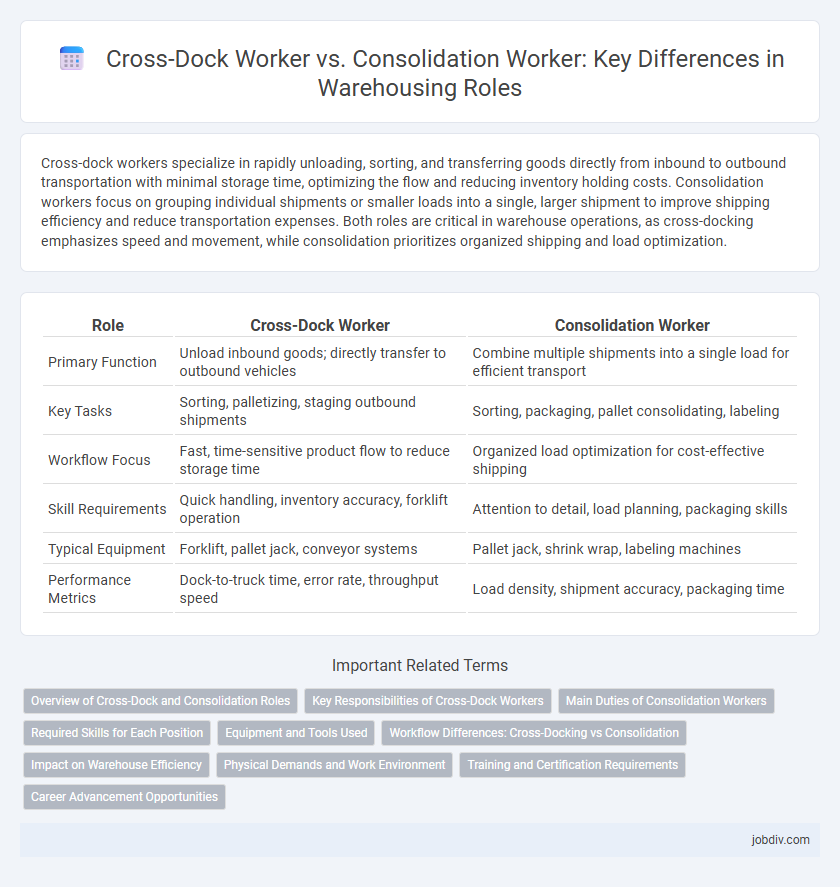

Cross-dock workers specialize in rapidly unloading, sorting, and transferring goods directly from inbound to outbound transportation with minimal storage time, optimizing the flow and reducing inventory holding costs. Consolidation workers focus on grouping individual shipments or smaller loads into a single, larger shipment to improve shipping efficiency and reduce transportation expenses. Both roles are critical in warehouse operations, as cross-docking emphasizes speed and movement, while consolidation prioritizes organized shipping and load optimization.

Table of Comparison

| Role | Cross-Dock Worker | Consolidation Worker |

|---|---|---|

| Primary Function | Unload inbound goods; directly transfer to outbound vehicles | Combine multiple shipments into a single load for efficient transport |

| Key Tasks | Sorting, palletizing, staging outbound shipments | Sorting, packaging, pallet consolidating, labeling |

| Workflow Focus | Fast, time-sensitive product flow to reduce storage time | Organized load optimization for cost-effective shipping |

| Skill Requirements | Quick handling, inventory accuracy, forklift operation | Attention to detail, load planning, packaging skills |

| Typical Equipment | Forklift, pallet jack, conveyor systems | Pallet jack, shrink wrap, labeling machines |

| Performance Metrics | Dock-to-truck time, error rate, throughput speed | Load density, shipment accuracy, packaging time |

Overview of Cross-Dock and Consolidation Roles

Cross-dock workers manage the rapid transfer of goods from incoming to outgoing transportation, minimizing storage time and optimizing supply chain efficiency. Consolidation workers focus on combining multiple shipments into a single load for delivery, improving inventory management and reducing transportation costs. Both roles are essential in warehousing operations to enhance throughput, reduce handling times, and streamline logistics processes.

Key Responsibilities of Cross-Dock Workers

Cross-dock workers primarily manage the rapid transfer of goods from inbound to outbound shipping, ensuring minimal storage time and efficient flow of materials. They are responsible for sorting, scanning, and loading shipments directly onto outbound trucks, maintaining accuracy and speed to meet tight delivery schedules. Their role demands strong coordination with warehouse logistics and real-time inventory management systems to optimize cross-docking efficiency.

Main Duties of Consolidation Workers

Consolidation workers organize and combine shipments from multiple sources into a single load for efficient transportation, ensuring accurate sorting and packaging according to delivery schedules. They verify product quantities and quality, prepare consolidation manifests, and coordinate with drivers and warehouse teams to optimize loading procedures. These workers play a critical role in maintaining inventory accuracy and streamlining the distribution process within the supply chain.

Required Skills for Each Position

Cross-dock workers require strong organizational skills, quick decision-making abilities, and proficiency in operating material handling equipment to efficiently transfer goods between inbound and outbound shipments. Consolidation workers must excel in inventory management, attention to detail, and teamwork to accurately combine multiple shipments into a single load for distribution. Both roles demand physical stamina and familiarity with warehouse management systems (WMS) to ensure seamless workflow and inventory accuracy.

Equipment and Tools Used

Cross-dock workers primarily utilize conveyor belts, pallet jacks, forklifts, and handheld barcode scanners to facilitate rapid unloading and immediate sorting of goods for outbound shipment. Consolidation workers depend on pallet stretch wraps, shrink tunnels, forklifts, and weighing scales to combine multiple shipments into a single consolidated load for efficient transport. Both roles leverage warehouse management system (WMS) devices for inventory tracking and communication, but cross-dock workers emphasize speed-oriented tools while consolidation workers focus on packaging and load optimization equipment.

Workflow Differences: Cross-Docking vs Consolidation

Cross-dock workers rapidly transfer inbound goods directly to outbound transportation, minimizing storage time and enhancing throughput efficiency. Consolidation workers organize and combine multiple smaller shipments into larger, coordinated loads, optimizing space utilization and ensuring shipment accuracy. The workflow in cross-docking emphasizes speed and immediate sorting, while consolidation prioritizes strategic assembly and load planning.

Impact on Warehouse Efficiency

Cross-dock workers streamline warehouse operations by rapidly unloading incoming shipments and sorting products directly for outbound trucks, significantly reducing storage time and improving throughput. Consolidation workers enhance efficiency by grouping shipments from multiple sources into single outbound loads, optimizing space utilization and minimizing transportation costs. Together, these specialized roles drive faster inventory turnover and reduce operational bottlenecks, boosting overall warehouse productivity.

Physical Demands and Work Environment

Cross-dock workers face intense physical demands, including frequent lifting and moving of heavy pallets in fast-paced, time-sensitive environments designed for quick unloading and loading of goods. Consolidation workers engage in repetitive manual handling, stacking, and organizing shipments, often in warehouse zones focused on assembling orders for final distribution, requiring sustained physical effort in confined spaces. Both roles demand endurance and strength, but cross-dock duties emphasize speed and rapid pallet movement, while consolidation emphasizes accuracy and systematic organization under consistent physical strain.

Training and Certification Requirements

Cross-dock workers require training in rapid sorting techniques, safety protocols, and basic forklift operation, often supported by certifications like OSHA Forklift Operator and handling hazardous materials. Consolidation workers need specialized training in inventory management systems, load optimization, and quality control, with certifications in warehouse management systems (WMS) and lean supply chain practices. Both roles emphasize hands-on experience and continuous skill development to ensure efficient warehouse operations and compliance with industry standards.

Career Advancement Opportunities

Cross-dock workers quickly transfer incoming shipments to outbound trucks, gaining skills in rapid inventory handling and logistics coordination essential for supervisory roles in fast-paced warehouse environments. Consolidation workers specialize in combining multiple shipments into single loads, developing expertise in load optimization and inventory accuracy valuable for roles in warehouse management and operations planning. Both positions offer career advancement through skill development in logistics, but consolidation work provides more opportunities to progress into strategic planning and inventory control roles.

Cross-Dock Worker vs Consolidation Worker Infographic

jobdiv.com

jobdiv.com