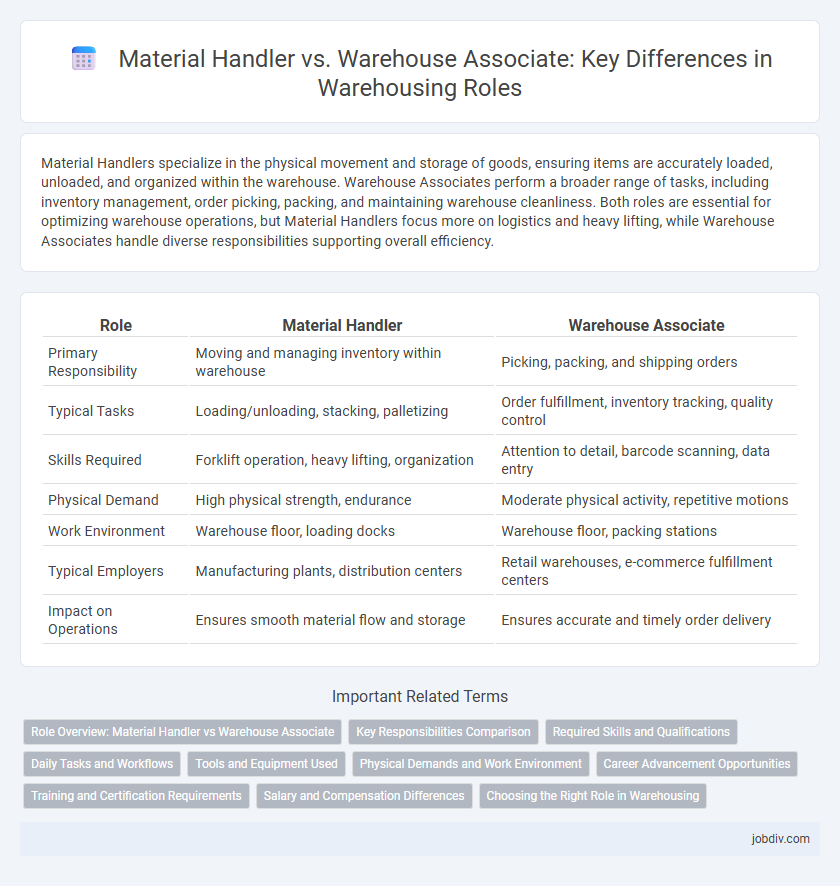

Material Handlers specialize in the physical movement and storage of goods, ensuring items are accurately loaded, unloaded, and organized within the warehouse. Warehouse Associates perform a broader range of tasks, including inventory management, order picking, packing, and maintaining warehouse cleanliness. Both roles are essential for optimizing warehouse operations, but Material Handlers focus more on logistics and heavy lifting, while Warehouse Associates handle diverse responsibilities supporting overall efficiency.

Table of Comparison

| Role | Material Handler | Warehouse Associate |

|---|---|---|

| Primary Responsibility | Moving and managing inventory within warehouse | Picking, packing, and shipping orders |

| Typical Tasks | Loading/unloading, stacking, palletizing | Order fulfillment, inventory tracking, quality control |

| Skills Required | Forklift operation, heavy lifting, organization | Attention to detail, barcode scanning, data entry |

| Physical Demand | High physical strength, endurance | Moderate physical activity, repetitive motions |

| Work Environment | Warehouse floor, loading docks | Warehouse floor, packing stations |

| Typical Employers | Manufacturing plants, distribution centers | Retail warehouses, e-commerce fulfillment centers |

| Impact on Operations | Ensures smooth material flow and storage | Ensures accurate and timely order delivery |

Role Overview: Material Handler vs Warehouse Associate

Material Handlers primarily focus on the physical movement, loading, and unloading of goods within the warehouse, ensuring accurate inventory placement and minimizing damage during transit. Warehouse Associates perform a broader range of tasks including inventory management, order picking, packing, and operating warehouse equipment. Understanding the distinct roles helps optimize warehouse efficiency and align job responsibilities with operational needs.

Key Responsibilities Comparison

Material Handlers primarily focus on moving, loading, and unloading inventory using forklifts and pallet jacks, ensuring accurate placement in storage areas. Warehouse Associates manage a broader range of tasks including inventory tracking, order picking, packing, and quality inspections to support efficient warehouse operations. Both roles require strong attention to detail and physical stamina but differ in their emphasis on specific operational duties within warehousing logistics.

Required Skills and Qualifications

Material Handlers require expertise in operating forklifts, pallet jacks, and inventory management software, emphasizing physical stamina and attention to detail. Warehouse Associates must possess skills in order picking, packing, and shipping with proficiency in basic computer skills and effective communication. Both roles demand knowledge of safety protocols, organizational abilities, and the capacity to work in fast-paced environments.

Daily Tasks and Workflows

Material Handlers primarily focus on the movement, loading, and unloading of goods within the warehouse, ensuring efficient inventory transport using equipment like forklifts and pallet jacks. Warehouse Associates handle a wider scope of daily tasks including order picking, packing, inventory management, and quality control to maintain accurate stock levels and prepare shipments. Both roles require adherence to safety protocols and collaboration with logistics teams to optimize workflow and meet operational deadlines.

Tools and Equipment Used

Material Handlers frequently operate forklifts, pallet jacks, and conveyor systems to move heavy goods efficiently within warehouses. Warehouse Associates commonly use barcode scanners, order pickers, and packaging tools to manage inventory accuracy and prepare shipments. Both roles rely on digital inventory management software and safety gear such as gloves and steel-toe boots to ensure operational safety and productivity.

Physical Demands and Work Environment

Material Handlers typically engage in more physically demanding tasks such as lifting, moving heavy pallets, and operating forklifts in large warehouse spaces. Warehouse Associates often perform a broader range of duties including picking, packing, and inventory management, which may involve less intense physical strain but sustained periods of standing and walking. Both roles require adapting to fast-paced environments with varying temperatures, noise levels, and safety protocols essential for maintaining operational efficiency.

Career Advancement Opportunities

Material Handlers often begin with basic logistics tasks and can advance into specialized roles such as inventory control or equipment operation, leveraging their hands-on experience. Warehouse Associates typically have broader responsibilities, including order fulfillment and quality assurance, providing a diverse skill set that can lead to supervisory or management positions. Career advancement in warehousing favors individuals who gain expertise in warehouse management systems, safety protocols, and cross-functional team collaboration.

Training and Certification Requirements

Material Handlers typically require basic on-the-job training in equipment operation and safety protocols, while Warehouse Associates often need more comprehensive certification such as OSHA safety training and forklift operator licenses. Advanced roles in warehousing demand familiarity with inventory management systems, for which Warehouse Associates are more frequently certified. Employers prioritize candidates with formal certifications to minimize workplace accidents and enhance operational efficiency.

Salary and Compensation Differences

Material handlers typically earn a salary ranging from $30,000 to $40,000 annually, reflecting their specialized role in managing inventory movement and equipment operation. Warehouse associates generally receive slightly lower compensation, averaging between $28,000 and $38,000 per year, due to broader responsibilities such as order picking, packing, and shipping. Salary variations depend on factors like location, experience, and company size, with material handlers often benefiting from higher pay due to required technical skills and certifications.

Choosing the Right Role in Warehousing

Choosing the right role in warehousing depends on specific job responsibilities and required skills; material handlers specialize in moving, loading, and unloading goods using equipment like forklifts, while warehouse associates perform broader tasks including inventory management, order picking, and packaging. Evaluating factors such as physical demands, skillsets in equipment operation, and familiarity with warehouse management systems helps in deciding between these roles. Aligning career goals with the operational focus and growth opportunities of each position ensures optimal job satisfaction and efficiency in warehouse logistics.

Material Handler vs Warehouse Associate Infographic

jobdiv.com

jobdiv.com