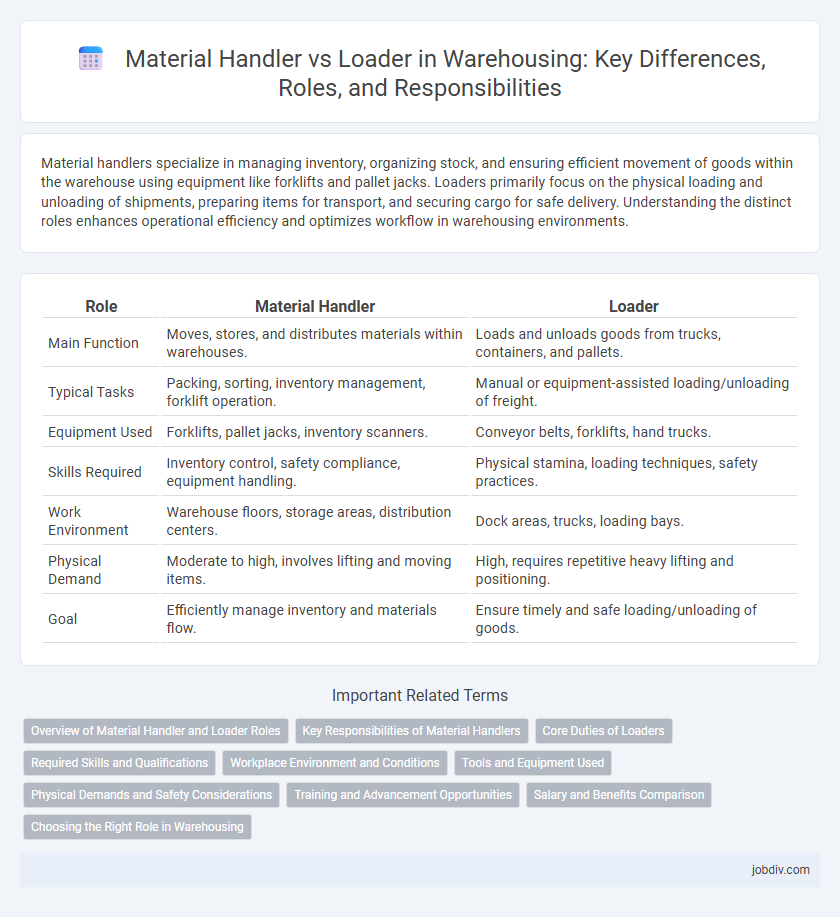

Material handlers specialize in managing inventory, organizing stock, and ensuring efficient movement of goods within the warehouse using equipment like forklifts and pallet jacks. Loaders primarily focus on the physical loading and unloading of shipments, preparing items for transport, and securing cargo for safe delivery. Understanding the distinct roles enhances operational efficiency and optimizes workflow in warehousing environments.

Table of Comparison

| Role | Material Handler | Loader |

|---|---|---|

| Main Function | Moves, stores, and distributes materials within warehouses. | Loads and unloads goods from trucks, containers, and pallets. |

| Typical Tasks | Packing, sorting, inventory management, forklift operation. | Manual or equipment-assisted loading/unloading of freight. |

| Equipment Used | Forklifts, pallet jacks, inventory scanners. | Conveyor belts, forklifts, hand trucks. |

| Skills Required | Inventory control, safety compliance, equipment handling. | Physical stamina, loading techniques, safety practices. |

| Work Environment | Warehouse floors, storage areas, distribution centers. | Dock areas, trucks, loading bays. |

| Physical Demand | Moderate to high, involves lifting and moving items. | High, requires repetitive heavy lifting and positioning. |

| Goal | Efficiently manage inventory and materials flow. | Ensure timely and safe loading/unloading of goods. |

Overview of Material Handler and Loader Roles

Material handlers manage inventory movement, storage, and organization within warehouses, ensuring efficient material flow and accurate record-keeping. Loaders specialize in the physical loading and unloading of goods onto trucks, trailers, or conveyor systems, prioritizing safety and speed to optimize shipping operations. Both roles are essential for maintaining seamless supply chain logistics and warehouse productivity.

Key Responsibilities of Material Handlers

Material handlers are responsible for receiving, storing, and distributing materials within warehouses, ensuring accurate inventory management and timely order fulfillment. They operate equipment such as forklifts and pallet jacks to move products safely and efficiently while maintaining compliance with safety regulations. Their role includes verifying shipment contents, preparing materials for shipment, and assisting in inventory audits to support warehouse operations.

Core Duties of Loaders

Loaders primarily focus on the efficient and safe movement of goods by loading and unloading materials onto trucks, pallets, or conveyors in warehouses or distribution centers. Their core duties include verifying shipment contents, securing loads to prevent damage during transit, and maintaining organized staging areas to facilitate smooth operations. Loaders also operate forklifts, pallet jacks, and hand trucks to handle heavy or bulky items, ensuring inventory accuracy and timely dispatch.

Required Skills and Qualifications

Material handlers require strong organizational skills, inventory management knowledge, and proficiency in operating forklifts and pallet jacks, along with basic computer literacy for tracking shipments. Loaders need physical strength, stamina, and the ability to safely handle heavy and bulky items, complemented by familiarity with safety protocols and effective communication skills for coordinating with warehouse staff. Both roles demand attention to detail, adherence to safety standards, and the ability to work efficiently in fast-paced environments.

Workplace Environment and Conditions

Material handlers typically operate within organized warehouse settings, managing inventory through forklifts or pallet jacks in climate-controlled environments that prioritize safety and efficiency. Loaders frequently work in more physically demanding conditions, often outdoors or in loading docks exposed to varying weather, requiring extensive lifting, carrying, and manual handling of goods. Both roles demand adherence to safety standards, but loaders face higher risks related to environmental exposure and strenuous physical activity.

Tools and Equipment Used

Material handlers typically utilize forklifts, pallet jacks, and conveyor systems to efficiently move, store, and organize inventory within warehouses. Loaders rely heavily on loading docks, cranes, and hand trucks to transfer goods between transport vehicles and storage areas. Both roles require safety equipment such as gloves, steel-toed boots, and reflective vests to ensure operational safety.

Physical Demands and Safety Considerations

Material handlers require high physical stamina to lift, carry, and move heavy pallets and equipment frequently, often utilizing ergonomic tools to reduce strain. Loaders face intense physical demands involving repetitive bending, lifting, and securing cargo under time-sensitive conditions, increasing the risk of musculoskeletal injuries. Both roles demand strict adherence to safety protocols, including proper use of personal protective equipment (PPE) and compliance with OSHA regulations to minimize workplace accidents.

Training and Advancement Opportunities

Material handlers receive comprehensive training in inventory management, equipment operation, and safety protocols, providing a strong foundation for career advancement within warehousing. Loaders typically undergo focused training on safe and efficient loading techniques, with limited scope for skill diversification compared to material handlers. Opportunities for advancement are broader for material handlers, who can progress into supervisory roles, inventory control, and logistics coordination, while loaders often advance primarily within the physical loading and unloading domain.

Salary and Benefits Comparison

Material Handlers typically earn an average salary ranging from $30,000 to $45,000 annually, while Loaders usually have a slightly lower pay scale between $28,000 and $40,000 per year. Benefits for Material Handlers often include health insurance, retirement plans, and paid time off, with many employers offering similar packages to Loaders but with added opportunities for overtime and bonuses. Comparing both roles, Material Handlers generally receive higher compensation and more extensive benefits due to the broader scope of responsibilities in warehouse operations.

Choosing the Right Role in Warehousing

Choosing the right role in warehousing depends on specific operational needs and skill sets; Material Handlers specialize in inventory management, order picking, and ensuring accurate stock levels, while Loaders focus on the physical loading and unloading of goods for transportation. Material Handlers require proficiency in warehouse management systems (WMS) and inventory control techniques, whereas Loaders prioritize physical strength and knowledge of safe lifting practices. Aligning these roles with organizational priorities enhances efficiency in supply chain operations and reduces errors in order fulfillment.

Material Handler vs Loader Infographic

jobdiv.com

jobdiv.com