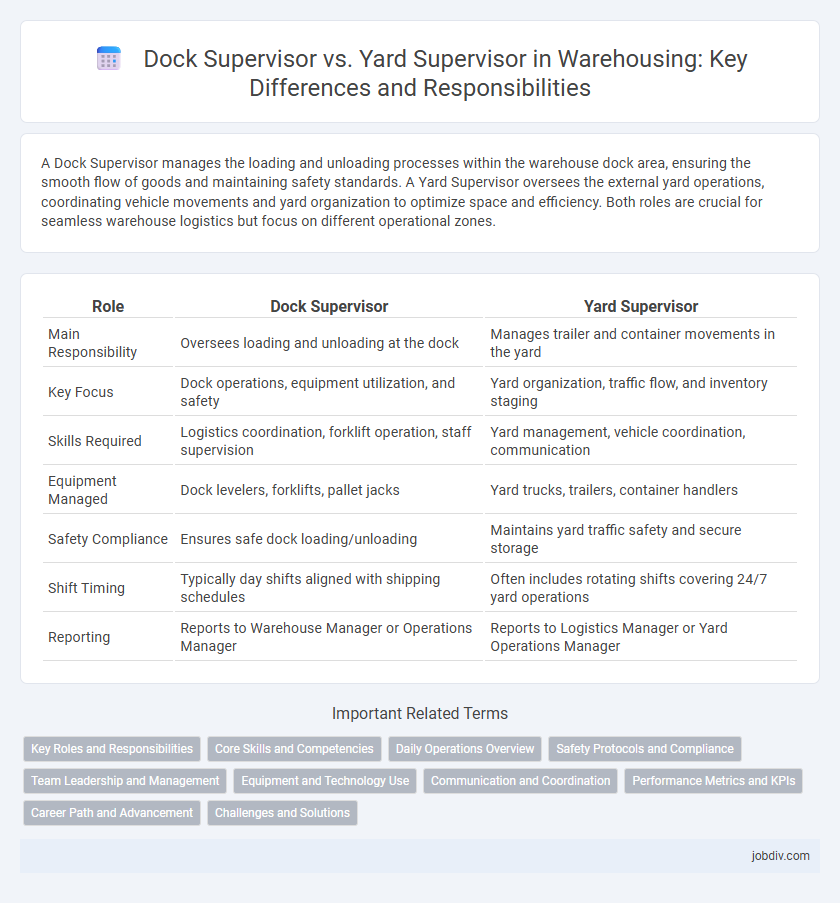

A Dock Supervisor manages the loading and unloading processes within the warehouse dock area, ensuring the smooth flow of goods and maintaining safety standards. A Yard Supervisor oversees the external yard operations, coordinating vehicle movements and yard organization to optimize space and efficiency. Both roles are crucial for seamless warehouse logistics but focus on different operational zones.

Table of Comparison

| Role | Dock Supervisor | Yard Supervisor |

|---|---|---|

| Main Responsibility | Oversees loading and unloading at the dock | Manages trailer and container movements in the yard |

| Key Focus | Dock operations, equipment utilization, and safety | Yard organization, traffic flow, and inventory staging |

| Skills Required | Logistics coordination, forklift operation, staff supervision | Yard management, vehicle coordination, communication |

| Equipment Managed | Dock levelers, forklifts, pallet jacks | Yard trucks, trailers, container handlers |

| Safety Compliance | Ensures safe dock loading/unloading | Maintains yard traffic safety and secure storage |

| Shift Timing | Typically day shifts aligned with shipping schedules | Often includes rotating shifts covering 24/7 yard operations |

| Reporting | Reports to Warehouse Manager or Operations Manager | Reports to Logistics Manager or Yard Operations Manager |

Key Roles and Responsibilities

Dock Supervisors manage inbound and outbound shipments, ensuring accurate loading and unloading while maintaining safety protocols. Yard Supervisors oversee vehicle movements and yard operations, coordinating trailers and equipment to optimize space utilization and workflow efficiency. Both roles require strong communication skills and adherence to safety standards but differ in scope, with Dock Supervisors focused on dock activities and Yard Supervisors managing outdoor yard logistics.

Core Skills and Competencies

Dock Supervisors excel in inventory control, shipment coordination, and equipment operation, ensuring seamless loading and unloading processes. Yard Supervisors demonstrate expertise in vehicle traffic management, yard organization, and safety compliance to maintain efficient outdoor logistics. Both roles require strong leadership, communication, and problem-solving skills to optimize warehouse operations and meet delivery deadlines.

Daily Operations Overview

Dock Supervisors oversee the loading and unloading of shipments, manage dock schedules, and ensure safety protocols during goods transfer. Yard Supervisors coordinate the movement and parking of trailers and trucks within the yard, optimizing space and traffic flow to prevent delays. Both roles require real-time communication to maintain seamless warehouse operations and minimize downtime.

Safety Protocols and Compliance

Dock Supervisors enforce safety protocols focused on loading dock operations, ensuring compliance with OSHA regulations concerning fall protection, equipment handling, and emergency procedures. Yard Supervisors manage safety in vehicle and equipment movement within the yard, emphasizing traffic control, hazardous material handling, and personal protective equipment usage in accordance with DOT and EPA guidelines. Both roles collaborate to maintain a comprehensive safety management system, reducing workplace accidents and regulatory infractions.

Team Leadership and Management

Dock Supervisors excel in managing loading dock operations by coordinating inbound and outbound shipments, ensuring timely and safe product handling while leading teams focused on dock efficiency. Yard Supervisors oversee yard activities, including trailer staging and vehicle movements, emphasizing spatial organization and communication with drivers to optimize yard flow and safety. Both roles demand strong leadership skills, but Dock Supervisors prioritize direct team coordination within the dock area, whereas Yard Supervisors manage broader operational logistics outside the warehouse.

Equipment and Technology Use

Dock Supervisors oversee loading dock operations using advanced conveyor systems, dock levelers, and automated barcode scanners to ensure efficient material handling and inventory accuracy. Yard Supervisors manage yard equipment such as forklifts, yard trucks, and GPS-enabled yard management systems to coordinate trailer movements and optimize space utilization. Both roles leverage technology to enhance operational workflows but differ in equipment focus, with Dock Supervisors prioritizing docking technology and Yard Supervisors concentrating on yard mobility tools.

Communication and Coordination

A Dock Supervisor manages inbound and outbound shipments, coordinating closely with warehouse staff and transportation teams to ensure timely loading and unloading. A Yard Supervisor oversees yard activities, directing vehicle movement and coordinating with dock personnel to optimize space and operational flow. Effective communication between both roles is essential to synchronize schedules, minimize delays, and enhance overall warehouse efficiency.

Performance Metrics and KPIs

Dock Supervisors primarily focus on metrics such as dock turnaround time, loading and unloading accuracy, and shipment processing speed to ensure efficient inbound and outbound logistics. Yard Supervisors emphasize KPIs like yard dwell time, equipment utilization rates, and trailer movement efficiency for optimal yard operations. Both roles rely on performance indicators such as order accuracy, safety incident frequency, and labor productivity to enhance overall warehouse throughput.

Career Path and Advancement

Dock Supervisors typically advance by gaining expertise in loading and unloading operations, inventory management, and team leadership, often progressing to roles such as Warehouse Manager or Supply Chain Coordinator. Yard Supervisors develop skills in vehicle movement, yard safety, and logistics coordination, positioning themselves for promotion to Logistics Manager or Distribution Center Supervisor. Both career paths emphasize operational efficiency and staff supervision, with opportunities for upward mobility in warehousing and supply chain management.

Challenges and Solutions

Dock Supervisors face challenges like coordinating inbound and outbound shipments efficiently while managing tight schedules and safety compliance, requiring solutions such as real-time tracking systems and streamlined communication protocols. Yard Supervisors manage the complexities of vehicle movement and storage space optimization amid fluctuating inventory levels, addressing these issues through advanced yard management software and predictive analytics. Both roles necessitate continuous training and integration of automated technologies to enhance operational accuracy and reduce delays.

Dock Supervisor vs Yard Supervisor Infographic

jobdiv.com

jobdiv.com