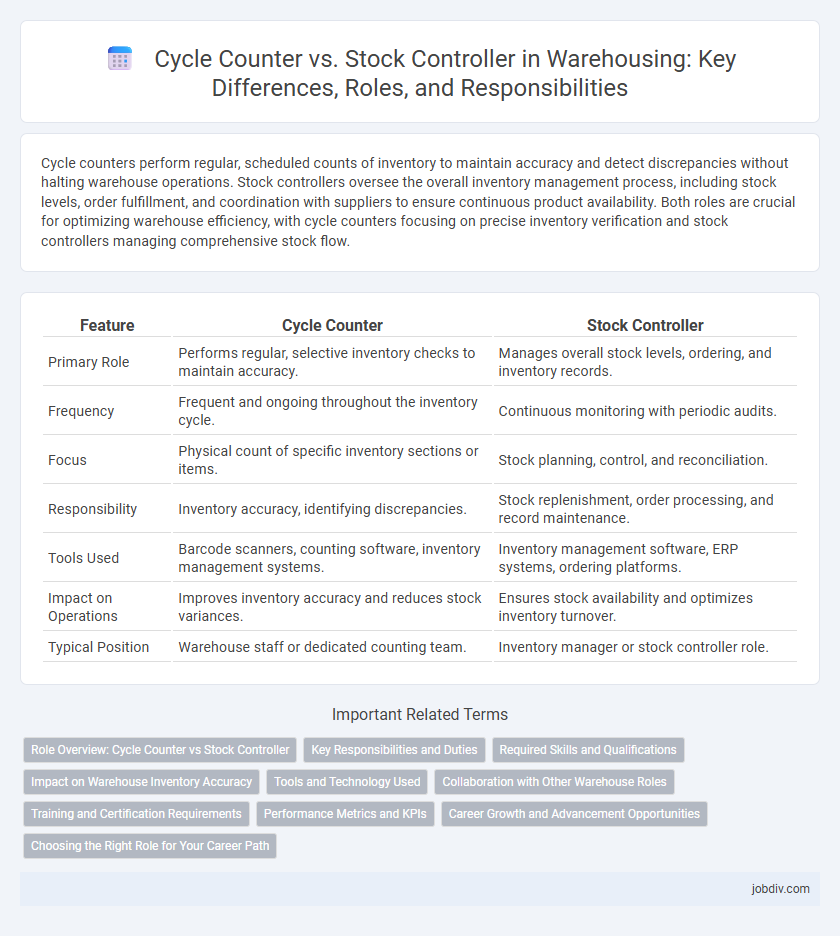

Cycle counters perform regular, scheduled counts of inventory to maintain accuracy and detect discrepancies without halting warehouse operations. Stock controllers oversee the overall inventory management process, including stock levels, order fulfillment, and coordination with suppliers to ensure continuous product availability. Both roles are crucial for optimizing warehouse efficiency, with cycle counters focusing on precise inventory verification and stock controllers managing comprehensive stock flow.

Table of Comparison

| Feature | Cycle Counter | Stock Controller |

|---|---|---|

| Primary Role | Performs regular, selective inventory checks to maintain accuracy. | Manages overall stock levels, ordering, and inventory records. |

| Frequency | Frequent and ongoing throughout the inventory cycle. | Continuous monitoring with periodic audits. |

| Focus | Physical count of specific inventory sections or items. | Stock planning, control, and reconciliation. |

| Responsibility | Inventory accuracy, identifying discrepancies. | Stock replenishment, order processing, and record maintenance. |

| Tools Used | Barcode scanners, counting software, inventory management systems. | Inventory management software, ERP systems, ordering platforms. |

| Impact on Operations | Improves inventory accuracy and reduces stock variances. | Ensures stock availability and optimizes inventory turnover. |

| Typical Position | Warehouse staff or dedicated counting team. | Inventory manager or stock controller role. |

Role Overview: Cycle Counter vs Stock Controller

Cycle Counters systematically perform periodic inventory audits to ensure stock accuracy and identify discrepancies in warehouse operations. Stock Controllers manage the overall inventory flow, including receiving, storing, and dispatching goods while maintaining optimal stock levels and minimizing stockouts. The cycle counter role emphasizes accuracy checks and data validation, whereas the stock controller focuses on inventory management and process coordination.

Key Responsibilities and Duties

Cycle Counters perform regular inventory audits by systematically counting stock to ensure accuracy and identify discrepancies in warehouse records. Stock Controllers manage overall inventory levels, oversee stock replenishment, and coordinate with procurement to maintain optimal warehouse stock flow. Both roles collaborate closely to enhance inventory accuracy and streamline warehouse operations.

Required Skills and Qualifications

Cycle counters require strong attention to detail, basic inventory knowledge, and proficiency with barcode scanners and inventory management software to accurately perform regular stock audits. Stock controllers need advanced organizational skills, expertise in supply chain management, and the ability to analyze inventory data using ERP systems for effective stock level optimization. Both roles demand excellent communication skills and experience in warehouse operations to ensure seamless inventory accuracy and control.

Impact on Warehouse Inventory Accuracy

Cycle counters conduct regular partial inventories, boosting warehouse inventory accuracy by identifying discrepancies early and reducing the need for full physical counts. Stock controllers manage overall stock levels and reorder processes, ensuring data integrity through accurate record-keeping and timely adjustments. The combined efforts of cycle counters and stock controllers significantly enhance real-time inventory accuracy and operational efficiency in warehousing.

Tools and Technology Used

Cycle counters rely heavily on handheld barcode scanners, RFID readers, and inventory management software to perform frequent, partial inventory checks efficiently. Stock controllers utilize advanced warehouse management systems (WMS), automated data capture tools, and integrated ERP software to maintain comprehensive oversight of stock levels and coordinate replenishment tasks. Both roles benefit from mobile computing devices and cloud-based platforms to enhance accuracy and real-time data synchronization in warehousing operations.

Collaboration with Other Warehouse Roles

Cycle Counters and Stock Controllers collaborate closely with warehouse supervisors, inventory analysts, and forklift operators to maintain accurate stock levels and streamline inventory processes. Effective communication between cycle counters and stock controllers ensures discrepancies are quickly identified and resolved, minimizing stock inaccuracies and operational delays. Integration with warehouse management systems allows both roles to share real-time data, enhancing teamwork and improving overall inventory control efficiency.

Training and Certification Requirements

Cycle counters typically require training focused on inventory audit techniques, accuracy verification, and software proficiency, often supported by certifications such as Certified Inventory Auditor (CIA). Stock controllers need comprehensive training in demand forecasting, stock management systems, and leadership skills, with certifications like Certified Supply Chain Professional (CSCP) enhancing their credentials. Both roles demand continuous education in warehouse management software and compliance regulations to maintain operational efficiency.

Performance Metrics and KPIs

Cycle Counters rely on accuracy rate, count frequency, and discrepancy resolution time as primary KPIs to maintain inventory integrity. Stock Controllers emphasize order fulfillment rate, stock turnover ratio, and holding cost efficiency to optimize warehouse performance. Both roles use inventory accuracy and timely reporting as key performance metrics to drive operational excellence.

Career Growth and Advancement Opportunities

Cycle Counters often start their careers focused on inventory accuracy and gain detailed knowledge of stock management, which can lead to advancement into roles such as Inventory Analyst or Warehouse Supervisor. Stock Controllers typically manage broader responsibilities including order fulfillment, stock replenishment, and reporting, positioning themselves for leadership roles like Warehouse Manager or Supply Chain Coordinator. Career growth in warehousing is accelerated by gaining expertise in inventory systems, data analysis, and team management skills relevant to both positions.

Choosing the Right Role for Your Career Path

Cycle Counter specializes in regularly auditing inventory to ensure accuracy and reduce discrepancies, making it ideal for those detail-oriented and skilled in data analysis. Stock Controllers manage overall inventory flow, coordinate stock replenishment, and optimize warehouse efficiency, suitable for candidates with strong organizational and decision-making abilities. Selecting the right role depends on your strengths in precision versus strategic planning within warehousing operations.

Cycle Counter vs Stock Controller Infographic

jobdiv.com

jobdiv.com