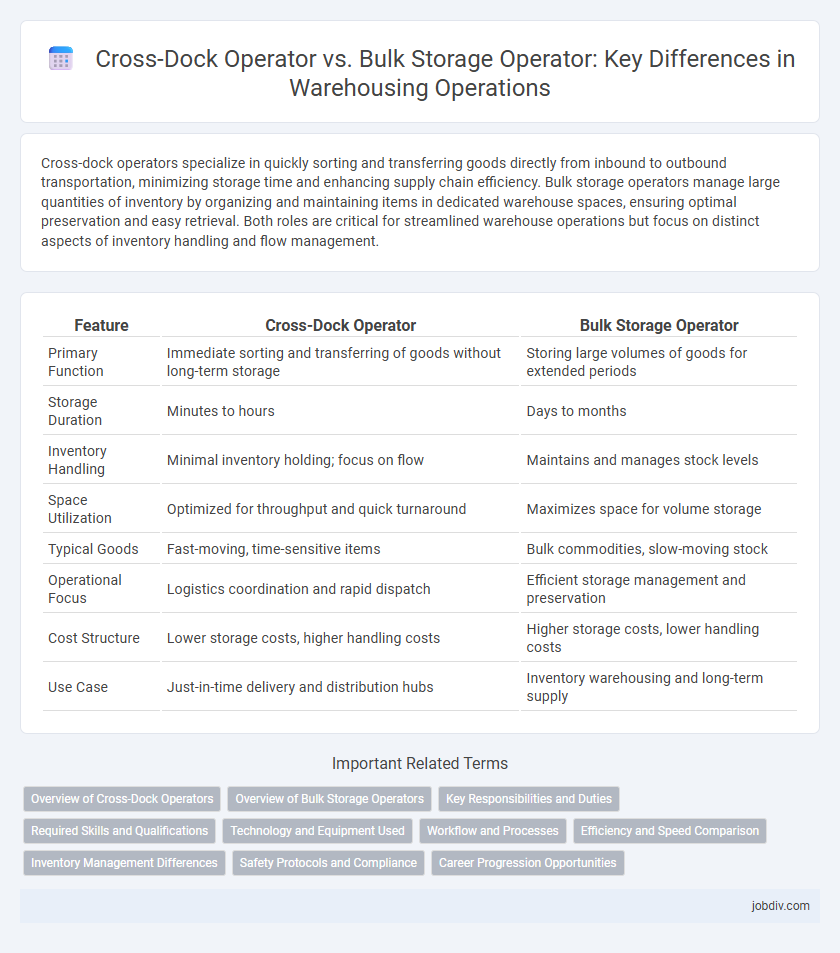

Cross-dock operators specialize in quickly sorting and transferring goods directly from inbound to outbound transportation, minimizing storage time and enhancing supply chain efficiency. Bulk storage operators manage large quantities of inventory by organizing and maintaining items in dedicated warehouse spaces, ensuring optimal preservation and easy retrieval. Both roles are critical for streamlined warehouse operations but focus on distinct aspects of inventory handling and flow management.

Table of Comparison

| Feature | Cross-Dock Operator | Bulk Storage Operator |

|---|---|---|

| Primary Function | Immediate sorting and transferring of goods without long-term storage | Storing large volumes of goods for extended periods |

| Storage Duration | Minutes to hours | Days to months |

| Inventory Handling | Minimal inventory holding; focus on flow | Maintains and manages stock levels |

| Space Utilization | Optimized for throughput and quick turnaround | Maximizes space for volume storage |

| Typical Goods | Fast-moving, time-sensitive items | Bulk commodities, slow-moving stock |

| Operational Focus | Logistics coordination and rapid dispatch | Efficient storage management and preservation |

| Cost Structure | Lower storage costs, higher handling costs | Higher storage costs, lower handling costs |

| Use Case | Just-in-time delivery and distribution hubs | Inventory warehousing and long-term supply |

Overview of Cross-Dock Operators

Cross-dock operators specialize in the rapid transfer of goods directly from inbound to outbound transportation with minimal or no storage time, significantly reducing handling costs and delivery lead times. Their role involves coordinating dock scheduling, sorting, and immediate shipment of products to streamline supply chain efficiency. This approach contrasts with bulk storage operators who focus on long-term inventory holding within warehouse facilities.

Overview of Bulk Storage Operators

Bulk Storage Operators specialize in managing large volumes of goods stored in warehouses for extended periods, optimizing space through efficient stacking and inventory control systems. They handle diverse products such as raw materials, packaged goods, and industrial supplies, ensuring proper labeling, preservation, and timely retrieval. Their expertise in warehouse layout design and inventory management software enhances operational efficiency and minimizes storage costs.

Key Responsibilities and Duties

Cross-Dock Operators manage the rapid transfer of goods directly from inbound to outbound transportation, optimizing flow and minimizing storage time in warehousing environments. Bulk Storage Operators are responsible for organizing, maintaining, and retrieving large quantities of inventory within warehouse storage areas, ensuring efficient space utilization and accurate stock management. Both roles require inventory control skills but differ significantly in handling throughput speed and storage duration.

Required Skills and Qualifications

Cross-dock operators require strong organizational skills, the ability to manage rapid inventory turnover, and proficiency in using warehouse management systems (WMS) to coordinate incoming and outgoing shipments efficiently. Bulk storage operators need expertise in inventory control, knowledge of proper stacking and storage protocols, and experience with heavy machinery such as forklifts to handle large volumes of goods safely. Both roles demand attention to detail, physical stamina, and adherence to safety regulations to maintain operational efficiency and reduce product damage.

Technology and Equipment Used

Cross-Dock Operators rely heavily on automated conveyor systems, barcode scanners, and real-time tracking software to facilitate rapid sorting and transfer of goods directly from inbound to outbound shipments. Bulk Storage Operators utilize heavy-duty forklifts, automated storage and retrieval systems (AS/RS), and warehouse management systems (WMS) designed for efficient space optimization and inventory control. Advanced technologies like RFID tagging and robotic palletizers enhance accuracy and speed in both cross-docking and bulk storage operations, but equipment is tailored to the specific workflow demands of each role.

Workflow and Processes

Cross-dock operators prioritize rapid sorting, staging, and movement of goods directly from inbound to outbound transportation, minimizing storage time and enhancing throughput efficiency. Bulk storage operators manage extensive inventory by systematically organizing, storing, and retrieving large volumes of goods, emphasizing accuracy and space optimization. Workflow for cross-dock roles centers on real-time coordination and quick turnaround, while bulk storage involves scheduled inventory cycles and meticulous stock control processes.

Efficiency and Speed Comparison

Cross-dock operators excel in handling goods with high efficiency and speed by minimizing storage time, enabling rapid transfer of products from inbound to outbound shipments without long-term warehousing. Bulk storage operators manage large quantities of inventory, prioritizing space optimization but typically involve slower access and retrieval times compared to cross-docking. The streamlined workflow of cross-dock operations significantly reduces handling and storage costs, leading to faster order fulfillment and enhanced supply chain responsiveness.

Inventory Management Differences

Cross-dock operators manage inventory by facilitating the rapid transfer of goods directly from inbound to outbound transportation, minimizing storage time and reducing inventory holding costs. Bulk storage operators focus on organizing and maintaining large quantities of products within a warehouse, emphasizing long-term inventory accuracy and space optimization. The primary inventory management difference lies in cross-dock operations prioritizing throughput and velocity, while bulk storage prioritizes stock control and order fulfillment accuracy.

Safety Protocols and Compliance

Cross-Dock Operators follow strict safety protocols to minimize risks associated with rapid unloading and shipment sorting, emphasizing proper personal protective equipment (PPE) usage and adherence to hazardous material handling regulations. Bulk Storage Operators prioritize compliance with fire prevention standards, ensuring correct stacking procedures and regular equipment inspections to prevent collapses and contamination. Both roles require continuous training to meet Occupational Safety and Health Administration (OSHA) standards and maintain warehouse safety certifications.

Career Progression Opportunities

Cross-Dock Operators typically gain skills in fast-paced logistics and real-time inventory management, leading to opportunities in supply chain coordination and distribution supervision. Bulk Storage Operators develop expertise in warehouse storage optimization and large-scale inventory control, positioning them for roles in warehouse management and operations planning. Both paths offer distinct career progression, with Cross-Dock Operators leaning toward dynamic distribution roles and Bulk Storage Operators advancing in strategic warehouse operations.

Cross-Dock Operator vs Bulk Storage Operator Infographic

jobdiv.com

jobdiv.com