Line loaders streamline warehousing operations by efficiently stacking and organizing goods along conveyor lines, maximizing space utilization and reducing load times. Line unloaders specialize in rapidly removing items from conveyor belts, enhancing throughput and minimizing bottlenecks during peak hours. Choosing between line loaders and unloaders depends on specific workflow demands, as both equipment types optimize inventory handling and contribute to seamless warehouse productivity.

Table of Comparison

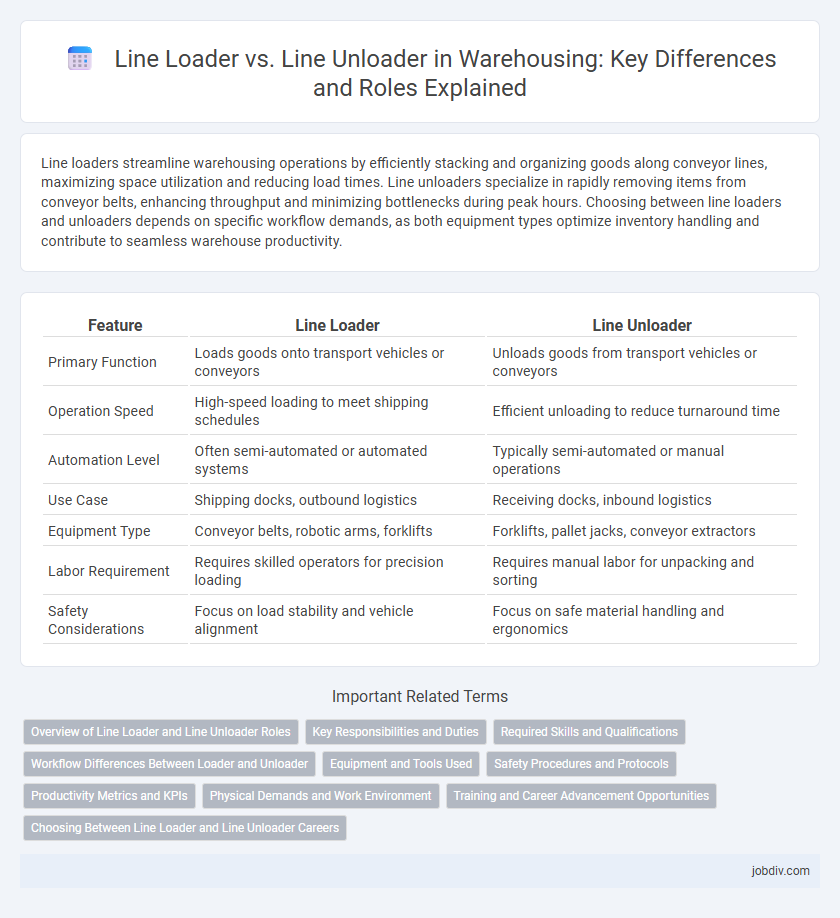

| Feature | Line Loader | Line Unloader |

|---|---|---|

| Primary Function | Loads goods onto transport vehicles or conveyors | Unloads goods from transport vehicles or conveyors |

| Operation Speed | High-speed loading to meet shipping schedules | Efficient unloading to reduce turnaround time |

| Automation Level | Often semi-automated or automated systems | Typically semi-automated or manual operations |

| Use Case | Shipping docks, outbound logistics | Receiving docks, inbound logistics |

| Equipment Type | Conveyor belts, robotic arms, forklifts | Forklifts, pallet jacks, conveyor extractors |

| Labor Requirement | Requires skilled operators for precision loading | Requires manual labor for unpacking and sorting |

| Safety Considerations | Focus on load stability and vehicle alignment | Focus on safe material handling and ergonomics |

Overview of Line Loader and Line Unloader Roles

Line loaders are responsible for efficiently loading goods onto pallets or transportation vehicles, ensuring accurate placement and secure stacking to optimize space and prevent damage. Line unloaders handle the systematic removal and sorting of incoming products from pallets or delivery vehicles, preparing inventory for storage or further processing in the warehouse. Both roles are critical for maintaining workflow continuity, inventory accuracy, and minimizing handling time in warehouse operations.

Key Responsibilities and Duties

Line Loaders are responsible for efficiently loading products onto transportation vehicles, ensuring accurate placement and secure handling to prevent damage during transit. Line Unloaders focus on safely removing goods from incoming shipments, inspecting items for damage, and organizing inventory systematically within the warehouse. Both roles require attention to detail, adherence to safety protocols, and coordination with inventory management systems to maintain operational flow.

Required Skills and Qualifications

Line loaders require proficiency in operating forklifts and pallet jacks, strong physical stamina, and attention to detail to accurately stack and organize inventory. Line unloaders must possess skills in safely handling heavy materials, basic mechanical knowledge for equipment maintenance, and teamwork abilities to efficiently offload incoming shipments. Both roles demand adherence to safety protocols and effective communication skills to ensure smooth warehouse operations.

Workflow Differences Between Loader and Unloader

Line loaders focus on efficiently placing goods onto transport vehicles, ensuring optimal stacking and space utilization to maximize shipment capacity. Line unloaders specialize in swiftly removing items from incoming transport lines, prioritizing sorted and damage-free transfer to storage areas. Workflow differences include loaders emphasizing precise load planning and weight distribution, while unloaders concentrate on rapid item identification and organized staging for inventory processing.

Equipment and Tools Used

Line Loaders utilize conveyor belts, forklifts, and pallet jacks to efficiently move products onto transport vehicles, optimizing loading speed and accuracy. Line Unloaders employ scanning devices, automated sorters, and mobile carts to facilitate quick and organized removal of goods from trucks to storage areas. Both tools are essential for maintaining seamless warehouse operations, reducing manual labor, and improving inventory management.

Safety Procedures and Protocols

Line loaders and line unloaders must adhere to stringent safety procedures to prevent workplace injuries and equipment damage during warehousing operations. Proper personal protective equipment (PPE), clear communication signals, and adherence to loading and unloading protocols are crucial to minimizing risks such as falls, collisions, and load shifts. Regular training in emergency response and equipment maintenance ensures both line loaders and unloaders comply with OSHA standards and promote a safer working environment.

Productivity Metrics and KPIs

Line loaders and line unloaders are crucial in warehousing productivity, directly impacting throughput rates and labor efficiency. Key KPIs for line loaders include units loaded per hour and load accuracy, while line unloaders are measured by unloading speed, error rates, and damage incidence. Optimizing these metrics enhances overall warehouse flow, reduces bottlenecks, and improves order fulfillment times.

Physical Demands and Work Environment

Line loaders require significant physical strength and stamina as they involve manually lifting and moving heavy packages along production lines, often in fast-paced environments with repetitive motions. Line unloaders must also handle heavy loads, but their tasks typically involve sorting and removing items, which demands sustained physical effort and attention to ergonomics to prevent strain. Both roles operate in environments that may be noisy and temperature-controlled, requiring personal protective equipment and adherence to safety protocols to maintain worker health.

Training and Career Advancement Opportunities

Line loaders and line unloaders offer distinct training pathways tailored to their operational roles in warehousing, enhancing skillsets specific to inventory management and material handling. Line loaders often receive instruction on efficient loading techniques, safety protocols, and equipment operation, positioning them for supervisory roles or specialized logistics positions. Conversely, line unloaders develop expertise in rapid receiving processes and quality control, paving career advancement toward supply chain coordination and warehouse management roles.

Choosing Between Line Loader and Line Unloader Careers

Choosing between Line Loader and Line Unloader careers depends on individual strengths and warehouse needs. Line Loaders focus on efficiently organizing and placing products onto conveyors or pallets, requiring strong attention to detail and physical stamina. Line Unloaders specialize in removing and sorting incoming shipments, emphasizing speed and accuracy in handling diverse inventory types.

Line Loader vs Line Unloader Infographic

jobdiv.com

jobdiv.com