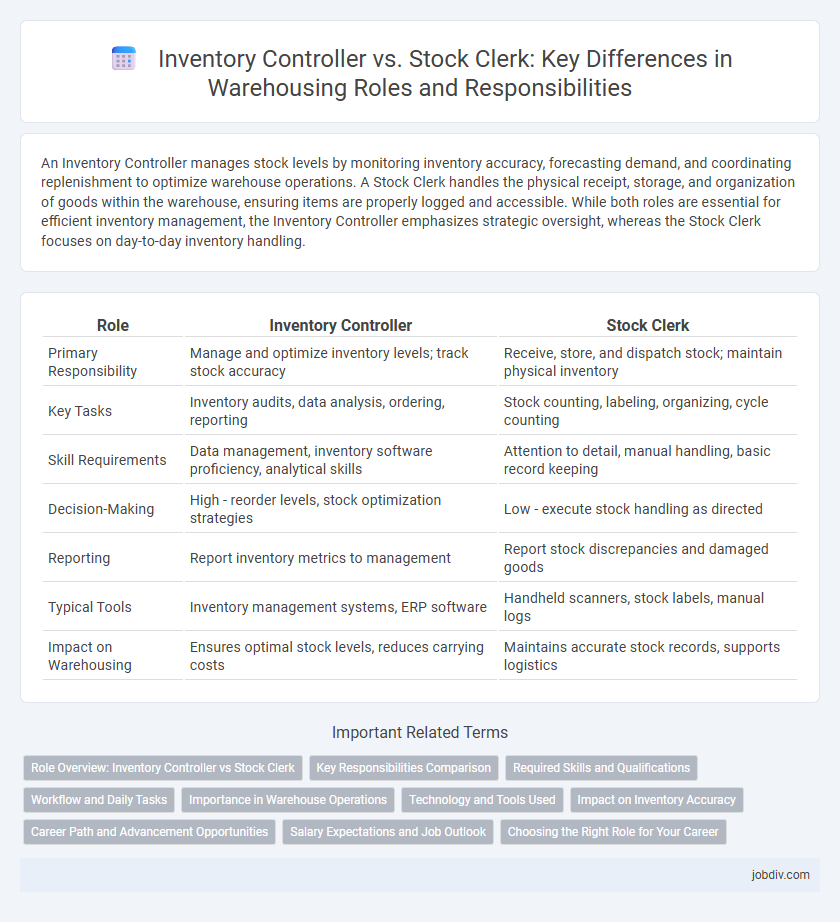

An Inventory Controller manages stock levels by monitoring inventory accuracy, forecasting demand, and coordinating replenishment to optimize warehouse operations. A Stock Clerk handles the physical receipt, storage, and organization of goods within the warehouse, ensuring items are properly logged and accessible. While both roles are essential for efficient inventory management, the Inventory Controller emphasizes strategic oversight, whereas the Stock Clerk focuses on day-to-day inventory handling.

Table of Comparison

| Role | Inventory Controller | Stock Clerk |

|---|---|---|

| Primary Responsibility | Manage and optimize inventory levels; track stock accuracy | Receive, store, and dispatch stock; maintain physical inventory |

| Key Tasks | Inventory audits, data analysis, ordering, reporting | Stock counting, labeling, organizing, cycle counting |

| Skill Requirements | Data management, inventory software proficiency, analytical skills | Attention to detail, manual handling, basic record keeping |

| Decision-Making | High - reorder levels, stock optimization strategies | Low - execute stock handling as directed |

| Reporting | Report inventory metrics to management | Report stock discrepancies and damaged goods |

| Typical Tools | Inventory management systems, ERP software | Handheld scanners, stock labels, manual logs |

| Impact on Warehousing | Ensures optimal stock levels, reduces carrying costs | Maintains accurate stock records, supports logistics |

Role Overview: Inventory Controller vs Stock Clerk

Inventory Controllers oversee inventory accuracy, manage stock levels, and coordinate with procurement to prevent shortages or overstock situations. Stock Clerks perform hands-on tasks such as receiving, storing, and organizing goods, as well as maintaining physical inventory records. Both roles are essential for efficient warehouse operations, with Inventory Controllers focusing on strategic inventory management and Stock Clerks handling daily stock movement.

Key Responsibilities Comparison

Inventory Controllers oversee stock levels by managing inventory data, conducting regular audits, and coordinating with procurement to ensure accurate replenishment. Stock Clerks handle physical stock, including receiving shipments, organizing warehouse items, and preparing goods for dispatch. While Inventory Controllers focus on data accuracy and strategic stock management, Stock Clerks emphasize operational tasks and physical handling within the warehouse.

Required Skills and Qualifications

Inventory Controllers require strong analytical skills, proficiency in inventory management software, and a deep understanding of supply chain processes to ensure accurate stock levels and optimize order fulfillment. Stock Clerks need expertise in physical stock handling, basic computer skills, and attention to detail for tasks such as receiving shipments, organizing warehousing space, and updating stock records. Both roles demand organizational abilities and familiarity with safety regulations, but Inventory Controllers typically hold higher qualifications, often including experience with ERP systems and data analysis.

Workflow and Daily Tasks

Inventory Controllers oversee the entire inventory management process, including forecasting demand, conducting periodic audits, and reconciling stock discrepancies to optimize warehouse efficiency. Stock Clerks handle the physical receipt, organization, and dispatch of goods, ensuring accurate labeling, proper storage, and timely order fulfillment. While Inventory Controllers focus on strategic stock levels and reporting, Stock Clerks execute day-to-day inventory movement and maintain accurate stock records within the warehouse.

Importance in Warehouse Operations

Inventory controllers play a critical role in warehouse operations by managing inventory accuracy, forecasting demand, and minimizing stock discrepancies, directly impacting supply chain efficiency. Stock clerks handle the physical organization, labeling, and movement of goods, ensuring timely order fulfillment and maintaining warehouse cleanliness and safety standards. Both roles are essential; inventory controllers provide strategic oversight while stock clerks execute the operational tasks that keep warehouses running smoothly.

Technology and Tools Used

Inventory Controllers utilize advanced warehouse management systems (WMS), barcode scanners, and RFID technology to monitor stock levels and ensure accurate inventory data. Stock Clerks primarily operate handheld devices and digital spreadsheets for tracking item movement and organizing stock on shelves. Both roles increasingly rely on automation tools and real-time data analytics to optimize inventory accuracy and streamline warehouse operations.

Impact on Inventory Accuracy

Inventory Controllers implement systematic cycle counts and reconcile discrepancies promptly, significantly enhancing inventory accuracy and reducing shrinkage. Stock Clerks perform daily stock movements, picking, and replenishment tasks that directly affect real-time inventory visibility and accuracy. Effective collaboration between both roles ensures robust inventory control, minimizing errors and optimizing stock levels in warehousing operations.

Career Path and Advancement Opportunities

Inventory Controllers typically manage stock levels, analyze inventory data, and coordinate with suppliers, offering clear advancement to roles such as Inventory Manager or Supply Chain Analyst. Stock Clerks primarily handle receiving, storing, and issuing goods, providing foundational warehouse experience but with limited direct pathways to higher management without additional qualifications. Career growth for Inventory Controllers is often faster due to their analytical responsibilities and greater involvement in strategic inventory decisions.

Salary Expectations and Job Outlook

Inventory Controllers typically command higher salaries, averaging $55,000 to $75,000 annually, due to their responsibility for overseeing stock accuracy and implementing inventory management systems. Stock Clerks earn between $30,000 and $45,000 per year, reflecting their role in handling daily stock receipt and organization tasks. The job outlook for Inventory Controllers shows steady growth driven by increased supply chain complexity, while Stock Clerk positions face moderate demand linked to turnover and warehouse expansion.

Choosing the Right Role for Your Career

Inventory Controllers oversee accurate tracking and management of stock levels using advanced ERP systems, requiring analytical skills and attention to detail. Stock Clerks handle physical receiving, storing, and organizing of inventory, emphasizing hands-on operational tasks and reliability. Selecting the right role depends on your preference for data-driven decision-making versus direct warehouse involvement within the warehousing industry.

Inventory Controller vs Stock Clerk Infographic

jobdiv.com

jobdiv.com