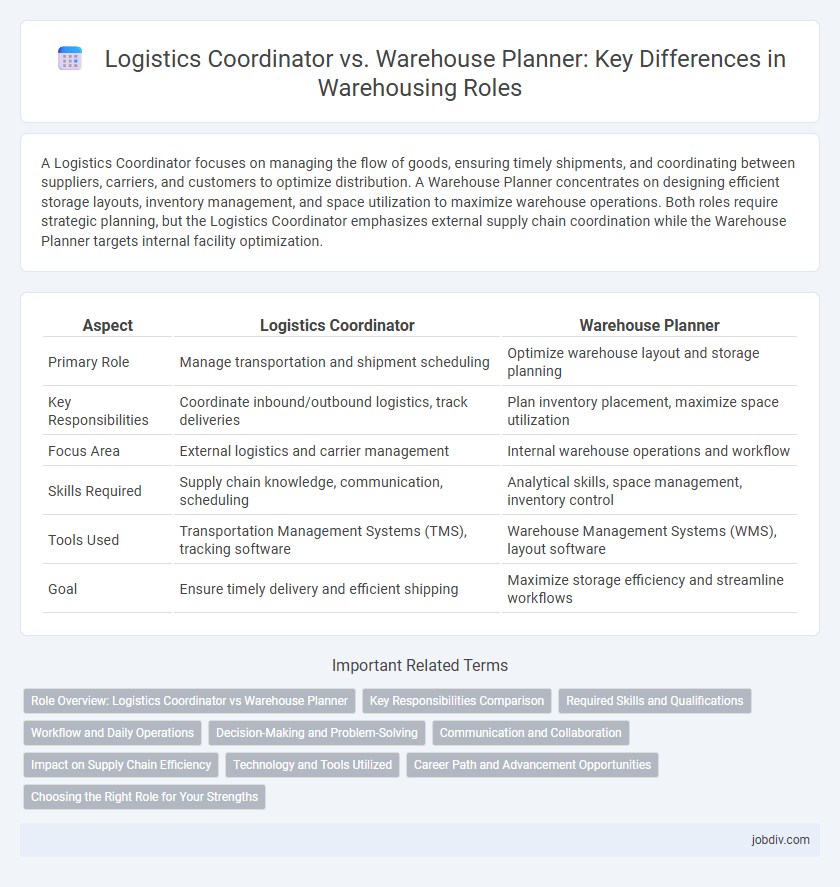

A Logistics Coordinator focuses on managing the flow of goods, ensuring timely shipments, and coordinating between suppliers, carriers, and customers to optimize distribution. A Warehouse Planner concentrates on designing efficient storage layouts, inventory management, and space utilization to maximize warehouse operations. Both roles require strategic planning, but the Logistics Coordinator emphasizes external supply chain coordination while the Warehouse Planner targets internal facility optimization.

Table of Comparison

| Aspect | Logistics Coordinator | Warehouse Planner |

|---|---|---|

| Primary Role | Manage transportation and shipment scheduling | Optimize warehouse layout and storage planning |

| Key Responsibilities | Coordinate inbound/outbound logistics, track deliveries | Plan inventory placement, maximize space utilization |

| Focus Area | External logistics and carrier management | Internal warehouse operations and workflow |

| Skills Required | Supply chain knowledge, communication, scheduling | Analytical skills, space management, inventory control |

| Tools Used | Transportation Management Systems (TMS), tracking software | Warehouse Management Systems (WMS), layout software |

| Goal | Ensure timely delivery and efficient shipping | Maximize storage efficiency and streamline workflows |

Role Overview: Logistics Coordinator vs Warehouse Planner

A Logistics Coordinator manages the flow of goods and information between suppliers, transportation, and customers, ensuring timely delivery and efficient communication across the supply chain. A Warehouse Planner focuses on optimizing warehouse space utilization, inventory management, and workflow processes to improve storage efficiency and order fulfillment rates. Both roles are critical in warehousing operations but emphasize different aspects of supply chain coordination and warehouse optimization.

Key Responsibilities Comparison

Logistics Coordinators manage the flow of goods by coordinating shipments, tracking inventory, and liaising with carriers to ensure timely deliveries. Warehouse Planners focus on optimizing storage layouts, forecasting inventory needs, and scheduling labor to maximize warehouse efficiency. Both roles prioritize inventory accuracy and seamless supply chain operations but differ in their scope of operational planning versus transportation coordination.

Required Skills and Qualifications

A Logistics Coordinator requires strong organizational skills, expertise in inventory management software, and proficiency in coordinating transportation schedules to ensure timely delivery. A Warehouse Planner must have advanced knowledge of supply chain optimization, experience with warehouse management systems (WMS), and skills in demand forecasting and space utilization. Both roles benefit from analytical thinking, attention to detail, and effective communication to streamline warehousing operations and improve efficiency.

Workflow and Daily Operations

A Logistics Coordinator manages the end-to-end workflow by coordinating shipments, tracking inventory movement, and communicating with carriers to ensure timely delivery. A Warehouse Planner focuses on optimizing daily warehouse operations through effective space allocation, inventory control, and workforce scheduling to maximize efficiency. Both roles require seamless collaboration to maintain smooth supply chain processes and reduce operational bottlenecks.

Decision-Making and Problem-Solving

A Logistics Coordinator excels in real-time decision-making by managing the flow of goods, addressing unexpected delays, and coordinating with carriers to optimize delivery schedules. A Warehouse Planner focuses on strategic problem-solving by designing storage layouts, forecasting inventory needs, and optimizing space utilization to improve operational efficiency. Both roles require analytical skills, but the Logistics Coordinator handles dynamic, tactical challenges while the Warehouse Planner engages in long-term, operational planning.

Communication and Collaboration

A Logistics Coordinator excels in communication by managing real-time updates between suppliers, carriers, and warehouse teams to ensure smooth operations. A Warehouse Planner prioritizes collaboration by designing efficient storage layouts and coordinating with inventory managers to optimize space and workflow. Both roles require seamless interaction across departments, but the Logistics Coordinator focuses on external communication, while the Warehouse Planner emphasizes internal teamwork.

Impact on Supply Chain Efficiency

Logistics coordinators optimize supply chain efficiency by managing transportation schedules, coordinating inventory flow, and ensuring timely deliveries that reduce delays and costs. Warehouse planners enhance operational productivity through strategic layout design, capacity planning, and resource allocation, minimizing storage inefficiencies and improving order fulfillment speed. Both roles synergize to streamline processes, balance demand with supply, and maintain seamless movement of goods throughout the supply chain network.

Technology and Tools Utilized

Logistics Coordinators leverage transportation management systems (TMS), real-time GPS tracking, and communication platforms to optimize shipment scheduling and routing. Warehouse Planners utilize warehouse management systems (WMS), inventory optimization software, and automated material handling technologies to enhance storage layout and stock replenishment. Both roles increasingly depend on data analytics and IoT devices to improve operational efficiency and accuracy in supply chain processes.

Career Path and Advancement Opportunities

Logistics Coordinators often advance by gaining expertise in supply chain management, moving into roles such as logistics managers or operations supervisors. Warehouse Planners progress by mastering inventory optimization and space utilization, leading to positions like warehouse managers or supply chain analysts. Both career paths offer growth opportunities through certification and experience, with Logistics Coordinators typically focusing on external coordination and Warehouse Planners specializing in internal warehouse efficiency.

Choosing the Right Role for Your Strengths

A Logistics Coordinator excels in managing transportation schedules, coordinating shipments, and ensuring timely delivery, ideal for professionals strong in communication and real-time problem-solving. A Warehouse Planner focuses on optimizing storage layouts, inventory control, and resource allocation, fitting individuals with analytical skills and strategic foresight. Selecting the right role depends on your strengths: choose Logistics Coordinator if you thrive under dynamic coordination demands, or Warehouse Planner if you prefer strategic planning and operational efficiency.

Logistics Coordinator vs Warehouse Planner Infographic

jobdiv.com

jobdiv.com