RF scanner operators use radio frequency technology to wirelessly communicate with warehouse management systems, enabling real-time data updates and improved inventory accuracy. Barcode scanner operators primarily rely on handheld devices to scan printed codes, which are often limited to line-of-sight and require manual data entry. RF scanning enhances efficiency and reduces errors by providing continuous connectivity throughout the warehouse environment.

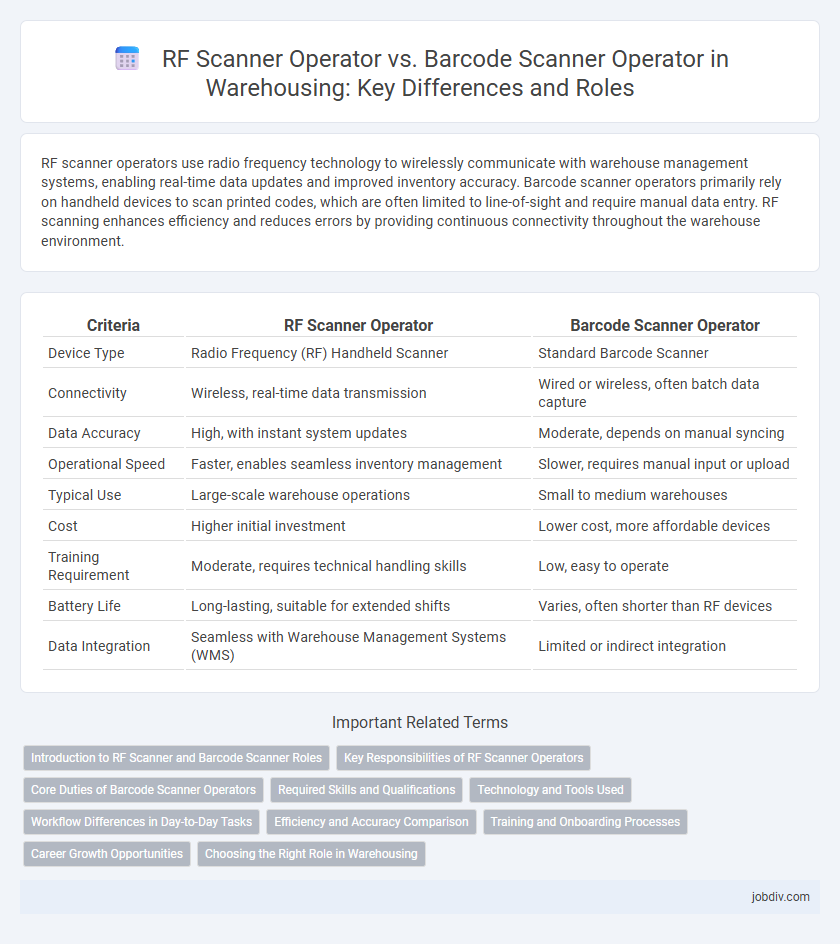

Table of Comparison

| Criteria | RF Scanner Operator | Barcode Scanner Operator |

|---|---|---|

| Device Type | Radio Frequency (RF) Handheld Scanner | Standard Barcode Scanner |

| Connectivity | Wireless, real-time data transmission | Wired or wireless, often batch data capture |

| Data Accuracy | High, with instant system updates | Moderate, depends on manual syncing |

| Operational Speed | Faster, enables seamless inventory management | Slower, requires manual input or upload |

| Typical Use | Large-scale warehouse operations | Small to medium warehouses |

| Cost | Higher initial investment | Lower cost, more affordable devices |

| Training Requirement | Moderate, requires technical handling skills | Low, easy to operate |

| Battery Life | Long-lasting, suitable for extended shifts | Varies, often shorter than RF devices |

| Data Integration | Seamless with Warehouse Management Systems (WMS) | Limited or indirect integration |

Introduction to RF Scanner and Barcode Scanner Roles

RF scanner operators use radio frequency technology to wirelessly collect and transmit real-time inventory data in warehouses, enabling efficient stock management and order processing. Barcode scanner operators primarily utilize handheld devices to read barcodes on products and packages for quick identification, tracking, and accurate data entry. While both roles are critical in supply chain operations, RF scanners provide enhanced mobility and connectivity, supporting seamless communication with warehouse management systems.

Key Responsibilities of RF Scanner Operators

RF Scanner Operators handle real-time inventory tracking using radio frequency devices, ensuring accurate and efficient scan data capture for stock management. They manage order picking, receiving, and shipping processes by scanning items and updating warehouse management systems instantly. Their key responsibilities include verifying product information, maintaining device functionality, and supporting seamless warehouse operations through precise data entry.

Core Duties of Barcode Scanner Operators

Barcode Scanner Operators in warehousing are responsible for accurately scanning product barcodes to ensure precise inventory tracking and order fulfillment. They maintain up-to-date records by entering scanned data into warehouse management systems, facilitating real-time inventory updates. Their core duties include verifying product information, monitoring damaged or misplaced items, and collaborating with other warehouse staff to streamline the shipping and receiving processes.

Required Skills and Qualifications

RF Scanner Operators require proficiency in using radio frequency handheld devices, strong attention to detail, and the ability to navigate warehouse inventory management systems efficiently. Barcode Scanner Operators need skills in operating barcode scanners, basic data entry, and understanding of inventory workflows to accurately track and record stock movements. Both roles demand good communication skills, physical stamina for warehouse environments, and familiarity with safety protocols.

Technology and Tools Used

RF Scanner Operators utilize radio frequency technology to wirelessly communicate with warehouse management systems, enabling real-time inventory tracking and data updates. Barcode Scanner Operators rely on optical devices that read printed barcodes, often requiring line-of-sight scanning to capture product information accurately. The integration of handheld RF scanners offers enhanced mobility and faster data processing compared to traditional barcode scanning tools.

Workflow Differences in Day-to-Day Tasks

RF Scanner Operators use radio frequency technology for real-time data capture, enabling faster inventory updates and seamless communication with warehouse management systems. Barcode Scanner Operators rely on optical scanning of printed labels, which may require manual data entry and result in slower inventory processing. Workflow differences impact efficiency, with RF operators typically handling dynamic inventory tracking while barcode operators focus on static inventory verification.

Efficiency and Accuracy Comparison

RF scanner operators utilize radio frequency technology to capture real-time inventory data, enhancing accuracy by reducing manual entry errors. Barcode scanner operators rely on optical scanning devices that require line-of-sight, which can slow down processes and increase potential misreads. In terms of efficiency and accuracy, RF scanner operators typically outperform barcode scanner operators due to faster data transmission and improved error reduction capabilities in dynamic warehouse environments.

Training and Onboarding Processes

Training for RF scanner operators emphasizes wireless communication protocols and real-time data entry techniques, ensuring seamless integration with warehouse management systems (WMS). Barcode scanner operator onboarding focuses on accurate code recognition and efficient scanning practices to minimize errors during inventory processing. Both roles require familiarization with safety standards and device maintenance for optimal operational efficiency.

Career Growth Opportunities

RF Scanner Operators typically experience faster career growth due to their expertise in wireless communication technologies and integration with warehouse management systems (WMS). Barcode Scanner Operators often have more limited advancement prospects, generally advancing into roles such as inventory clerks or shipping coordinators. Mastery of RF technology opens pathways to supervisory positions and roles in logistics automation, enhancing long-term career potential.

Choosing the Right Role in Warehousing

Choosing the right role in warehousing between an RF scanner operator and a barcode scanner operator depends on technology integration and operational needs. RF scanner operators utilize radio frequency technology for real-time inventory tracking and wireless communication, enhancing efficiency in large or dynamic warehouse environments. Barcode scanner operators rely on optical scanning devices ideal for straightforward barcode reading tasks in more controlled or smaller-scale settings.

RF Scanner Operator vs Barcode Scanner Operator Infographic

jobdiv.com

jobdiv.com