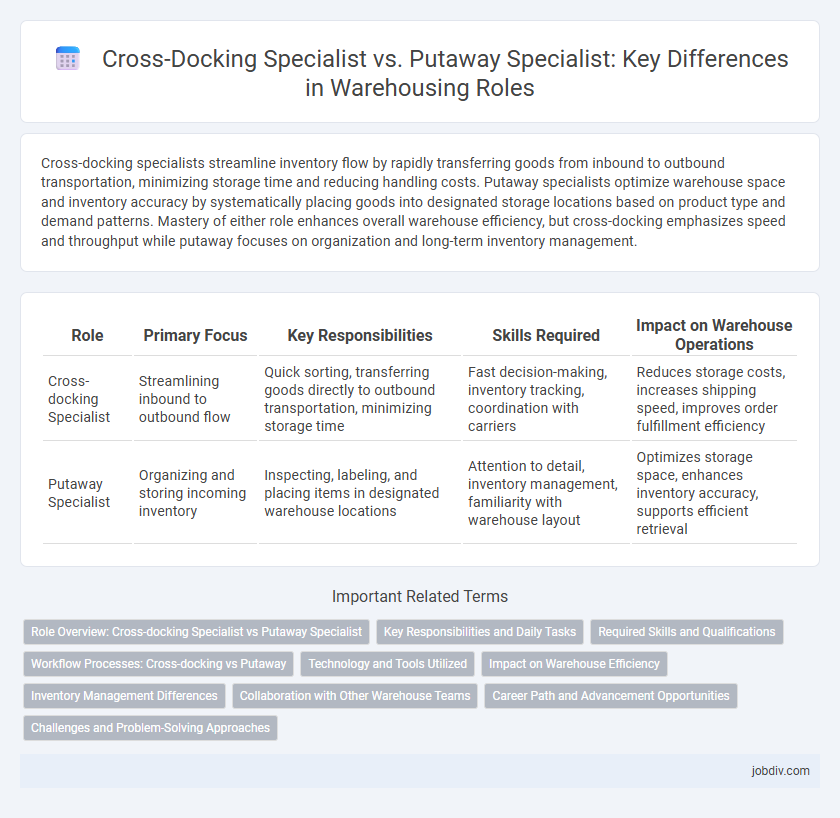

Cross-docking specialists streamline inventory flow by rapidly transferring goods from inbound to outbound transportation, minimizing storage time and reducing handling costs. Putaway specialists optimize warehouse space and inventory accuracy by systematically placing goods into designated storage locations based on product type and demand patterns. Mastery of either role enhances overall warehouse efficiency, but cross-docking emphasizes speed and throughput while putaway focuses on organization and long-term inventory management.

Table of Comparison

| Role | Primary Focus | Key Responsibilities | Skills Required | Impact on Warehouse Operations |

|---|---|---|---|---|

| Cross-docking Specialist | Streamlining inbound to outbound flow | Quick sorting, transferring goods directly to outbound transportation, minimizing storage time | Fast decision-making, inventory tracking, coordination with carriers | Reduces storage costs, increases shipping speed, improves order fulfillment efficiency |

| Putaway Specialist | Organizing and storing incoming inventory | Inspecting, labeling, and placing items in designated warehouse locations | Attention to detail, inventory management, familiarity with warehouse layout | Optimizes storage space, enhances inventory accuracy, supports efficient retrieval |

Role Overview: Cross-docking Specialist vs Putaway Specialist

Cross-docking Specialists streamline warehouse operations by facilitating the immediate transfer of incoming shipments directly to outbound transportation, minimizing storage time and enhancing supply chain efficiency. Putaway Specialists manage the systematic placement of goods into designated storage locations, optimizing space utilization and inventory accuracy within the warehouse. Both roles are critical for operational flow but differ in focus: cross-docking reduces handling and storage time, whereas putaway ensures organized, accessible inventory storage.

Key Responsibilities and Daily Tasks

A Cross-docking Specialist manages the direct transfer of incoming shipments to outbound transportation, minimizing storage time and streamlining inventory flow with tasks such as sorting, routing, and coordinating deliveries. A Putaway Specialist is responsible for efficiently placing received goods into designated storage locations, optimizing warehouse space, and updating inventory systems to maintain accurate stock records. Both roles require strong attention to detail and coordination, but the Cross-docking Specialist focuses on rapid processing of goods while the Putaway Specialist ensures organized and systematic storage.

Required Skills and Qualifications

Cross-docking Specialists require expertise in fast-paced inventory transfer, strong organizational skills, and proficiency with logistics software to efficiently coordinate inbound and outbound shipments. Putaway Specialists need in-depth knowledge of warehouse layout, attention to detail, and experience in using warehouse management systems (WMS) to accurately store goods. Both roles demand physical stamina, teamwork, and a clear understanding of safety protocols in warehousing environments.

Workflow Processes: Cross-docking vs Putaway

Cross-docking specialists coordinate the rapid transfer of inbound goods directly to outbound transportation, minimizing storage time and accelerating inventory turnover. Putaway specialists manage the systematic placement of received goods into designated warehouse locations, optimizing storage efficiency and inventory accessibility. The cross-docking workflow emphasizes speed and precision in sorting, while putaway focuses on accurate inventory placement and space utilization within the warehouse.

Technology and Tools Utilized

Cross-docking specialists leverage real-time tracking systems, automated sorting conveyors, and advanced warehouse management software (WMS) to ensure rapid transfer of incoming shipments to outbound transportation with minimal storage time. Putaway specialists employ barcode scanners, RFID technology, and optimized slotting algorithms within WMS to efficiently assign and record inventory locations, maximizing storage space and retrieval speed. Both roles depend heavily on integrated technology platforms to enhance accuracy and operational efficiency in modern warehousing environments.

Impact on Warehouse Efficiency

Cross-docking specialists streamline warehouse efficiency by minimizing storage time and accelerating product flow directly from inbound to outbound transportation, significantly reducing handling and inventory costs. Putaway specialists enhance accuracy and inventory management by strategically placing goods in optimized locations, improving space utilization and retrieval speed. Efficient coordination between both roles ensures balanced throughput, reducing delays and maximizing overall operational productivity in warehousing.

Inventory Management Differences

Cross-docking specialists optimize inventory flow by minimizing storage time, transferring goods directly from receiving to shipping docks to reduce handling and holding costs. Putaway specialists focus on accurate inventory placement within warehouse storage locations, enhancing organization and retrieval efficiency. While cross-docking accelerates throughput and decreases inventory holding, putaway ensures precise inventory tracking and maximizes warehouse space utilization.

Collaboration with Other Warehouse Teams

Cross-docking specialists coordinate closely with receiving and shipping teams to ensure rapid transfer of goods without long-term storage, optimizing inventory flow and reducing handling time. Putaway specialists collaborate with inventory control and storage teams to accurately place products in designated locations, improving warehouse organization and stock accuracy. Effective communication between these roles enhances warehouse efficiency by balancing fast throughput with systematic inventory management.

Career Path and Advancement Opportunities

Cross-docking Specialists typically advance by mastering inventory flow optimization and logistics coordination, leading to roles in supply chain management or operations supervision. Putaway Specialists often progress through expertise in warehouse layout planning and inventory accuracy, moving into positions like inventory control manager or warehouse operations manager. Both paths offer advancement through increasing responsibilities in efficiency, technology integration, and team leadership within warehousing operations.

Challenges and Problem-Solving Approaches

Cross-docking specialists face challenges in synchronizing inbound and outbound shipments to minimize storage time and reduce lead times, requiring real-time coordination and advanced tracking systems to optimize flow. Putaway specialists encounter difficulties managing space allocation for incoming goods, necessitating efficient inventory mapping and prioritization algorithms to streamline storage and retrieval. Both roles demand problem-solving approaches that leverage warehouse management systems (WMS) and data analytics to enhance operational accuracy and throughput.

Cross-docking Specialist vs Putaway Specialist Infographic

jobdiv.com

jobdiv.com