Material handlers and material movers play distinct roles in warehousing operations, where material handlers are responsible for organizing, storing, and retrieving inventory within the warehouse. Material movers focus on transporting goods between different locations, such as loading docks, storage areas, and shipping zones, using equipment like forklifts and pallet jacks. Efficient coordination between material handlers and material movers optimizes workflow, reducing handling time and increasing overall productivity.

Table of Comparison

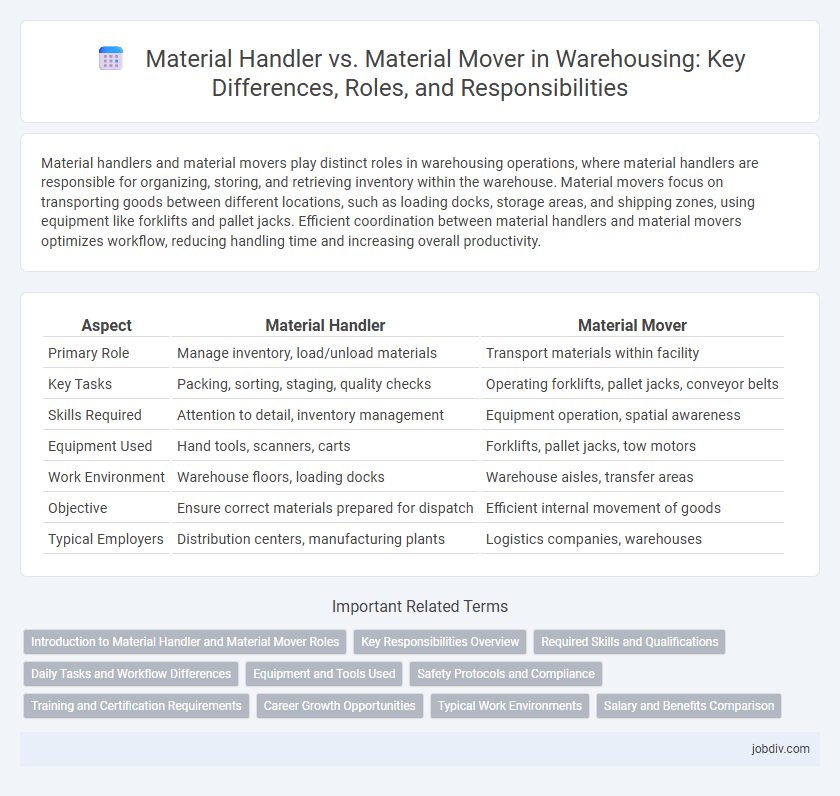

| Aspect | Material Handler | Material Mover |

|---|---|---|

| Primary Role | Manage inventory, load/unload materials | Transport materials within facility |

| Key Tasks | Packing, sorting, staging, quality checks | Operating forklifts, pallet jacks, conveyor belts |

| Skills Required | Attention to detail, inventory management | Equipment operation, spatial awareness |

| Equipment Used | Hand tools, scanners, carts | Forklifts, pallet jacks, tow motors |

| Work Environment | Warehouse floors, loading docks | Warehouse aisles, transfer areas |

| Objective | Ensure correct materials prepared for dispatch | Efficient internal movement of goods |

| Typical Employers | Distribution centers, manufacturing plants | Logistics companies, warehouses |

Introduction to Material Handler and Material Mover Roles

Material handlers play a crucial role in warehousing by managing and organizing inventory, ensuring accurate receipt, storage, and distribution of materials within the facility. Material movers specialize in transporting goods safely and efficiently between different locations, using equipment like forklifts, pallet jacks, and conveyors to optimize workflow. Both roles are essential for maintaining operational efficiency, minimizing errors, and supporting supply chain management tasks.

Key Responsibilities Overview

Material handlers manage inventory by receiving, storing, and distributing materials within warehouses, ensuring accurate documentation and proper equipment use. Material movers focus on transporting goods efficiently between locations using forklifts, pallet jacks, or conveyor systems, prioritizing safety and timely delivery. Both roles require coordination with warehouse teams to maintain operational flow and prevent delays in supply chain processes.

Required Skills and Qualifications

Material Handlers require skills in inventory management, equipment operation such as forklifts, and strong organizational abilities to ensure efficient stock handling and storage. Material Movers need physical strength, knowledge of safety protocols, and the ability to operate various moving machinery, including pallet jacks and conveyor systems, to transport goods within the warehouse. Both roles benefit from attention to detail, time management, and experience with warehouse management software for optimal workflow.

Daily Tasks and Workflow Differences

Material Handlers primarily focus on receiving, storing, and organizing inventory within the warehouse, ensuring accurate stock levels through meticulous data entry and inspection tasks. Material Movers are responsible for transporting materials between different locations in the warehouse or production areas, using equipment such as forklifts and pallet jacks to facilitate efficient workflow and reduce bottlenecks. The daily tasks of Material Handlers emphasize inventory control and preparation, while Material Movers concentrate on material transport and timely delivery to support continuous operations.

Equipment and Tools Used

Material handlers typically utilize equipment such as forklifts, pallet jacks, and conveyor systems to efficiently transport and organize goods within the warehouse. Material movers often rely on larger machinery like automated guided vehicles (AGVs), cranes, and heavy-duty trucks to handle bulk materials and facilitate loading or unloading processes. The choice of tools directly impacts operational efficiency and safety, with material handlers focusing on precision movement and material movers prioritizing heavy lifting and long-distance transport.

Safety Protocols and Compliance

Material handlers and material movers both play crucial roles in warehousing safety protocols and compliance by adhering to OSHA standards and proper equipment usage guidelines. Material handlers focus on the safe handling, storage, and organization of goods, ensuring compliance with hazard communication and PPE (personal protective equipment) requirements. Material movers operate machinery such as forklifts and pallet jacks, following strict operational safety procedures and regular maintenance checks to prevent workplace injuries and maintain regulatory compliance.

Training and Certification Requirements

Material handlers typically require basic training focused on safe handling, inventory management, and equipment operation, with certification often needed for forklift use. Material movers usually require more advanced training in equipment operation such as cranes, pallet jacks, and heavy machinery, plus certifications aligned with OSHA standards or industry-specific regulations. Both roles emphasize safety protocols, but material movers face stricter certification requirements due to the complexity and risk of moving large or hazardous materials.

Career Growth Opportunities

Material Handlers typically engage in tasks such as receiving, storing, and distributing materials, offering foundational skills that pave the way for advancement to supervisory or specialized logistics roles. Material Movers, who often operate forklifts and transport goods within warehouses, can leverage their equipment operation expertise to progress into positions like forklift instructors or warehouse operations managers. Career growth opportunities in warehousing favor professionals who combine hands-on material handling skills with certifications in inventory management or equipment operation, enhancing prospects for leadership roles.

Typical Work Environments

Material Handlers typically work in warehouses, distribution centers, and manufacturing plants, managing inventory and operating forklifts or pallet jacks to move materials within confined indoor spaces. Material Movers often operate in more dynamic environments such as shipping docks, freight terminals, and construction sites, where they handle loading and unloading heavy equipment or bulk materials. Both roles require familiarity with safety protocols and the ability to navigate various terrain types depending on the warehousing or logistics setting.

Salary and Benefits Comparison

Material handlers typically earn an average salary of $32,000 to $40,000 annually, while material movers can expect slightly higher wages ranging from $35,000 to $45,000, reflecting the increased physical demands of the role. Benefits for both positions often include health insurance, retirement plans, and paid time off, but material movers may receive additional compensation such as hazard pay or overtime due to the nature of their tasks. Employers prioritize safety training and ergonomic equipment in benefits packages to reduce injury risks and improve job performance for both material handlers and material movers.

Material Handler vs Material Mover Infographic

jobdiv.com

jobdiv.com