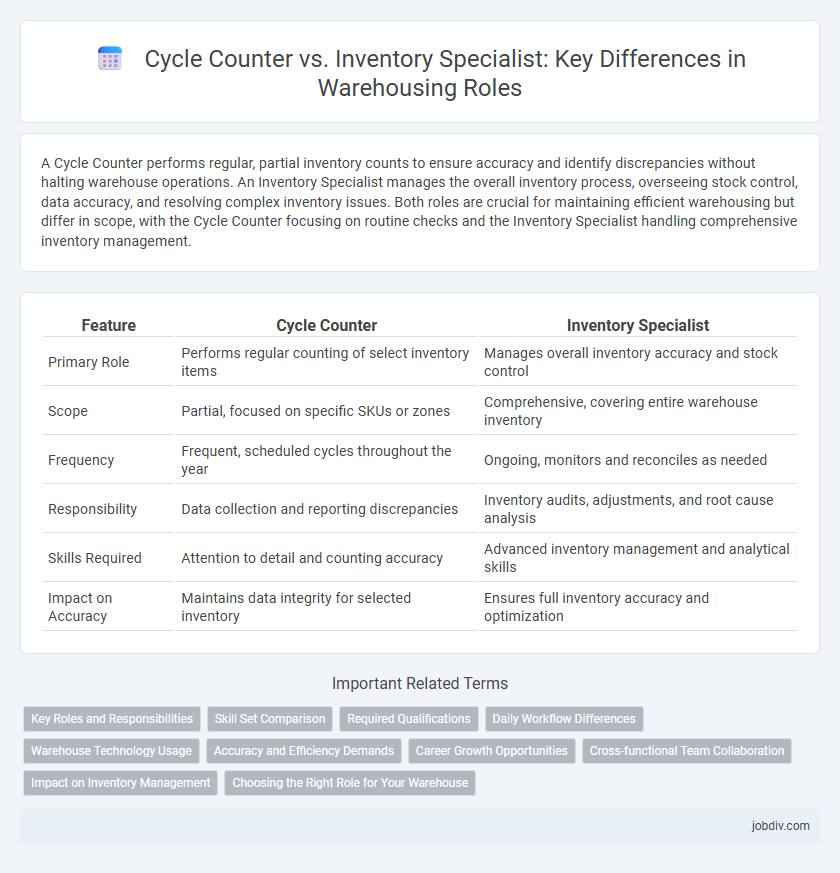

A Cycle Counter performs regular, partial inventory counts to ensure accuracy and identify discrepancies without halting warehouse operations. An Inventory Specialist manages the overall inventory process, overseeing stock control, data accuracy, and resolving complex inventory issues. Both roles are crucial for maintaining efficient warehousing but differ in scope, with the Cycle Counter focusing on routine checks and the Inventory Specialist handling comprehensive inventory management.

Table of Comparison

| Feature | Cycle Counter | Inventory Specialist |

|---|---|---|

| Primary Role | Performs regular counting of select inventory items | Manages overall inventory accuracy and stock control |

| Scope | Partial, focused on specific SKUs or zones | Comprehensive, covering entire warehouse inventory |

| Frequency | Frequent, scheduled cycles throughout the year | Ongoing, monitors and reconciles as needed |

| Responsibility | Data collection and reporting discrepancies | Inventory audits, adjustments, and root cause analysis |

| Skills Required | Attention to detail and counting accuracy | Advanced inventory management and analytical skills |

| Impact on Accuracy | Maintains data integrity for selected inventory | Ensures full inventory accuracy and optimization |

Key Roles and Responsibilities

Cycle counters conduct regular audits by physically verifying inventory to ensure accuracy without disrupting warehouse operations. Inventory specialists manage stock levels, coordinate replenishment, analyze inventory data, and resolve discrepancies to maintain optimal inventory control. Both roles are critical for effective warehouse management, with cycle counters focusing on verification and inventory specialists emphasizing overall inventory optimization.

Skill Set Comparison

Cycle Counters excel in accuracy, time management, and data entry skills to perform precise inventory counts regularly within warehouses. Inventory Specialists demonstrate advanced analytical capabilities, proficiency in inventory management software, and strong problem-solving skills to oversee stock levels, reconcile discrepancies, and optimize supply chain efficiency. Both roles require attention to detail and familiarity with warehouse operations, but Inventory Specialists typically possess a broader expertise in inventory forecasting and reporting.

Required Qualifications

Cycle Counters require strong attention to detail, basic data entry skills, and familiarity with inventory management software to efficiently perform regular stock audits. Inventory Specialists need advanced knowledge of warehouse operations, expertise in inventory control methodologies, and proficiency in analytical tools like Excel or ERP systems to manage stock accuracy and optimize supply chain processes. Both roles demand physical stamina and problem-solving abilities but differ primarily in the complexity of inventory analysis and reporting responsibilities.

Daily Workflow Differences

Cycle counters perform routine, scheduled counts of inventory items to maintain ongoing accuracy without disrupting daily operations, focusing on identifying discrepancies and updating stock records. Inventory specialists manage broader inventory controls, including receiving, storage, order fulfillment, and periodic audits, integrating data analysis and inventory forecasting into their daily tasks. While cycle counters emphasize continuous stock verification, inventory specialists oversee comprehensive inventory management and process optimization.

Warehouse Technology Usage

Cycle counters utilize advanced warehouse technology such as barcode scanners and RFID systems to perform regular, systematic audits of inventory accuracy, ensuring real-time data updates and minimizing discrepancies. Inventory specialists leverage warehouse management software (WMS) to analyze stock levels, forecast demand, and optimize storage layouts, enhancing operational efficiency and reducing stockouts. Both roles depend heavily on integrated technology platforms to streamline inventory control and improve overall warehouse productivity.

Accuracy and Efficiency Demands

Cycle counters deliver high accuracy through regular inventory checks, minimizing discrepancies and ensuring real-time stock data. Inventory specialists enhance efficiency by analyzing data trends and optimizing stock levels to prevent overstocking or stockouts. Both roles complement each other, balancing meticulous accuracy with strategic inventory management in warehousing operations.

Career Growth Opportunities

Cycle Counters gain hands-on experience with inventory accuracy and data analysis, building a foundation for advancing into supervisory roles. Inventory Specialists develop expertise in managing complex stock systems and compliance protocols, positioning themselves for leadership positions in warehouse management or supply chain coordination. Both roles offer pathways for career growth, with Inventory Specialists often accessing broader operational responsibilities and cycle counters frequently progressing through targeted training programs.

Cross-functional Team Collaboration

Cycle counters and inventory specialists enhance warehouse accuracy through cross-functional team collaboration by integrating real-time data sharing and coordinated stock verification processes. Cycle counters perform ongoing, targeted counts that enable inventory specialists to analyze discrepancies, optimize replenishment strategies, and streamline warehouse operations. This collaboration reduces stock variances, improves order fulfillment rates, and maintains inventory integrity across supply chain functions.

Impact on Inventory Management

Cycle counters enhance inventory accuracy by performing regular, targeted stock audits that identify discrepancies early, reducing stockouts and overstock situations. Inventory specialists oversee comprehensive inventory control processes, including reconciliation, data analysis, and implementing corrective actions to maintain long-term stock integrity. The combined efforts of cycle counters and inventory specialists significantly improve inventory management efficiency, minimize errors, and optimize supply chain performance.

Choosing the Right Role for Your Warehouse

Selecting between a Cycle Counter and an Inventory Specialist hinges on your warehouse's operational needs and accuracy goals. Cycle Counters excel in maintaining continuous inventory accuracy through regular, systematic counts, reducing downtime and supporting just-in-time inventory models. Inventory Specialists provide comprehensive oversight, managing stock levels, addressing discrepancies, and optimizing inventory flow to enhance overall warehouse efficiency and cost control.

Cycle Counter vs Inventory Specialist Infographic

jobdiv.com

jobdiv.com