Material handlers primarily manage the physical movement, storage, and organization of goods within a warehouse, ensuring efficient inventory control and minimizing damage during handling. Logistics handlers coordinate the broader supply chain activities, including receiving, shipping, and the documentation required to facilitate smooth transportation and delivery processes. Understanding the distinct roles enhances warehouse efficiency and aligns operational tasks with strategic supply chain goals.

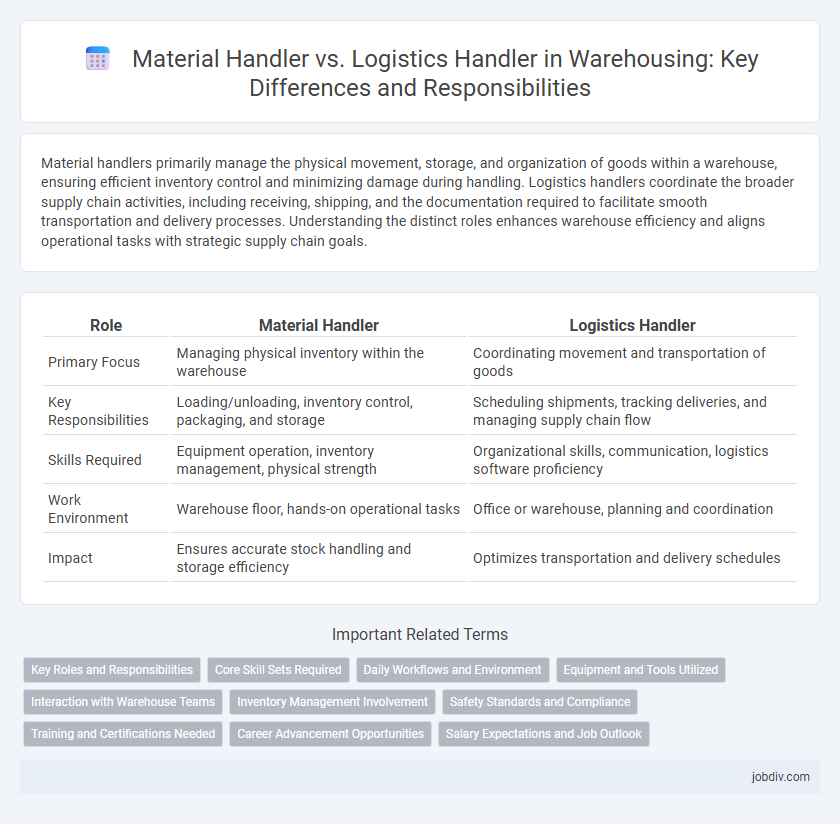

Table of Comparison

| Role | Material Handler | Logistics Handler |

|---|---|---|

| Primary Focus | Managing physical inventory within the warehouse | Coordinating movement and transportation of goods |

| Key Responsibilities | Loading/unloading, inventory control, packaging, and storage | Scheduling shipments, tracking deliveries, and managing supply chain flow |

| Skills Required | Equipment operation, inventory management, physical strength | Organizational skills, communication, logistics software proficiency |

| Work Environment | Warehouse floor, hands-on operational tasks | Office or warehouse, planning and coordination |

| Impact | Ensures accurate stock handling and storage efficiency | Optimizes transportation and delivery schedules |

Key Roles and Responsibilities

Material Handlers manage the receipt, storage, and movement of inventory within warehouses, ensuring accurate order picking, packing, and inventory tracking. Logistics Handlers coordinate transportation, distribution schedules, and shipment documentation to optimize supply chain efficiency and on-time delivery. Both roles require attention to detail and coordination, but Material Handlers focus on internal stock management while Logistics Handlers handle external distribution processes.

Core Skill Sets Required

Material handlers require core skills in inventory management, efficient loading and unloading techniques, and the operation of forklifts and pallet jacks to ensure smooth warehouse flow. Logistics handlers focus on supply chain coordination, route optimization, and shipment tracking systems to enhance delivery accuracy and timeliness. Both roles demand strong organizational abilities and knowledge of warehouse management software for effective inventory control and order fulfillment.

Daily Workflows and Environment

Material handlers primarily manage the receipt, storage, and movement of goods within warehouses using equipment like forklifts and pallet jacks, ensuring accurate inventory placement and order fulfillment. Logistics handlers coordinate the broader supply chain activities, including shipment scheduling, tracking, and communication with carriers and suppliers to optimize delivery timelines and reduce transportation costs. Daily workflows for material handlers emphasize hands-on physical tasks in dynamic warehouse environments, while logistics handlers focus on administrative coordination and real-time problem-solving in office or control room settings.

Equipment and Tools Utilized

Material handlers primarily use forklifts, pallet jacks, and conveyor belts to move and store goods within warehouses, ensuring efficient inventory management. Logistics handlers utilize advanced tracking systems, barcode scanners, and warehouse management software to coordinate shipments and streamline supply chain operations. Both roles rely on hand trucks and safety gear, but logistics handlers focus more on technology-driven tools for real-time data and shipment accuracy.

Interaction with Warehouse Teams

Material handlers coordinate closely with warehouse teams to efficiently manage inventory placement, retrieval, and quality checks, ensuring seamless stock flow within storage areas. Logistics handlers focus on synchronizing shipment schedules, order fulfillment, and transportation logistics by collaborating with warehouse supervisors and inventory planners. Effective communication between material handlers and logistics handlers enhances overall warehouse operation, minimizing delays and optimizing resource allocation.

Inventory Management Involvement

Material handlers primarily focus on the physical movement, storage, and organization of inventory within the warehouse, ensuring items are accurately received, stored, and prepared for shipment. Logistics handlers coordinate inventory management with broader supply chain activities, including tracking stock levels, forecasting demand, and optimizing warehouse layout to improve inventory turnover and reduce holding costs. Both roles are essential for effective inventory accuracy, but logistics handlers typically integrate inventory data with transportation and distribution processes for streamlined operations.

Safety Standards and Compliance

Material Handlers and Logistics Handlers both play critical roles in warehousing environments, with distinct responsibilities impacting safety standards and compliance. Material Handlers focus on the safe movement, storage, and inventory control of physical goods, strictly adhering to OSHA regulations and using proper lifting techniques and personal protective equipment (PPE) to prevent workplace injuries. Logistics Handlers ensure compliance with transportation safety standards, secure packaging protocols, and accurate documentation to meet both regulatory requirements and internal quality controls, minimizing risks throughout the supply chain.

Training and Certifications Needed

Material handlers require training in inventory management, equipment operation like forklifts, and safety protocols, often needing certifications such as OSHA Forklift Operator and Hazardous Materials Handling. Logistics handlers focus on broader supply chain knowledge, including warehouse management systems (WMS), transportation coordination, and may require certifications like Certified Logistics Associate (CLA) or Certified Logistics Technician (CLT). Both roles emphasize compliance with safety standards, but logistics handlers typically pursue advanced certifications to manage complex logistical processes efficiently.

Career Advancement Opportunities

Material Handlers typically advance by gaining expertise in inventory management and equipment operation, leading to roles such as forklift operator or warehouse supervisor. Logistics Handlers often progress through mastering supply chain coordination and transportation management, advancing to positions like logistics coordinator or distribution manager. Both career paths emphasize skills development and certifications that enhance promotion potential within warehousing and distribution sectors.

Salary Expectations and Job Outlook

Material handlers typically earn an average salary ranging from $29,000 to $40,000 annually, influenced by factors such as experience and location, while logistics handlers often command higher wages, averaging between $35,000 and $50,000 due to their broader responsibilities including inventory coordination and supply chain management. The job outlook for material handlers is projected to grow steadily, driven by expanding warehousing and distribution needs, whereas logistics handlers face stronger demand growth, reflecting the increasing complexity of global supply chains and e-commerce expansion. Employers value logistics handlers for their critical role in optimizing operations, which contributes to their competitive compensation and robust career advancement opportunities.

Material Handler vs Logistics Handler Infographic

jobdiv.com

jobdiv.com