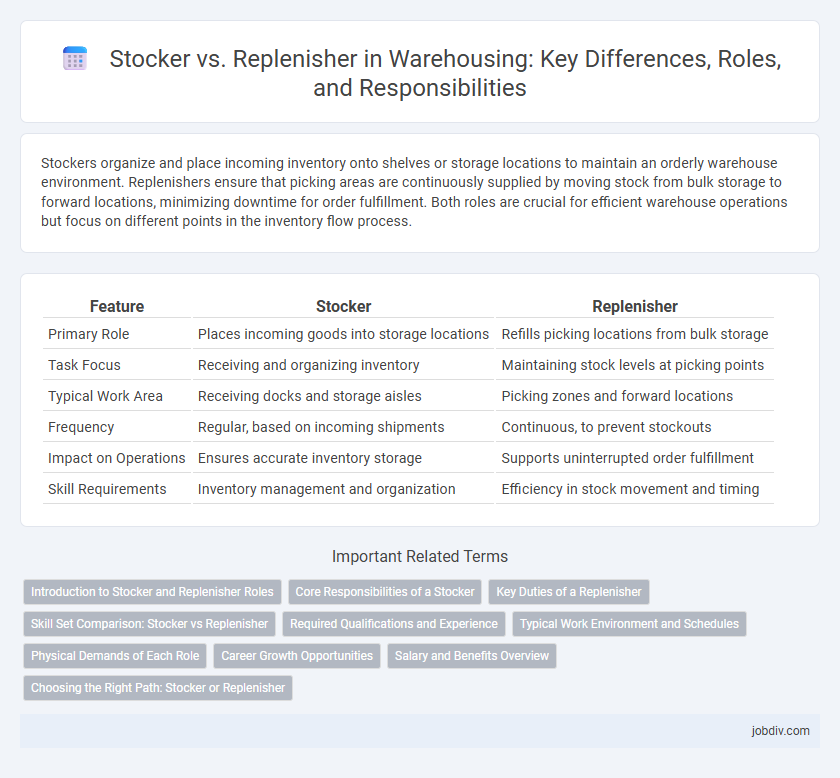

Stockers organize and place incoming inventory onto shelves or storage locations to maintain an orderly warehouse environment. Replenishers ensure that picking areas are continuously supplied by moving stock from bulk storage to forward locations, minimizing downtime for order fulfillment. Both roles are crucial for efficient warehouse operations but focus on different points in the inventory flow process.

Table of Comparison

| Feature | Stocker | Replenisher |

|---|---|---|

| Primary Role | Places incoming goods into storage locations | Refills picking locations from bulk storage |

| Task Focus | Receiving and organizing inventory | Maintaining stock levels at picking points |

| Typical Work Area | Receiving docks and storage aisles | Picking zones and forward locations |

| Frequency | Regular, based on incoming shipments | Continuous, to prevent stockouts |

| Impact on Operations | Ensures accurate inventory storage | Supports uninterrupted order fulfillment |

| Skill Requirements | Inventory management and organization | Efficiency in stock movement and timing |

Introduction to Stocker and Replenisher Roles

Stockers are warehouse personnel responsible for placing incoming inventory onto shelves, ensuring accurate product placement and stock organization. Replenishers monitor inventory levels and transfer products from storage to picking locations to maintain adequate stock for order fulfillment. Both roles are crucial for efficient warehouse operations, contributing to streamlined inventory management and improved order accuracy.

Core Responsibilities of a Stocker

Stockers in warehousing primarily focus on receiving, unpacking, and organizing inventory on shelves or storage areas to maintain stock levels and ensure easy accessibility. Their core responsibilities include verifying deliveries, labeling products accurately, and rotating stock based on expiration dates or FIFO (First-In, First-Out) principles. Efficient stock replenishment supports seamless order fulfillment and reduces storage discrepancies, enhancing overall warehouse productivity.

Key Duties of a Replenisher

A Replenisher is responsible for maintaining optimal inventory levels by refilling shelves, storage areas, and workstations with products from the warehouse or receiving docks. Key duties include monitoring stock quantities, verifying product accuracy, and organizing items to ensure efficient accessibility for order pickers. This role ensures continuous stock availability, reduces downtime, and supports overall warehouse productivity.

Skill Set Comparison: Stocker vs Replenisher

Stockers typically require skills in inventory management, organization, and physical stamina to efficiently place products on shelves while maintaining accuracy. Replenishers focus on skills related to supply chain coordination, real-time stock monitoring, and restocking efficiency to ensure continuous product availability. Both roles demand attention to detail and time management, but stockers emphasize shelf arrangement whereas replenishers prioritize inventory flow and demand forecasting.

Required Qualifications and Experience

Stockers typically require basic warehouse experience and knowledge of inventory management systems, with strong attention to detail and physical stamina for manual tasks. Replenishers often need additional qualifications such as familiarity with supply chain processes, data entry skills, and experience in coordinating stock levels to prevent shortages. Both roles benefit from safety certifications and the ability to operate warehouse equipment efficiently.

Typical Work Environment and Schedules

Stockers typically work in large retail or warehouse settings where they handle inventory during off-peak hours, often requiring night or early morning shifts to restock shelves. Replenishers operate in similar environments but focus on maintaining inventory levels throughout operating hours, with schedules frequently aligned to business hours and peak times. Both roles demand physical stamina and flexibility, though stockers may face more isolated work periods while replenishers engage more with active sales floors.

Physical Demands of Each Role

Stockers often perform physically demanding tasks such as lifting heavy boxes, climbing ladders, and organizing shelves, requiring strength and stamina throughout their shifts. Replenishers focus on maintaining inventory levels, involving repetitive motions like unloading pallets and moving carts, which demands endurance and consistent pace. Both roles require proper ergonomics to prevent strain, but stockers generally face higher intensity physical labor due to heavier lifting and frequent mobility.

Career Growth Opportunities

Stocker roles primarily involve organizing and placing inventory on shelves, providing foundational skills essential for warehouse operations. Replenishers engage in restocking products to maintain optimal stock levels, often requiring greater coordination and inventory management expertise. Career growth opportunities favor replenishers, who can advance into supervisory or inventory control positions due to their involvement in critical supply chain tasks.

Salary and Benefits Overview

Stockers typically earn an average hourly wage ranging from $12 to $16, with entry-level positions offering basic benefits such as health insurance and paid time off. Replenishers often receive similar or slightly higher compensation, averaging $13 to $18 per hour, due to additional responsibilities related to inventory management. Comprehensive benefits packages for replenisher roles may include performance bonuses, retirement plans, and extended healthcare coverage, reflecting their critical role in maintaining supply chain efficiency.

Choosing the Right Path: Stocker or Replenisher

Choosing between a stocker and a replenisher role in warehousing depends on operational priorities; stockers focus on organizing and placing inventory efficiently to maximize storage space, while replenishers ensure continuous product availability by refilling picking locations. Understanding warehouse workflow and demand patterns helps determine which path aligns better with business goals. Opting for the right role enhances inventory accuracy, reduces stockouts, and improves overall warehouse productivity.

Stocker vs Replenisher Infographic

jobdiv.com

jobdiv.com