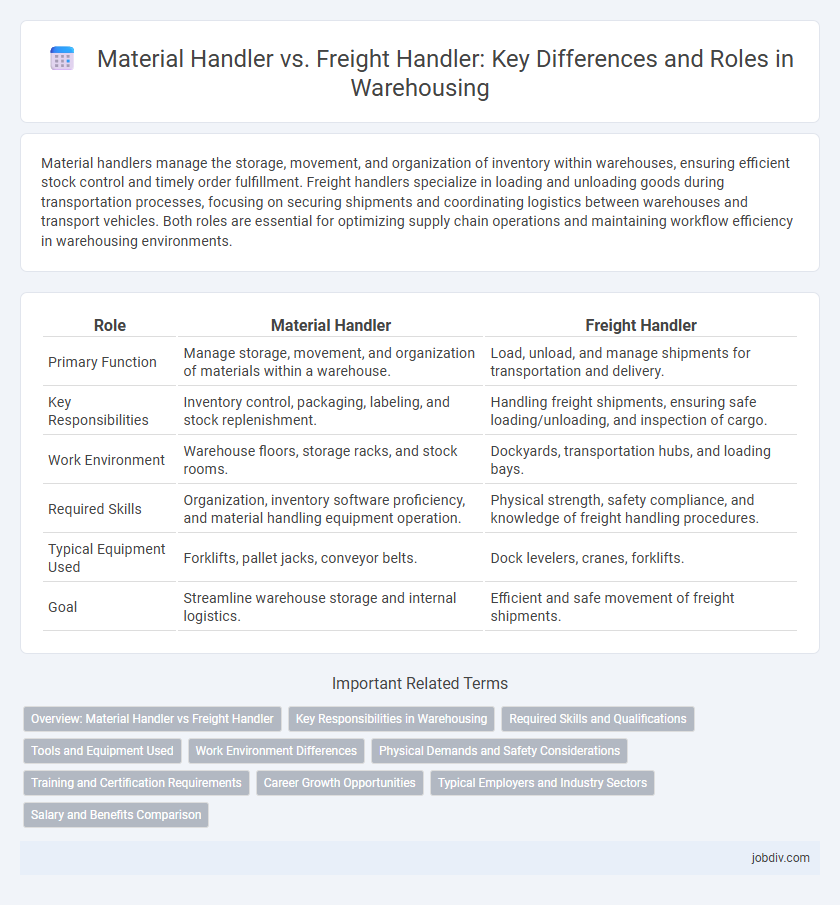

Material handlers manage the storage, movement, and organization of inventory within warehouses, ensuring efficient stock control and timely order fulfillment. Freight handlers specialize in loading and unloading goods during transportation processes, focusing on securing shipments and coordinating logistics between warehouses and transport vehicles. Both roles are essential for optimizing supply chain operations and maintaining workflow efficiency in warehousing environments.

Table of Comparison

| Role | Material Handler | Freight Handler |

|---|---|---|

| Primary Function | Manage storage, movement, and organization of materials within a warehouse. | Load, unload, and manage shipments for transportation and delivery. |

| Key Responsibilities | Inventory control, packaging, labeling, and stock replenishment. | Handling freight shipments, ensuring safe loading/unloading, and inspection of cargo. |

| Work Environment | Warehouse floors, storage racks, and stock rooms. | Dockyards, transportation hubs, and loading bays. |

| Required Skills | Organization, inventory software proficiency, and material handling equipment operation. | Physical strength, safety compliance, and knowledge of freight handling procedures. |

| Typical Equipment Used | Forklifts, pallet jacks, conveyor belts. | Dock levelers, cranes, forklifts. |

| Goal | Streamline warehouse storage and internal logistics. | Efficient and safe movement of freight shipments. |

Overview: Material Handler vs Freight Handler

Material handlers specialize in managing, moving, and storing raw materials and products within warehouses or production facilities, ensuring efficient inventory flow. Freight handlers focus on loading, unloading, and securing shipments during transport, working primarily at shipping docks or logistics hubs to facilitate smooth freight operations. Both roles are crucial for supply chain efficiency but differ in scope, with material handlers emphasizing inventory control and freight handlers concentrating on shipment handling.

Key Responsibilities in Warehousing

Material handlers in warehousing are primarily responsible for moving, storing, and organizing inventory within the facility, including loading and unloading goods, maintaining accurate inventory records, and ensuring the safe handling of materials. Freight handlers specialize in the loading, unloading, and securing of shipments on transportation vehicles, coordinating with carriers, and managing freight documentation to facilitate timely delivery. Both roles require adherence to safety protocols and efficient workflow management to optimize warehouse operations and supply chain logistics.

Required Skills and Qualifications

Material handlers require strong organizational skills, physical stamina, and proficiency with inventory management systems to efficiently move and manage goods within warehouses. Freight handlers must possess knowledge of loading and unloading procedures, forklift operation, and safety regulations to ensure the secure transportation of freight. Both roles benefit from attention to detail, basic mechanical skills, and the ability to work in fast-paced environments.

Tools and Equipment Used

Material handlers utilize tools such as forklifts, pallet jacks, conveyor belts, and hand trucks to efficiently manage inventory within warehouses. Freight handlers focus on equipment like loading docks, dock levelers, shrink wrap machines, and pallet stretchers to secure and transport shipments during loading and unloading processes. Both roles rely on protective gear such as gloves, steel-toe boots, and safety vests to ensure workplace safety.

Work Environment Differences

Material handlers typically operate within controlled warehouse environments, managing inventory, loading, and unloading goods with equipment such as forklifts and pallet jacks. Freight handlers work primarily in transportation hubs, loading and unloading freight from trucks, ships, or airplanes, often exposed to varying weather conditions and outdoor settings. The physical demands differ as material handlers have more access to safety protocols indoors, while freight handlers face rigorous manual labor in harsher, sometimes unpredictable environments.

Physical Demands and Safety Considerations

Material handlers endure significant physical demands, frequently lifting heavy loads, operating forklifts, and performing repetitive tasks that require strength and endurance in warehouse environments. Freight handlers face similar physical challenges but often work in shipping docks or transportation hubs, where the emphasis is on loading and unloading freight under time constraints and variable weather conditions. Safety considerations for both roles include proper ergonomic techniques, use of personal protective equipment (PPE), and adherence to OSHA guidelines to prevent workplace injuries such as musculoskeletal disorders and accidents related to heavy machinery.

Training and Certification Requirements

Material handlers typically require training in inventory management systems, forklift operation, and safety protocols, with certifications such as OSHA forklift certification and hazardous materials handling depending on the warehouse environment. Freight handlers focus more on the proper loading, unloading, and securing of goods, often needing certification in cargo handling and hazardous materials transportation regulations. Both roles emphasize safety training, but material handlers usually require more extensive certification related to warehouse equipment and inventory control systems.

Career Growth Opportunities

Material Handlers typically experience steady career growth through specialization in inventory management and logistics coordination, leading to roles such as warehouse supervisor or operations manager. Freight Handlers often advance by gaining expertise in freight logistics and transportation, enabling transitions into freight coordination or supply chain management positions. Both career paths benefit from continuous skills development in industry software and safety protocols, enhancing promotion prospects in the warehousing sector.

Typical Employers and Industry Sectors

Material handlers commonly find employment in manufacturing plants, distribution centers, and retail warehouses where they manage inventory and facilitate production flow. Freight handlers are typically employed by shipping companies, ports, and logistics firms specializing in the loading, unloading, and transportation of goods. Both roles play crucial parts in supply chain operations but serve distinct functions within sectors such as automotive, consumer goods, and e-commerce.

Salary and Benefits Comparison

Material handlers typically earn an average salary ranging from $30,000 to $45,000 annually, with benefits including health insurance, paid time off, and potential overtime pay. Freight handlers often receive slightly higher wages, approximately $32,000 to $50,000 per year, reflecting the physically demanding nature of loading and unloading cargo, accompanied by similar benefits and occasional bonuses for heavy-lift duties. Both roles offer opportunities for advancement in warehousing, with benefits packages that may vary by employer but generally include standard healthcare and retirement plans.

Material Handler vs Freight Handler Infographic

jobdiv.com

jobdiv.com