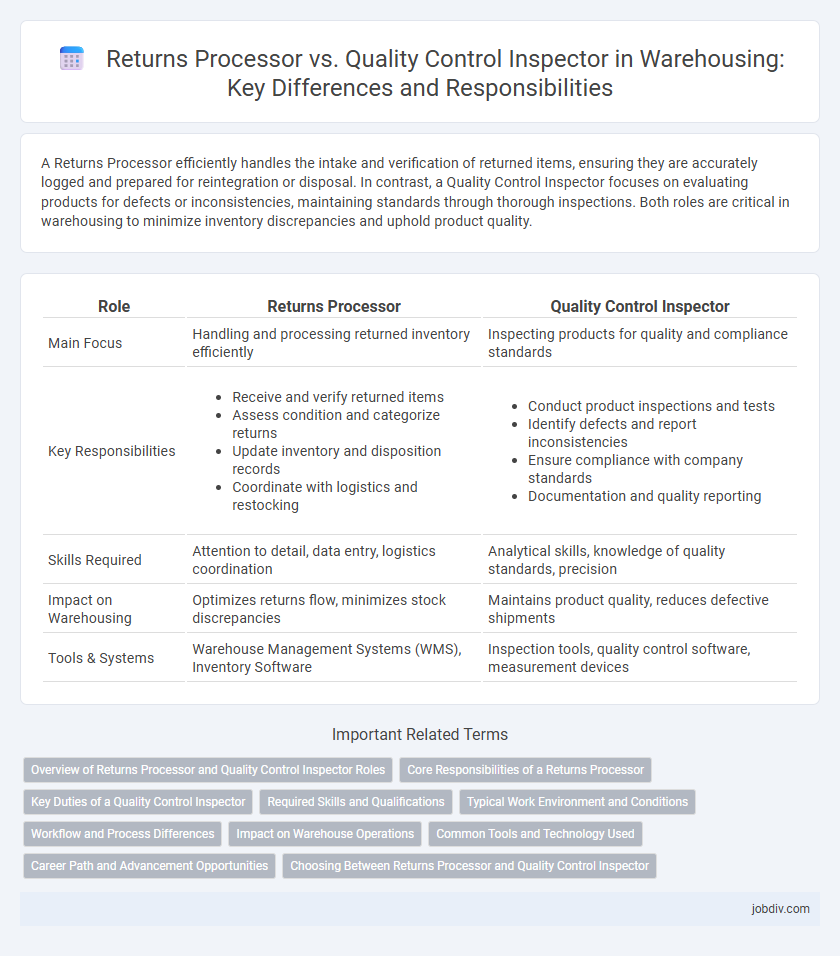

A Returns Processor efficiently handles the intake and verification of returned items, ensuring they are accurately logged and prepared for reintegration or disposal. In contrast, a Quality Control Inspector focuses on evaluating products for defects or inconsistencies, maintaining standards through thorough inspections. Both roles are critical in warehousing to minimize inventory discrepancies and uphold product quality.

Table of Comparison

| Role | Returns Processor | Quality Control Inspector |

|---|---|---|

| Main Focus | Handling and processing returned inventory efficiently | Inspecting products for quality and compliance standards |

| Key Responsibilities |

|

|

| Skills Required | Attention to detail, data entry, logistics coordination | Analytical skills, knowledge of quality standards, precision |

| Impact on Warehousing | Optimizes returns flow, minimizes stock discrepancies | Maintains product quality, reduces defective shipments |

| Tools & Systems | Warehouse Management Systems (WMS), Inventory Software | Inspection tools, quality control software, measurement devices |

Overview of Returns Processor and Quality Control Inspector Roles

A Returns Processor manages the intake, inspection, and restocking or disposal of returned products, ensuring accurate documentation and compliance with company policies. A Quality Control Inspector systematically examines incoming and outgoing inventory to detect defects, verify specifications, and maintain product standards. Both roles are vital in warehousing operations to optimize inventory accuracy and uphold customer satisfaction.

Core Responsibilities of a Returns Processor

A Returns Processor handles the intake, inspection, and documentation of returned merchandise, ensuring accurate restocking or disposal based on condition. Core responsibilities include verifying return authorization, assessing product condition against quality standards, and updating inventory systems accordingly. This role serves as a critical link between customer service and warehouse operations, aimed at minimizing losses and maintaining inventory accuracy.

Key Duties of a Quality Control Inspector

A Quality Control Inspector in warehousing is responsible for examining incoming and outgoing products to ensure compliance with quality standards, identifying defects, and reporting discrepancies. They meticulously conduct inspections, perform tests, and document results to maintain inventory integrity and reduce returned goods. Their role directly supports maintaining product quality, minimizing waste, and enhancing customer satisfaction through rigorous quality assurance processes.

Required Skills and Qualifications

A Returns Processor requires skills in inventory management, data entry accuracy, and proficiency with warehouse management systems to efficiently handle product returns and restocking processes. In contrast, a Quality Control Inspector must possess strong attention to detail, knowledge of quality standards, and expertise in inspection tools to identify defects and ensure compliance with company and regulatory requirements. Both roles demand physical stamina and effective communication skills, but the Quality Control Inspector typically requires specialized training or certification in quality assurance methodologies.

Typical Work Environment and Conditions

Returns Processors typically work in fast-paced warehouse settings where they handle incoming returned goods, often standing for long periods and operating conveyor systems and scanning devices. Quality Control Inspectors operate in controlled environments focused on detailed inspection of products, requiring attention to cleanliness and precision to identify defects or inconsistencies. Both roles may involve exposure to varying temperatures and require adherence to safety protocols, but Returns Processors often face higher physical demands related to material handling.

Workflow and Process Differences

Returns Processors handle the reception, sorting, and restocking of returned products by verifying item conditions and updating inventory records. Quality Control Inspectors focus on inspecting items for defects or damages through detailed quality assessments, often halting flawed products from re-entering the supply chain. The workflow of Returns Processors prioritizes efficient item processing and data entry, while Quality Control Inspectors emphasize thorough inspection protocols and compliance with quality standards.

Impact on Warehouse Operations

Returns Processors streamline warehouse operations by efficiently managing incoming returned goods, minimizing processing time and reducing storage congestion. Quality Control Inspectors enhance operational accuracy by identifying defects or inconsistencies early, preventing defective inventory from re-entering the supply chain and ensuring customer satisfaction. Both roles collectively improve inventory accuracy, reduce operational delays, and optimize overall warehouse productivity.

Common Tools and Technology Used

Returns Processors and Quality Control Inspectors both utilize barcode scanners, warehouse management systems (WMS), and inventory tracking software to streamline operations. Returns Processors focus on tools like return merchandise authorization (RMA) systems and automated sorting equipment to efficiently handle returned items. Quality Control Inspectors rely on inspection devices such as digital calipers, moisture meters, and defect detection software to ensure products meet quality standards.

Career Path and Advancement Opportunities

Returns processors typically begin their careers handling product inspections and sorting returns, gaining foundational knowledge of inventory management and warehouse operations. Quality control inspectors build on this experience by specializing in evaluating product standards, often advancing to supervisory roles that involve developing quality assurance protocols and leading inspection teams. Career advancement in returns processing may lead to warehouse management, while quality control inspectors often progress into higher-level quality assurance management or regulatory compliance positions.

Choosing Between Returns Processor and Quality Control Inspector

Choosing between a Returns Processor and a Quality Control Inspector depends on the core operational priorities within warehousing. A Returns Processor specializes in efficiently managing returned goods, ensuring accurate documentation and timely reintegration into inventory. In contrast, a Quality Control Inspector focuses on verifying product standards and identifying defects, which is crucial for maintaining overall inventory quality and reducing downstream issues.

Returns Processor vs Quality Control Inspector Infographic

jobdiv.com

jobdiv.com