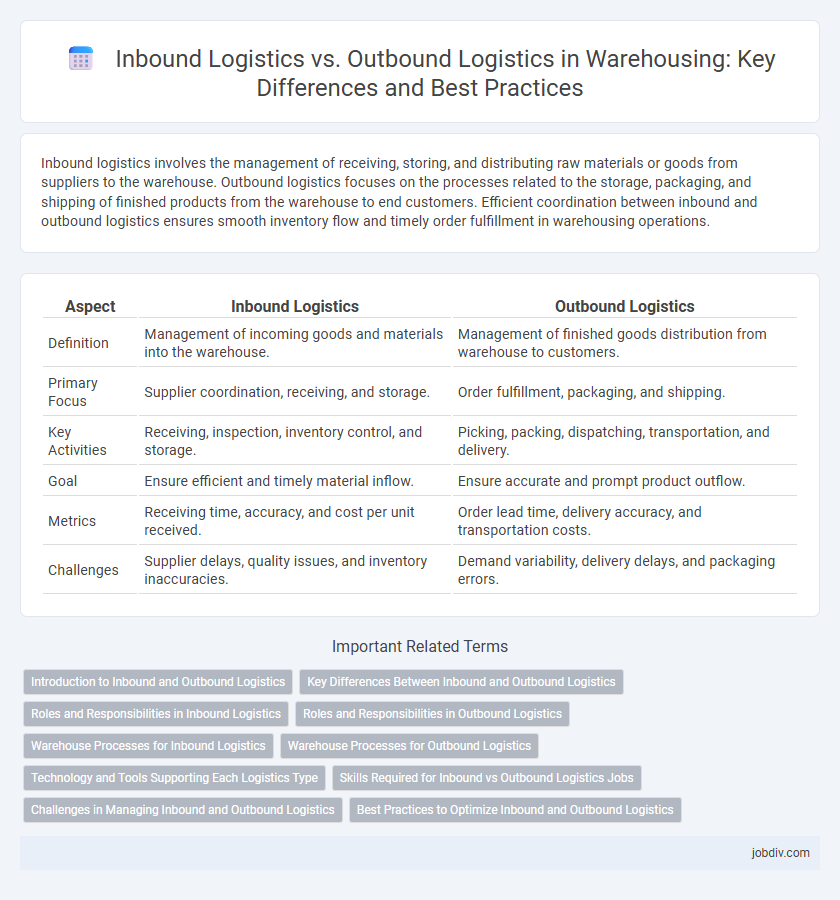

Inbound logistics involves the management of receiving, storing, and distributing raw materials or goods from suppliers to the warehouse. Outbound logistics focuses on the processes related to the storage, packaging, and shipping of finished products from the warehouse to end customers. Efficient coordination between inbound and outbound logistics ensures smooth inventory flow and timely order fulfillment in warehousing operations.

Table of Comparison

| Aspect | Inbound Logistics | Outbound Logistics |

|---|---|---|

| Definition | Management of incoming goods and materials into the warehouse. | Management of finished goods distribution from warehouse to customers. |

| Primary Focus | Supplier coordination, receiving, and storage. | Order fulfillment, packaging, and shipping. |

| Key Activities | Receiving, inspection, inventory control, and storage. | Picking, packing, dispatching, transportation, and delivery. |

| Goal | Ensure efficient and timely material inflow. | Ensure accurate and prompt product outflow. |

| Metrics | Receiving time, accuracy, and cost per unit received. | Order lead time, delivery accuracy, and transportation costs. |

| Challenges | Supplier delays, quality issues, and inventory inaccuracies. | Demand variability, delivery delays, and packaging errors. |

Introduction to Inbound and Outbound Logistics

Inbound logistics involves the transportation, storage, and receipt of incoming goods and materials from suppliers to the warehouse. Outbound logistics focuses on the distribution, packaging, and delivery of finished products from the warehouse to customers or retailers. Both are critical components in optimizing supply chain efficiency and reducing overall operational costs.

Key Differences Between Inbound and Outbound Logistics

Inbound logistics involves the transportation, storage, and receipt of goods entering a warehouse, focusing on supplier coordination, inventory management, and quality control. Outbound logistics centers on the distribution and delivery of finished products to customers, emphasizing order fulfillment, packaging, and shipping accuracy. Key differences include the direction of goods flow, with inbound logistics managing supply acquisition and outbound logistics handling product distribution.

Roles and Responsibilities in Inbound Logistics

Inbound logistics encompasses the coordination and management of receiving, handling, and storing materials from suppliers to warehouses, ensuring timely and accurate delivery of raw materials or products. Key roles include inventory control specialists, warehouse managers, and receiving clerks who verify shipments, conduct quality inspections, and maintain storage organization. Efficient inbound logistics supports production schedules and overall supply chain effectiveness by minimizing delays and optimizing resource allocation.

Roles and Responsibilities in Outbound Logistics

Outbound logistics involves managing the storage, transportation, and distribution of finished goods from the warehouse to the end customer or retail locations. Key roles include order picking, packing, scheduling shipments, managing transportation carriers, and ensuring timely delivery to meet customer demands. Responsibilities also encompass inventory control, quality checks, documentation, and coordination with sales and customer service teams to optimize the supply chain flow.

Warehouse Processes for Inbound Logistics

Inbound logistics in warehousing involves receiving, inspecting, and storing incoming goods efficiently to ensure seamless inventory management. Key processes include unloading shipments, verifying order accuracy, quality control, and organizing stock within designated storage locations using warehouse management systems (WMS). Optimizing these steps reduces handling time, minimizes errors, and supports timely availability of products for downstream operations.

Warehouse Processes for Outbound Logistics

Warehouse processes for outbound logistics involve order picking, packing, and shipping to ensure timely delivery of goods to customers. Efficient inventory management and real-time tracking systems optimize the flow of products from storage to transportation vehicles. Automation technologies like conveyor belts and warehouse management software reduce errors and enhance throughput in outbound operations.

Technology and Tools Supporting Each Logistics Type

Inbound logistics leverage advanced warehouse management systems (WMS), automated receiving docks, and RFID technology to streamline inventory tracking and improve supplier coordination. Outbound logistics utilize transportation management systems (TMS), order fulfillment software, and real-time delivery tracking tools to optimize route planning and enhance customer satisfaction. Both logistics types increasingly integrate IoT devices and AI-powered analytics to boost efficiency and reduce operational costs.

Skills Required for Inbound vs Outbound Logistics Jobs

Inbound logistics jobs demand skills in inventory management, quality control, and supplier coordination to ensure efficient receipt and storage of goods. Outbound logistics roles require expertise in order fulfillment, distribution planning, and customer communication to guarantee timely delivery and accurate shipping. Both positions benefit from strong analytical abilities and proficiency with warehouse management systems (WMS) to optimize operational workflows.

Challenges in Managing Inbound and Outbound Logistics

Managing inbound logistics challenges involves coordinating supplier deliveries, optimizing receiving processes, and ensuring accurate inventory intake to prevent delays and stock discrepancies. Outbound logistics requires efficient order fulfillment, timely shipping, and managing last-mile delivery complexities to maintain customer satisfaction and reduce transportation costs. Both inbound and outbound logistics face hurdles in real-time tracking, demand variability, and resource allocation, necessitating integrated warehouse management systems for streamlined operations.

Best Practices to Optimize Inbound and Outbound Logistics

Efficient inbound logistics relies on strategic supplier coordination, accurate demand forecasting, and real-time inventory tracking to minimize delays and reduce excess stock. Outbound logistics optimization focuses on route planning, timely order fulfillment, and leveraging technology such as warehouse management systems (WMS) to enhance delivery accuracy and customer satisfaction. Integrating cross-docking and automated sorting systems improves overall warehouse flow, reducing handling times and operational costs in both inbound and outbound processes.

Inbound Logistics vs Outbound Logistics Infographic

jobdiv.com

jobdiv.com