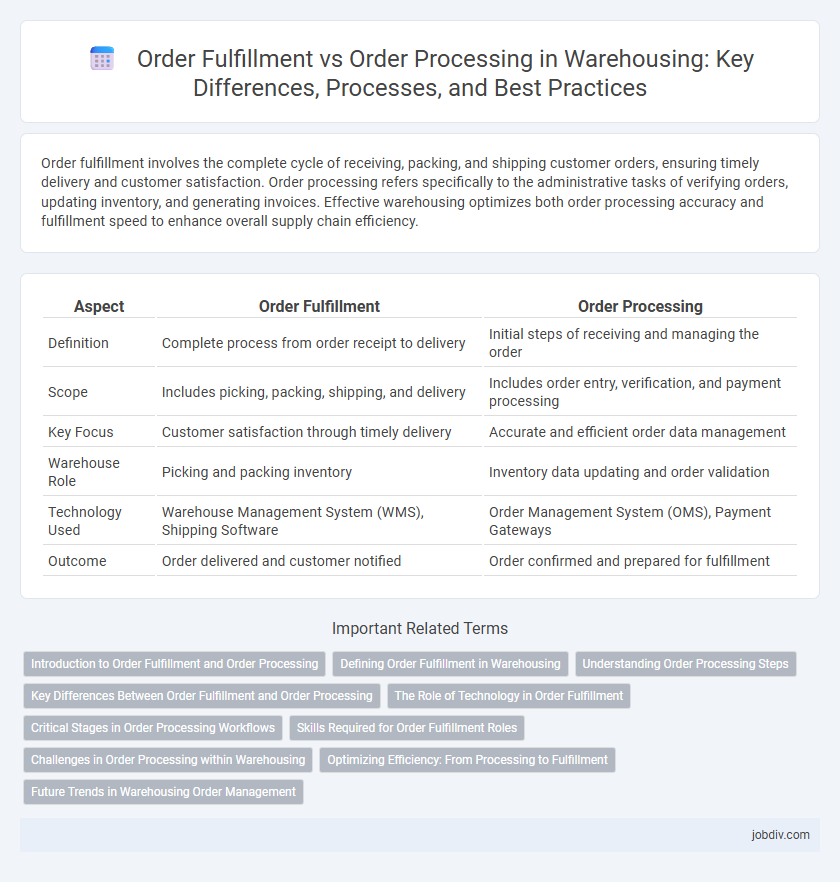

Order fulfillment involves the complete cycle of receiving, packing, and shipping customer orders, ensuring timely delivery and customer satisfaction. Order processing refers specifically to the administrative tasks of verifying orders, updating inventory, and generating invoices. Effective warehousing optimizes both order processing accuracy and fulfillment speed to enhance overall supply chain efficiency.

Table of Comparison

| Aspect | Order Fulfillment | Order Processing |

|---|---|---|

| Definition | Complete process from order receipt to delivery | Initial steps of receiving and managing the order |

| Scope | Includes picking, packing, shipping, and delivery | Includes order entry, verification, and payment processing |

| Key Focus | Customer satisfaction through timely delivery | Accurate and efficient order data management |

| Warehouse Role | Picking and packing inventory | Inventory data updating and order validation |

| Technology Used | Warehouse Management System (WMS), Shipping Software | Order Management System (OMS), Payment Gateways |

| Outcome | Order delivered and customer notified | Order confirmed and prepared for fulfillment |

Introduction to Order Fulfillment and Order Processing

Order fulfillment encompasses the entire process of receiving, handling, packing, and shipping customer orders to ensure timely delivery. Order processing refers specifically to the steps taken to verify and prepare an order for fulfillment, including order entry, inventory allocation, and payment confirmation. Efficient coordination between order processing and fulfillment optimizes warehouse operations and enhances customer satisfaction.

Defining Order Fulfillment in Warehousing

Order fulfillment in warehousing refers to the complete process of receiving, picking, packing, and shipping customer orders efficiently and accurately. It involves inventory management, warehouse layout optimization, and real-time tracking to ensure timely delivery and reduce errors. Effective order fulfillment enhances customer satisfaction by streamlining operations from order receipt to final delivery.

Understanding Order Processing Steps

Order processing in warehousing involves a series of critical steps including order receipt, order picking, packing, and shipping to ensure accurate and timely delivery. This process directly impacts inventory management, customer satisfaction, and operational efficiency by minimizing errors and fulfillment delays. Streamlining these steps through automation and real-time tracking enhances overall supply chain performance and reduces order cycle times.

Key Differences Between Order Fulfillment and Order Processing

Order fulfillment involves the complete workflow from receiving, packaging, and shipping a customer's order, while order processing primarily focuses on handling the order details such as verification, payment authorization, and inventory checks. Key differences include order fulfillment's logistics and delivery responsibilities versus order processing's administrative tasks in managing order accuracy and order entry. Efficient coordination between both processes streamlines warehouse operations, improves customer satisfaction, and reduces order cycle time.

The Role of Technology in Order Fulfillment

Technology accelerates order fulfillment by automating inventory management, barcode scanning, and real-time tracking, ensuring faster and more accurate deliveries. Advanced warehouse management systems (WMS) integrate seamlessly with order processing software to synchronize picking, packing, and shipping operations. Robotics and AI-driven algorithms optimize route planning and inventory allocation, reducing fulfillment errors and enhancing customer satisfaction.

Critical Stages in Order Processing Workflows

Order processing workflows encompass critical stages such as order entry, inventory verification, payment authorization, and order picking, which directly impact overall order fulfillment efficiency. Accurate data capture during order entry and real-time inventory management are essential to prevent stockouts and delays. Streamlining these stages with automation technologies enhances accuracy and accelerates the transition from order processing to fulfillment.

Skills Required for Order Fulfillment Roles

Order fulfillment roles demand skills in inventory management, accurate picking and packing, and proficiency with warehouse management systems (WMS) to ensure timely and error-free shipments. Strong attention to detail and the ability to operate material handling equipment like forklifts or barcode scanners are essential for maintaining order accuracy and operational efficiency. Effective communication and coordination skills are crucial for collaborating with cross-functional teams to meet delivery deadlines and customer satisfaction goals.

Challenges in Order Processing within Warehousing

Order processing in warehousing faces significant challenges such as inventory inaccuracies, which lead to picking errors and delays. Complex order customization increases the difficulty of accurately assembling and packaging items, resulting in higher labor costs and time consumption. Inefficient communication between warehouse management systems and order management platforms often causes synchronization issues, impairing real-time order tracking and fulfillment accuracy.

Optimizing Efficiency: From Processing to Fulfillment

Order processing involves receiving, verifying, and entering customer orders into the warehouse system, setting the stage for efficient inventory management and timely fulfillment. Streamlining order fulfillment focuses on picking, packing, and shipping products accurately to meet delivery deadlines and enhance customer satisfaction. Integrating advanced warehouse management systems (WMS) with automation technologies optimizes efficiency by reducing errors, minimizing delays, and improving overall supply chain performance.

Future Trends in Warehousing Order Management

Future trends in warehousing order management emphasize automation and real-time data integration to enhance both order fulfillment and order processing accuracy. Advanced AI-driven systems optimize inventory allocation and predictive demand forecasting, reducing lead times and operational costs. The adoption of robotics and IoT technologies streamlines workflows, ensuring seamless coordination between order receipt, picking, packing, and shipping processes.

Order Fulfillment vs Order Processing Infographic

jobdiv.com

jobdiv.com