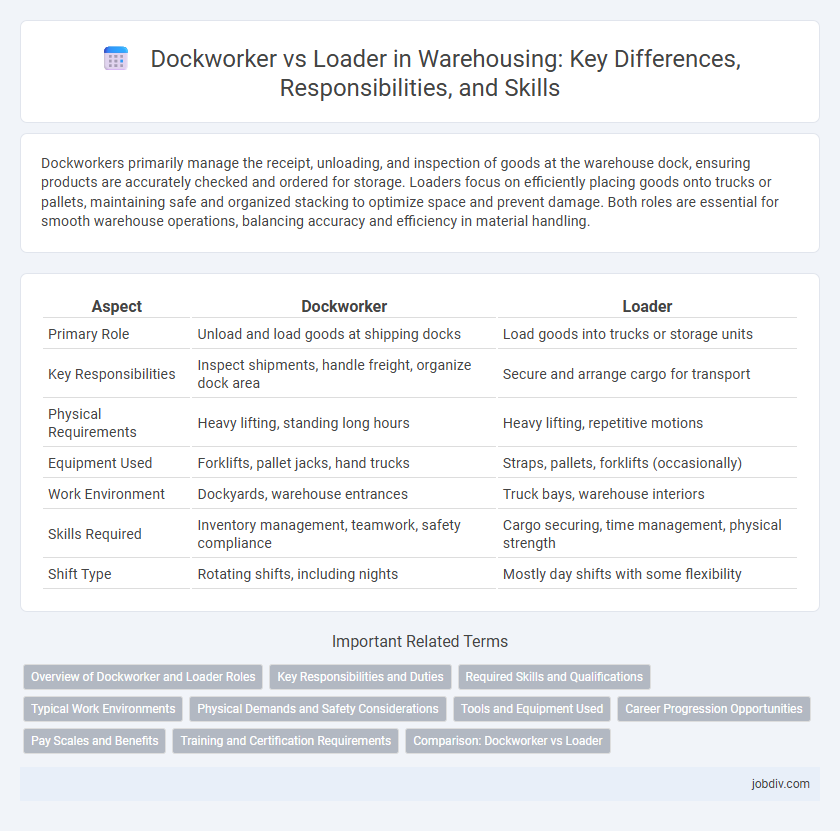

Dockworkers primarily manage the receipt, unloading, and inspection of goods at the warehouse dock, ensuring products are accurately checked and ordered for storage. Loaders focus on efficiently placing goods onto trucks or pallets, maintaining safe and organized stacking to optimize space and prevent damage. Both roles are essential for smooth warehouse operations, balancing accuracy and efficiency in material handling.

Table of Comparison

| Aspect | Dockworker | Loader |

|---|---|---|

| Primary Role | Unload and load goods at shipping docks | Load goods into trucks or storage units |

| Key Responsibilities | Inspect shipments, handle freight, organize dock area | Secure and arrange cargo for transport |

| Physical Requirements | Heavy lifting, standing long hours | Heavy lifting, repetitive motions |

| Equipment Used | Forklifts, pallet jacks, hand trucks | Straps, pallets, forklifts (occasionally) |

| Work Environment | Dockyards, warehouse entrances | Truck bays, warehouse interiors |

| Skills Required | Inventory management, teamwork, safety compliance | Cargo securing, time management, physical strength |

| Shift Type | Rotating shifts, including nights | Mostly day shifts with some flexibility |

Overview of Dockworker and Loader Roles

Dockworkers specialize in managing cargo at shipping docks, ensuring efficient loading and unloading of goods from ships, trucks, and trains, while adhering to safety protocols. Loaders focus primarily on placing, stacking, and securing items within warehouses or transportation vehicles to optimize space and prevent damage during transit. Both roles require physical stamina and knowledge of material handling equipment, but dockworkers often engage more with external freight movement, whereas loaders concentrate on internal warehouse organization.

Key Responsibilities and Duties

Dockworkers specialize in unloading and loading goods at shipping docks, ensuring cargo is handled safely and organized efficiently for transportation. Loaders focus primarily on placing products onto trucks or pallets, maintaining proper alignment and weight distribution to prevent damage during transit. Both roles emphasize physical labor and adherence to safety protocols but differ in their operational settings and the scope of material handling tasks.

Required Skills and Qualifications

Dockworkers require strong physical stamina, excellent coordination, and knowledge of safety protocols to efficiently handle loading and unloading tasks. Loaders must possess basic mechanical skills, attention to detail, and the ability to operate forklifts or pallet jacks, often necessitating certification or training. Both roles demand teamwork, time management, and adherence to warehouse operational standards to ensure smooth inventory flow.

Typical Work Environments

Dockworkers typically operate in large shipping ports, warehouses, and distribution centers where they handle the loading and unloading of cargo from ships, trucks, and trains, often exposed to outdoor elements. Loaders generally work inside warehouses or retail facilities, focusing on moving goods onto pallets, shelves, or delivery vehicles within controlled indoor settings. Both roles demand physical labor, but dockworkers face more variable and often harsher environmental conditions compared to the generally stable and climate-controlled environments loaders experience.

Physical Demands and Safety Considerations

Dockworkers face intense physical demands including heavy lifting, prolonged standing, and operating large machinery, requiring high endurance and strength. Loaders engage in repetitive movements such as bending and lifting, often under tight time constraints, increasing risk of musculoskeletal injuries. Safety considerations for both roles emphasize ergonomic training, proper use of personal protective equipment (PPE), and adherence to warehouse safety protocols to minimize workplace accidents.

Tools and Equipment Used

Dockworkers primarily utilize pallet jacks, forklifts, and conveyor belts to efficiently move and organize cargo within warehouse docks. Loaders rely on equipment such as loading ramps, hand trucks, and specialized lift gates to safely transfer goods between transport vehicles and storage areas. Both roles emphasize the use of safety gear including gloves, steel-toed boots, and high-visibility vests to maintain workplace safety during material handling operations.

Career Progression Opportunities

Dockworkers often start with physically demanding roles focused on loading and unloading shipments but can advance to supervisory or logistics coordinator positions by developing skills in inventory management and safety protocols. Loaders typically have entry-level responsibilities but can progress to roles such as material handler or warehouse technician by gaining expertise in equipment operation and efficient loading techniques. Career growth in both positions depends heavily on acquiring certifications, understanding supply chain processes, and demonstrating reliability and teamwork.

Pay Scales and Benefits

Dockworkers typically earn higher pay scales than loaders due to specialized skills in operating heavy machinery and managing logistics. Loaders often receive hourly wages that are lower but may benefit from entry-level accessibility and training opportunities. Both positions frequently qualify for benefits such as health insurance, retirement plans, and overtime pay, though dockworkers usually access more comprehensive packages.

Training and Certification Requirements

Dockworkers typically require comprehensive training in safety protocols, heavy equipment operation, and hazardous materials handling, often obtaining certifications such as OSHA Forklift Operator or HAZMAT Awareness. Loaders generally need less formal training but must be skilled in efficient cargo handling and may receive on-the-job instruction or certifications related to specific loading machinery. Both roles prioritize safety compliance, yet dockworkers face more stringent certification demands due to the complexity and risks associated with their tasks.

Comparison: Dockworker vs Loader

Dockworkers primarily manage the loading and unloading of goods at shipping docks, ensuring the safe handling and storage of inventory, while loaders focus on placing, securing, and moving goods within warehouses or transport vehicles. Dockworkers often operate heavy machinery like forklifts and coordinate with logistics teams for timely shipments, whereas loaders emphasize physical labor and accurate placement to maintain order and efficiency in storage areas. Both roles are critical in supply chain operations, but dockworkers have broader responsibilities involving inventory management and equipment operation compared to the manual and task-specific duties of loaders.

Dockworker vs Loader Infographic

jobdiv.com

jobdiv.com