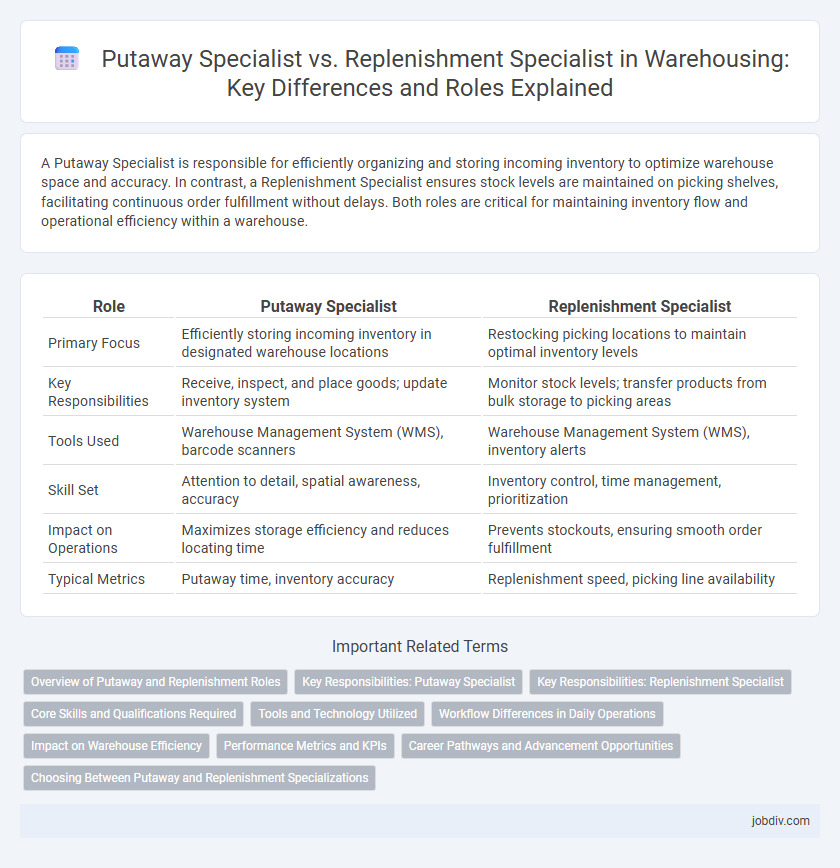

A Putaway Specialist is responsible for efficiently organizing and storing incoming inventory to optimize warehouse space and accuracy. In contrast, a Replenishment Specialist ensures stock levels are maintained on picking shelves, facilitating continuous order fulfillment without delays. Both roles are critical for maintaining inventory flow and operational efficiency within a warehouse.

Table of Comparison

| Role | Putaway Specialist | Replenishment Specialist |

|---|---|---|

| Primary Focus | Efficiently storing incoming inventory in designated warehouse locations | Restocking picking locations to maintain optimal inventory levels |

| Key Responsibilities | Receive, inspect, and place goods; update inventory system | Monitor stock levels; transfer products from bulk storage to picking areas |

| Tools Used | Warehouse Management System (WMS), barcode scanners | Warehouse Management System (WMS), inventory alerts |

| Skill Set | Attention to detail, spatial awareness, accuracy | Inventory control, time management, prioritization |

| Impact on Operations | Maximizes storage efficiency and reduces locating time | Prevents stockouts, ensuring smooth order fulfillment |

| Typical Metrics | Putaway time, inventory accuracy | Replenishment speed, picking line availability |

Overview of Putaway and Replenishment Roles

Putaway Specialists efficiently organize and store incoming inventory in designated warehouse locations to maximize space utilization and ensure easy accessibility. Replenishment Specialists focus on maintaining optimal stock levels on picking shelves to prevent order delays and support continuous warehouse operations. Both roles are critical for inventory accuracy and operational efficiency in modern warehouse management systems.

Key Responsibilities: Putaway Specialist

Putaway Specialists are responsible for accurately receiving, inspecting, and storing incoming inventory in designated warehouse locations to optimize space utilization and inventory accessibility. They utilize warehouse management systems (WMS) to update stock locations and ensure items are stored according to safety and organizational standards. Maintaining warehouse orderliness and performing regular cycle counts to prevent discrepancies also fall under their critical duties.

Key Responsibilities: Replenishment Specialist

Replenishment Specialists focus on maintaining optimal inventory levels by systematically restocking warehouse shelves based on demand forecasts and sales data. They monitor stock movement patterns, coordinate with procurement and receiving teams to ensure timely availability of products, and prioritize high-turnover items to minimize stockouts. Their role is critical in supporting continuous order fulfillment and improving overall warehouse efficiency.

Core Skills and Qualifications Required

Putaway Specialists require strong spatial awareness, inventory management skills, and proficiency with warehouse management systems (WMS) to accurately store incoming goods in designated locations. Replenishment Specialists focus on demand forecasting, stock level monitoring, and timely restocking to ensure continuous product availability on the warehouse floor. Both roles demand attention to detail, physical stamina, and knowledge of safety protocols to maintain efficient warehouse operations.

Tools and Technology Utilized

Putaway Specialists primarily utilize inventory management systems (IMS) and barcode scanners to efficiently organize and store incoming goods in designated warehouse locations. Replenishment Specialists rely heavily on automated replenishment software and real-time stock tracking tools to ensure optimal inventory levels on the warehouse floor. Both roles leverage warehouse management systems (WMS) to coordinate tasks, but Putaway Specialists focus on spatial data optimization, while Replenishment Specialists prioritize demand forecasting and order accuracy.

Workflow Differences in Daily Operations

Putaway Specialists focus on efficiently locating and storing incoming inventory in designated warehouse locations, ensuring accurate scanning and placement to optimize space utilization. Replenishment Specialists prioritize monitoring stock levels on picking shelves and restocking items from bulk storage to maintain continuous order fulfillment. Their workflows differ as Putaway involves initial product receipt and storage, while Replenishment centers on sustaining inventory availability for ongoing picking processes.

Impact on Warehouse Efficiency

Putaway Specialists optimize warehouse space utilization by systematically storing incoming inventory in designated locations, reducing retrieval times and minimizing misplacement errors. Replenishment Specialists maintain inventory levels on picking shelves, ensuring continuous availability of products to prevent order fulfillment delays. Together, these roles significantly enhance warehouse efficiency by streamlining inventory flow and supporting faster order processing cycles.

Performance Metrics and KPIs

Putaway Specialists are primarily evaluated on metrics such as putaway accuracy rate, time-to-putaway, and the number of items correctly stored per hour, which measure their efficiency and precision in organizing inventory. Replenishment Specialists focus on KPIs like stockout rates, replenishment cycle time, and order fulfillment speed, reflecting their role in maintaining optimal inventory levels and ensuring smooth order processing. Both roles impact overall warehouse productivity but emphasize different performance indicators aligned with their specific operational responsibilities.

Career Pathways and Advancement Opportunities

Putaway Specialists develop expertise in inventory management and spatial organization, paving the way for advancement into warehouse supervisory roles or logistics coordination. Replenishment Specialists gain deep knowledge of stock levels and demand forecasting, which often leads to careers in inventory control or supply chain management. Both paths offer strong foundations for progression in warehouse operations and supply chain leadership positions.

Choosing Between Putaway and Replenishment Specializations

Choosing between a Putaway Specialist and a Replenishment Specialist depends on warehouse operational priorities such as inventory accuracy and stock availability. Putaway Specialists excel in efficiently storing incoming goods, optimizing space utilization, and ensuring systematic organization for quick retrieval. Replenishment Specialists focus on maintaining optimal stock levels in picking locations to reduce stockouts, enhance order fulfillment speed, and support continuous production flow.

Putaway Specialist vs Replenishment Specialist Infographic

jobdiv.com

jobdiv.com