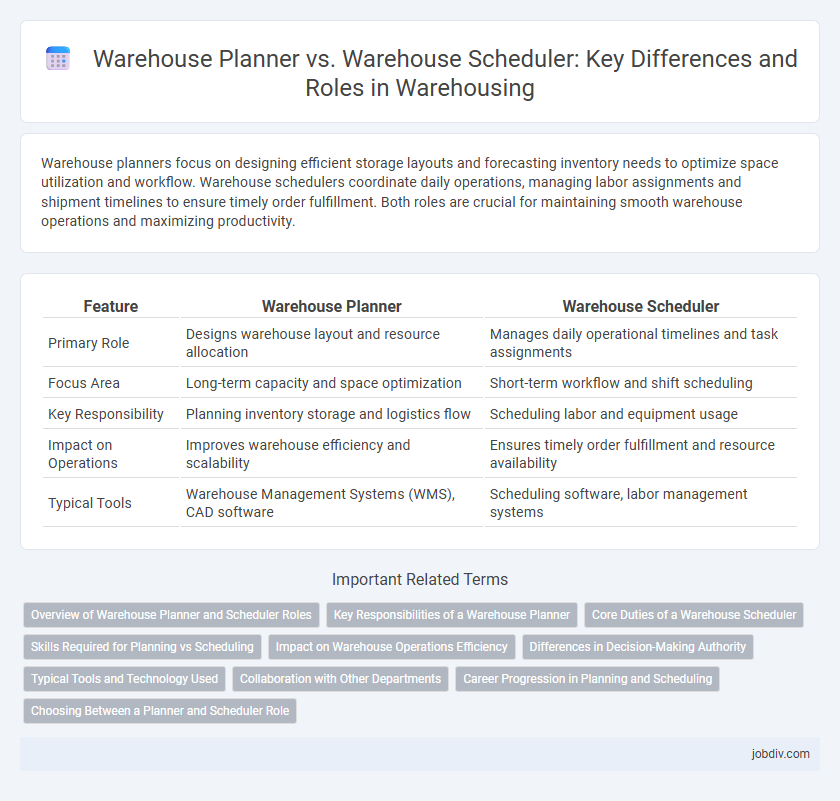

Warehouse planners focus on designing efficient storage layouts and forecasting inventory needs to optimize space utilization and workflow. Warehouse schedulers coordinate daily operations, managing labor assignments and shipment timelines to ensure timely order fulfillment. Both roles are crucial for maintaining smooth warehouse operations and maximizing productivity.

Table of Comparison

| Feature | Warehouse Planner | Warehouse Scheduler |

|---|---|---|

| Primary Role | Designs warehouse layout and resource allocation | Manages daily operational timelines and task assignments |

| Focus Area | Long-term capacity and space optimization | Short-term workflow and shift scheduling |

| Key Responsibility | Planning inventory storage and logistics flow | Scheduling labor and equipment usage |

| Impact on Operations | Improves warehouse efficiency and scalability | Ensures timely order fulfillment and resource availability |

| Typical Tools | Warehouse Management Systems (WMS), CAD software | Scheduling software, labor management systems |

Overview of Warehouse Planner and Scheduler Roles

Warehouse planners focus on designing efficient warehouse layouts and optimizing inventory placement to enhance space utilization and reduce handling time. Warehouse schedulers coordinate the timing of inbound and outbound shipments, ensuring smooth workflow and timely order fulfillment. Both roles are critical for maintaining operational efficiency and meeting logistics targets in warehousing management.

Key Responsibilities of a Warehouse Planner

A Warehouse Planner is responsible for designing efficient storage layouts, forecasting inventory requirements, and coordinating materials flow to optimize space utilization and minimize handling costs. They analyze demand patterns and lead time to develop replenishment strategies, ensuring timely stock availability and reducing excess inventory. Their role includes collaborating with procurement, production, and logistics teams to align warehouse capacity with overall supply chain objectives.

Core Duties of a Warehouse Scheduler

A Warehouse Scheduler primarily focuses on optimizing daily and weekly workflows by managing shipment timelines, coordinating inbound and outbound deliveries, and ensuring adherence to production schedules. They utilize advanced scheduling software and real-time data analytics to allocate resources efficiently and minimize operational bottlenecks. Unlike a Warehouse Planner who develops long-term strategies for inventory management and warehouse layout, the scheduler's core duties revolve around the immediate sequencing of tasks to maintain seamless warehouse operations.

Skills Required for Planning vs Scheduling

Warehouse planners require strong analytical skills, proficiency in inventory management software, and the ability to forecast demand accurately to optimize storage and resource allocation. Warehouse schedulers need excellent time management, communication abilities, and expertise in coordinating labor and equipment schedules to ensure timely order fulfillment. Both roles demand attention to detail and problem-solving capabilities, but planners focus more on strategic resource planning while schedulers emphasize operational execution.

Impact on Warehouse Operations Efficiency

Warehouse planners optimize storage layout and inventory flow, enhancing space utilization and reducing retrieval times. Warehouse schedulers coordinate the timing of inbound and outbound shipments, ensuring resources are allocated efficiently and minimizing downtime. Together, they significantly improve warehouse operations efficiency by balancing strategic planning with real-time execution.

Differences in Decision-Making Authority

Warehouse planners hold strategic decision-making authority, focusing on long-term inventory management, space allocation, and workflow optimization to ensure operational efficiency. Warehouse schedulers primarily exercise tactical decision-making authority, managing daily task assignments, labor allocation, and shipment timings to meet short-term operational goals. The distinction in decision-making authority highlights planners' role in overarching warehousing strategies versus schedulers' focus on implementing those strategies through day-to-day scheduling.

Typical Tools and Technology Used

Warehouse planners typically utilize advanced inventory management systems (IMS), demand forecasting software, and 3D space optimization tools to design efficient storage layouts and coordinate stock levels. Warehouse schedulers rely on transportation management systems (TMS), real-time labor scheduling software, and order management platforms to allocate resources and streamline operational workflows. Both roles leverage RFID scanning technology and warehouse execution systems (WES) to enhance accuracy and productivity within distribution centers.

Collaboration with Other Departments

Warehouse planners collaborate closely with procurement and inventory management teams to forecast demand and optimize stock levels, ensuring timely replenishment and storage efficiency. Warehouse schedulers coordinate with logistics, transportation, and production departments to align receiving, order fulfillment, and shipping schedules, minimizing delays and enhancing throughput. Both roles require seamless communication across sales, customer service, and supply chain teams to synchronize operations and improve overall warehouse performance.

Career Progression in Planning and Scheduling

Warehouse planner roles focus on strategic inventory optimization, layout design, and resource allocation to improve overall warehouse efficiency. Warehouse schedulers concentrate on day-to-day task assignments, shift planning, and workflow coordination to meet operational deadlines. Career progression often advances from scheduler to planner, expanding responsibilities from tactical execution to strategic planning, ultimately leading to management positions within logistics and supply chain operations.

Choosing Between a Planner and Scheduler Role

Warehouse planners focus on strategic layout optimization, inventory forecasting, and resource allocation to ensure efficient warehouse operations. Warehouse schedulers concentrate on day-to-day task assignments, shift planning, and coordinating inbound and outbound shipments for timely execution. Choosing between a planner and scheduler depends on whether the priority is long-term operational efficiency or immediate workforce and shipment coordination.

Warehouse Planner vs Warehouse Scheduler Infographic

jobdiv.com

jobdiv.com