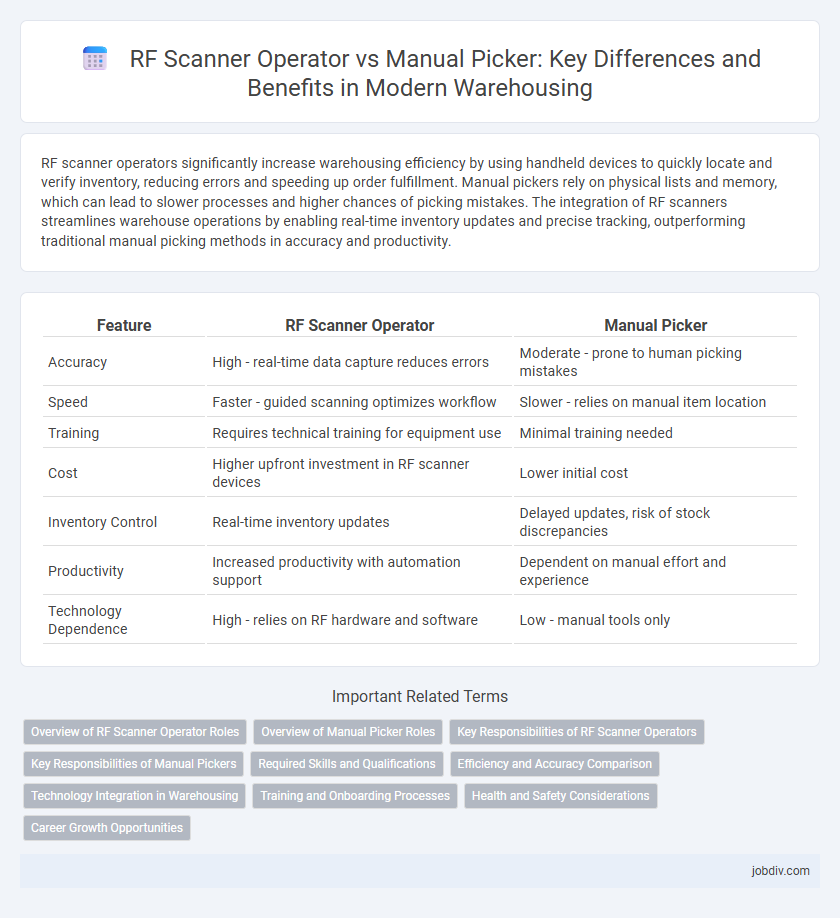

RF scanner operators significantly increase warehousing efficiency by using handheld devices to quickly locate and verify inventory, reducing errors and speeding up order fulfillment. Manual pickers rely on physical lists and memory, which can lead to slower processes and higher chances of picking mistakes. The integration of RF scanners streamlines warehouse operations by enabling real-time inventory updates and precise tracking, outperforming traditional manual picking methods in accuracy and productivity.

Table of Comparison

| Feature | RF Scanner Operator | Manual Picker |

|---|---|---|

| Accuracy | High - real-time data capture reduces errors | Moderate - prone to human picking mistakes |

| Speed | Faster - guided scanning optimizes workflow | Slower - relies on manual item location |

| Training | Requires technical training for equipment use | Minimal training needed |

| Cost | Higher upfront investment in RF scanner devices | Lower initial cost |

| Inventory Control | Real-time inventory updates | Delayed updates, risk of stock discrepancies |

| Productivity | Increased productivity with automation support | Dependent on manual effort and experience |

| Technology Dependence | High - relies on RF hardware and software | Low - manual tools only |

Overview of RF Scanner Operator Roles

RF Scanner Operators utilize handheld radio frequency devices to accurately track inventory movement and update warehouse management systems in real-time. Their role enhances order accuracy, increases picking speed, and reduces errors compared to Manual Pickers who rely on paper lists. This technology-driven approach streamlines warehousing processes and improves overall operational efficiency.

Overview of Manual Picker Roles

Manual pickers play a crucial role in warehousing by accurately selecting and retrieving items from storage locations using handheld lists or paper-based instructions. Their responsibilities include verifying product codes, ensuring order accuracy, and maintaining proper inventory levels. Unlike RF scanner operators, manual pickers rely heavily on visual inspection and manual record-keeping to fulfill orders efficiently.

Key Responsibilities of RF Scanner Operators

RF scanner operators play a crucial role in warehousing by efficiently managing inventory through real-time barcode scanning, ensuring accurate data capture and reducing errors. Their key responsibilities include scanning incoming and outgoing shipments, verifying product information, and updating inventory management systems instantly to maintain stock accuracy. Unlike manual pickers, RF scanner operators rely on technology to streamline order fulfillment processes and enhance operational productivity.

Key Responsibilities of Manual Pickers

Manual Pickers in warehousing are responsible for accurately selecting and gathering products based on order specifications without the use of RF scanners. They rely on paper pick lists or visual cues to identify items, ensuring correct quantities and proper handling to maintain inventory integrity. Manual Pickers also perform quality checks and prepare items for packaging and shipping, contributing to efficient order fulfillment and minimizing errors.

Required Skills and Qualifications

RF Scanner Operators require proficiency in using radio frequency technology, strong attention to detail, and the ability to navigate warehouse management systems efficiently. Manual Pickers must possess excellent physical stamina, basic inventory knowledge, and the ability to accurately follow picking lists without technological assistance. Both roles demand good communication skills and the capacity to work in fast-paced environments, but RF Scanner Operators benefit from technical training and familiarity with digital tools.

Efficiency and Accuracy Comparison

RF scanner operators significantly enhance warehouse efficiency by reducing picking time through real-time barcode scanning and automated data capture, minimizing human error. Manual pickers, relying on visual verification and handwritten documentation, often exhibit slower operation speeds and higher chances of mis-picks. Studies indicate that RF scanner use can improve accuracy rates up to 99.9%, compared to 95-97% accuracy typical in manual picking processes.

Technology Integration in Warehousing

RF scanner operators leverage advanced radio frequency technology to instantly capture and transmit data, significantly reducing errors and increasing inventory accuracy in warehousing operations. Manual pickers, in contrast, rely on traditional methods such as paper lists or verbal commands, which are more prone to human error and slower processing times. Integrating RF scanning technology enhances real-time inventory tracking, accelerates order fulfillment, and optimizes labor efficiency compared to manual picking processes.

Training and Onboarding Processes

RF scanner operators require focused training on handheld device navigation, barcode scanning accuracy, and real-time inventory updates, which typically reduces onboarding time by up to 30%. Manual pickers undergo extensive training on physical item handling, spatial awareness, and order accuracy, often resulting in longer onboarding durations. Investing in comprehensive technology-based training programs enhances efficiency and reduces errors in RF scanner operator onboarding compared to traditional manual picker training.

Health and Safety Considerations

RF scanner operators in warehousing benefit from ergonomic designs that reduce repetitive strain injuries and minimize physical exertion compared to manual pickers. Manual pickers face higher risks of musculoskeletal disorders due to heavy lifting, prolonged bending, and repetitive motions. Implementing RF scanners improves workplace safety by decreasing the likelihood of accidents and supporting compliance with occupational health standards.

Career Growth Opportunities

RF scanner operators benefit from advanced technological skills that increase their value for roles in warehouse automation and inventory management. Manual pickers often start with foundational tasks, which can limit rapid career advancement compared to operators proficient in radio frequency systems. Proficiency in RF technology opens pathways to supervisory positions and specialized logistics roles, enhancing long-term career growth in warehousing.

RF Scanner Operator vs Manual Picker Infographic

jobdiv.com

jobdiv.com