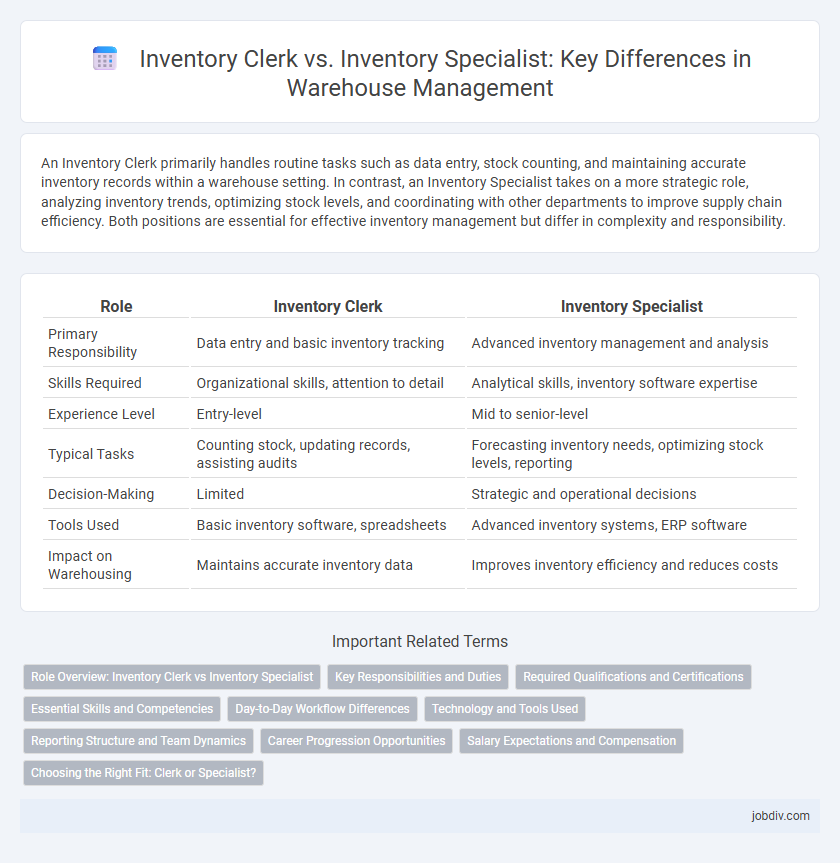

An Inventory Clerk primarily handles routine tasks such as data entry, stock counting, and maintaining accurate inventory records within a warehouse setting. In contrast, an Inventory Specialist takes on a more strategic role, analyzing inventory trends, optimizing stock levels, and coordinating with other departments to improve supply chain efficiency. Both positions are essential for effective inventory management but differ in complexity and responsibility.

Table of Comparison

| Role | Inventory Clerk | Inventory Specialist |

|---|---|---|

| Primary Responsibility | Data entry and basic inventory tracking | Advanced inventory management and analysis |

| Skills Required | Organizational skills, attention to detail | Analytical skills, inventory software expertise |

| Experience Level | Entry-level | Mid to senior-level |

| Typical Tasks | Counting stock, updating records, assisting audits | Forecasting inventory needs, optimizing stock levels, reporting |

| Decision-Making | Limited | Strategic and operational decisions |

| Tools Used | Basic inventory software, spreadsheets | Advanced inventory systems, ERP software |

| Impact on Warehousing | Maintains accurate inventory data | Improves inventory efficiency and reduces costs |

Role Overview: Inventory Clerk vs Inventory Specialist

Inventory Clerks primarily handle the day-to-day tracking and recording of stock levels, ensuring accurate data entry and physical inventory counts. Inventory Specialists focus on analyzing inventory metrics, optimizing stock control processes, and supporting supply chain strategies to improve overall efficiency. Both roles collaborate to maintain inventory accuracy but differ in scope, with Specialists taking a more analytical and strategic approach.

Key Responsibilities and Duties

Inventory Clerks maintain accurate records by tracking stock levels, processing shipments, and updating inventory databases to ensure seamless warehouse operations. Inventory Specialists oversee more complex tasks, including inventory audits, variance analysis, and coordinating inventory control procedures to optimize stock accuracy and reduce discrepancies. Both roles require proficiency in inventory management software and strong attention to detail to support efficient supply chain workflows.

Required Qualifications and Certifications

Inventory Clerks typically require a high school diploma or equivalent, basic computer skills, and familiarity with inventory management software, while Inventory Specialists often need an associate degree or higher and advanced proficiency in warehouse management systems (WMS). Certifications such as Certified Inventory Specialist (CIS) or Certified in Production and Inventory Management (CPIM) by APICS are more commonly expected for Inventory Specialists to validate their expertise in inventory control and supply chain processes. Both roles benefit from strong organizational skills, attention to detail, and experience with barcode scanning and data entry, but Specialists usually handle more complex inventory analysis and reporting tasks.

Essential Skills and Competencies

Inventory Clerks excel in data entry accuracy, basic stock management, and routine inventory audits, ensuring records are up-to-date and discrepancies are promptly reported. Inventory Specialists possess advanced analytical skills, proficiency with inventory management software, and expertise in optimizing stock levels to improve supply chain efficiency. Both roles require attention to detail and organizational abilities, but specialists typically handle complex forecasting and strategic inventory control.

Day-to-Day Workflow Differences

Inventory Clerks handle routine tasks such as receiving, counting, and recording stock levels to maintain accurate daily inventory records. Inventory Specialists perform advanced functions including analyzing inventory trends, coordinating audits, and optimizing stock replenishment processes to improve overall warehouse efficiency. The clerk's workflow centers on data entry and physical stock management, while the specialist emphasizes strategic inventory control and problem-solving.

Technology and Tools Used

Inventory Clerks primarily use traditional tools like barcode scanners, inventory management software, and spreadsheets to track stock levels, ensuring accurate data entry and transaction recording. Inventory Specialists leverage advanced technologies, including RFID systems, warehouse management systems (WMS), and data analytics platforms, to optimize inventory accuracy and streamline supply chain processes. Both roles require proficiency in inventory software, but specialists focus more on integrating automation and real-time data analysis for improved decision-making.

Reporting Structure and Team Dynamics

Inventory Clerks typically report to Warehouse Supervisors or Inventory Managers, handling day-to-day stock recording and data entry. Inventory Specialists often hold a more senior position, collaborating with cross-functional teams such as procurement, logistics, and finance to ensure accurate inventory levels and strategic stock management. The team dynamics emphasize Inventory Clerks supporting routine tasks while Inventory Specialists drive inventory accuracy and process improvements through detailed reporting and analysis.

Career Progression Opportunities

Inventory Clerks typically handle fundamental tasks such as data entry, stock counts, and order processing, serving as entry points in warehousing careers. Inventory Specialists advance by developing expertise in inventory analysis, optimization strategies, and advanced software tools, enabling them to manage complex stock control systems. Career progression from Inventory Clerk to Inventory Specialist often involves gaining certifications in inventory management and experience with ERP systems, opening pathways to supervisory or managerial roles within logistics and supply chain operations.

Salary Expectations and Compensation

Inventory Clerks typically earn between $30,000 and $45,000 annually, reflecting entry-level responsibilities in stock management and record-keeping. Inventory Specialists generally command higher salaries ranging from $45,000 to $65,000, driven by their advanced skills in data analysis, inventory optimization, and reporting. Compensation packages for Inventory Specialists often include performance bonuses and benefits that recognize their critical role in maintaining accurate inventory levels and supporting supply chain efficiency.

Choosing the Right Fit: Clerk or Specialist?

Choosing between an Inventory Clerk and an Inventory Specialist depends on the complexity and scale of your warehousing operations; Inventory Clerks typically handle routine tasks like data entry and stock counting, ensuring accurate records for daily inventory management. Inventory Specialists bring advanced skills in inventory analysis, forecasting, and implementing control systems, making them ideal for businesses requiring optimized stock flow and strategic oversight. Evaluating your warehouse's operational needs and long-term goals will help determine whether a Clerk's maintenance-focused role or a Specialist's analytical expertise is the right fit.

Inventory Clerk vs Inventory Specialist Infographic

jobdiv.com

jobdiv.com