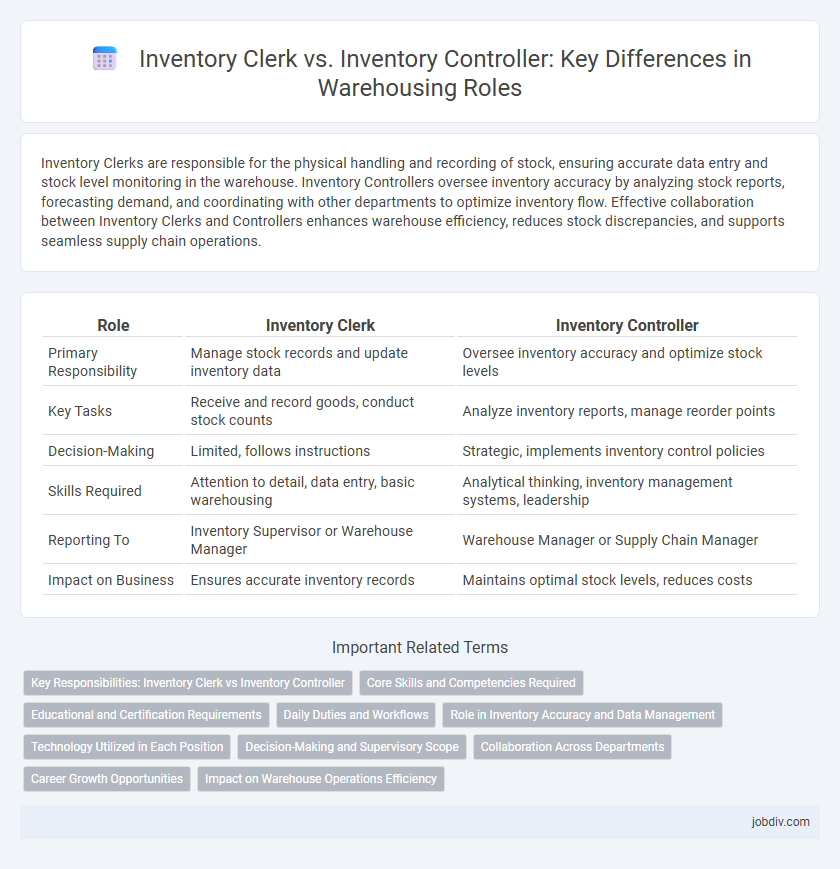

Inventory Clerks are responsible for the physical handling and recording of stock, ensuring accurate data entry and stock level monitoring in the warehouse. Inventory Controllers oversee inventory accuracy by analyzing stock reports, forecasting demand, and coordinating with other departments to optimize inventory flow. Effective collaboration between Inventory Clerks and Controllers enhances warehouse efficiency, reduces stock discrepancies, and supports seamless supply chain operations.

Table of Comparison

| Role | Inventory Clerk | Inventory Controller |

|---|---|---|

| Primary Responsibility | Manage stock records and update inventory data | Oversee inventory accuracy and optimize stock levels |

| Key Tasks | Receive and record goods, conduct stock counts | Analyze inventory reports, manage reorder points |

| Decision-Making | Limited, follows instructions | Strategic, implements inventory control policies |

| Skills Required | Attention to detail, data entry, basic warehousing | Analytical thinking, inventory management systems, leadership |

| Reporting To | Inventory Supervisor or Warehouse Manager | Warehouse Manager or Supply Chain Manager |

| Impact on Business | Ensures accurate inventory records | Maintains optimal stock levels, reduces costs |

Key Responsibilities: Inventory Clerk vs Inventory Controller

Inventory Clerks manage day-to-day inventory tasks such as receiving, inspecting, stocking, and updating inventory records to ensure accurate tracking of goods within the warehouse. Inventory Controllers oversee inventory accuracy through regular audits, analyze stock levels to prevent overstocking or shortages, and coordinate with procurement and logistics teams to optimize inventory flow. Both roles are crucial for maintaining efficient inventory management but differ in scope, with Clerks focusing on operational execution and Controllers on strategic oversight.

Core Skills and Competencies Required

Inventory Clerks require strong attention to detail, proficiency in inventory management software, and basic data entry skills to accurately record stock movements. Inventory Controllers need advanced analytical abilities, expertise in forecasting and demand planning, and leadership skills to optimize inventory levels and ensure efficient supply chain operations. Both roles demand excellent organizational skills and a solid understanding of warehouse processes, but Inventory Controllers focus more on strategic decision-making and process improvement.

Educational and Certification Requirements

Inventory Clerks typically require a high school diploma or equivalent, with on-the-job training being common for mastering inventory tracking and data entry systems. Inventory Controllers often hold a bachelor's degree in supply chain management, logistics, or business administration, combined with certifications such as Certified in Production and Inventory Management (CPIM) or Certified Supply Chain Professional (CSCP) to enhance strategic inventory optimization skills. Advanced knowledge of inventory software and regulatory compliance is essential for Inventory Controllers to effectively manage stock levels and forecasting accuracy.

Daily Duties and Workflows

Inventory Clerks handle daily tasks such as receiving, logging, and organizing stock to ensure accurate records and physical inventory alignment. Inventory Controllers focus on monitoring inventory levels, forecasting demand, and implementing efficient stock control measures to optimize warehouse operations. Both roles collaborate to maintain seamless inventory accuracy and support supply chain continuity.

Role in Inventory Accuracy and Data Management

An Inventory Clerk primarily focuses on maintaining accurate stock records through regular counting, updating databases, and reporting discrepancies, ensuring day-to-day inventory accuracy. In contrast, an Inventory Controller oversees broader inventory management strategies, analyzing data trends, coordinating audits, and implementing control measures to optimize stock levels and reduce errors. Both roles are crucial in warehousing but differ in scope, with clerks handling operational accuracy and controllers managing strategic data integrity.

Technology Utilized in Each Position

Inventory clerks often utilize barcode scanners, inventory management software, and handheld devices to track stock levels and update records efficiently. Inventory controllers typically employ advanced enterprise resource planning (ERP) systems, real-time analytics platforms, and automated replenishment tools to optimize inventory accuracy and streamline supply chain processes. Both roles rely on technology, but controllers leverage more sophisticated software for strategic planning and forecasting.

Decision-Making and Supervisory Scope

Inventory Clerks primarily handle data entry, stock tracking, and routine inventory audits, providing vital information but limited decision-making authority. Inventory Controllers oversee inventory accuracy, analyze stock levels, and make strategic decisions to optimize supply chain efficiency, often supervising inventory clerks and coordinating warehouse operations. The supervisory scope of an Inventory Controller includes managing team workflows and implementing inventory policies, whereas Inventory Clerks focus on executing assigned tasks.

Collaboration Across Departments

Inventory Clerks maintain accurate stock records and coordinate with warehouse staff for daily operations, while Inventory Controllers oversee stock levels and enforce inventory policies to optimize supply chain efficiency. Collaboration across departments involves Inventory Controllers working closely with procurement, sales, and finance teams to forecast demand and manage costs. Inventory Clerks support this process by providing real-time data updates and facilitating communication between warehouse personnel and other departments.

Career Growth Opportunities

Inventory Clerks often start with foundational tasks such as stocktaking and data entry, providing essential experience in inventory management. Inventory Controllers typically hold more advanced roles involving strategic planning, demand forecasting, and supply chain coordination, creating pathways to supervisory or operations management positions. Career growth opportunities favor Inventory Controllers due to their broader scope of responsibilities and impact on organizational efficiency.

Impact on Warehouse Operations Efficiency

Inventory Clerks directly manage stock accuracy by conducting regular counts and updating records, which minimizes errors and discrepancies in warehouse inventory. Inventory Controllers oversee inventory policies and forecasting, optimizing stock levels to reduce holding costs and prevent stockouts. Together, their roles enhance warehouse operations efficiency by ensuring precise inventory data and strategic inventory management.

Inventory Clerk vs Inventory Controller Infographic

jobdiv.com

jobdiv.com