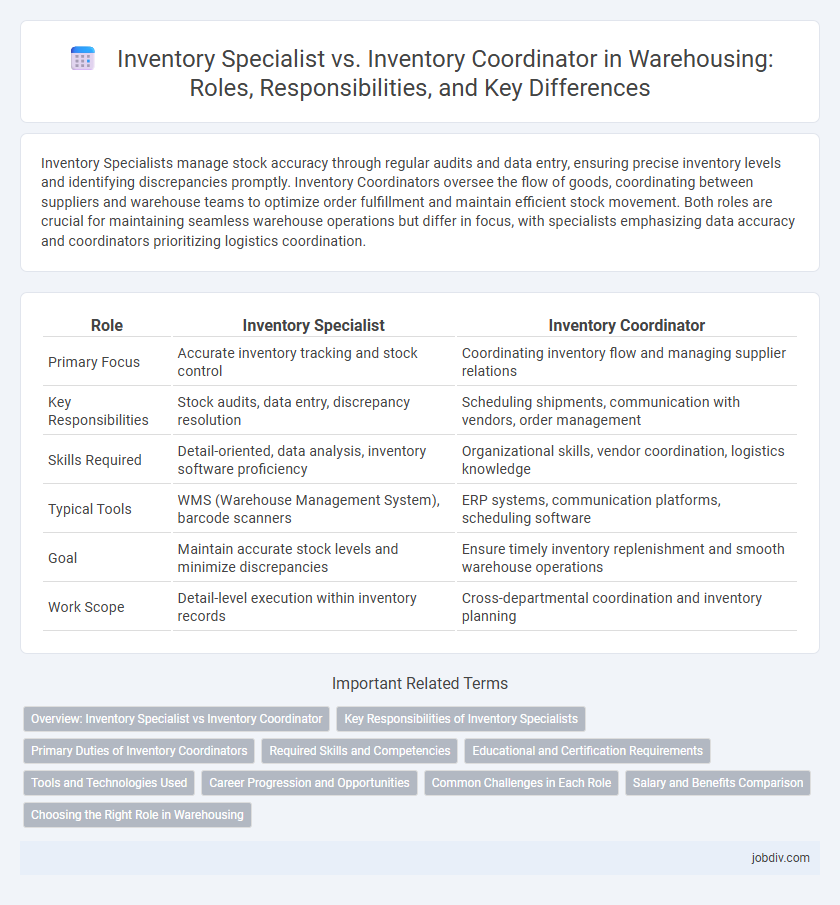

Inventory Specialists manage stock accuracy through regular audits and data entry, ensuring precise inventory levels and identifying discrepancies promptly. Inventory Coordinators oversee the flow of goods, coordinating between suppliers and warehouse teams to optimize order fulfillment and maintain efficient stock movement. Both roles are crucial for maintaining seamless warehouse operations but differ in focus, with specialists emphasizing data accuracy and coordinators prioritizing logistics coordination.

Table of Comparison

| Role | Inventory Specialist | Inventory Coordinator |

|---|---|---|

| Primary Focus | Accurate inventory tracking and stock control | Coordinating inventory flow and managing supplier relations |

| Key Responsibilities | Stock audits, data entry, discrepancy resolution | Scheduling shipments, communication with vendors, order management |

| Skills Required | Detail-oriented, data analysis, inventory software proficiency | Organizational skills, vendor coordination, logistics knowledge |

| Typical Tools | WMS (Warehouse Management System), barcode scanners | ERP systems, communication platforms, scheduling software |

| Goal | Maintain accurate stock levels and minimize discrepancies | Ensure timely inventory replenishment and smooth warehouse operations |

| Work Scope | Detail-level execution within inventory records | Cross-departmental coordination and inventory planning |

Overview: Inventory Specialist vs Inventory Coordinator

An Inventory Specialist manages stock levels by tracking inventory accuracy, conducting audits, and resolving discrepancies to maintain optimal warehouse operations. An Inventory Coordinator oversees the flow of goods, coordinates order fulfillment, and communicates with suppliers and warehouse teams to ensure timely inventory replenishment. Both roles are crucial for efficient inventory management but emphasize distinct responsibilities in accuracy control versus operational coordination.

Key Responsibilities of Inventory Specialists

Inventory Specialists are responsible for accurately tracking stock levels, conducting regular audits, and maintaining detailed records to ensure inventory accuracy. They analyze discrepancies between physical counts and recorded inventory, implement corrective measures, and coordinate with warehouse staff to optimize storage and retrieval processes. Their expertise in inventory management software and strong attention to detail helps prevent stockouts and overstock situations, supporting efficient warehouse operations.

Primary Duties of Inventory Coordinators

Inventory Coordinators primarily manage day-to-day inventory activities, ensuring accurate record-keeping and timely updates in warehouse management systems. They coordinate stock replenishment, monitor inventory levels, and facilitate communication between procurement and warehouse teams to prevent stockouts or overstock situations. Their role emphasizes maintaining inventory accuracy and supporting operational efficiency through detailed tracking and reporting.

Required Skills and Competencies

Inventory Specialists require strong analytical skills, proficiency in inventory management software, and attention to detail for accurate stock tracking and data entry. Inventory Coordinators need excellent communication abilities, organizational skills, and experience in coordinating inventory flow between departments to ensure seamless warehousing operations. Both roles demand problem-solving capabilities and knowledge of supply chain processes to optimize stock control and distribution.

Educational and Certification Requirements

Inventory Specialists typically require a high school diploma or equivalent, with many employers preferring candidates who have completed courses in logistics, supply chain management, or inventory control. Inventory Coordinators often need a higher level of education, such as an associate or bachelor's degree in business administration, supply chain management, or a related field, along with certifications like APICS CPIM or Six Sigma. Both roles benefit from certifications in inventory management software and processes, but Inventory Coordinators usually hold advanced credentials to support their broader responsibilities in coordinating inventory activities.

Tools and Technologies Used

Inventory Specialists utilize advanced barcode scanners, inventory management software like Fishbowl or Oracle NetSuite, and RFID technology to accurately track and manage stock levels. Inventory Coordinators often rely on warehouse management systems (WMS) such as SAP EWM or Manhattan Associates, alongside Excel and data analytics tools, to coordinate inventory flow and optimize order fulfillment. Both roles leverage cloud-based platforms and mobile devices to enhance real-time inventory visibility and streamline warehousing operations.

Career Progression and Opportunities

Inventory Specialists manage stock accuracy and perform regular audits, ensuring optimal inventory levels and reducing discrepancies. Inventory Coordinators oversee broader supply chain processes, including vendor communication and logistics coordination, positioning themselves for higher management roles. Career progression often leads from Specialist roles to Coordinator positions, offering expanded responsibilities and opportunities in supply chain management.

Common Challenges in Each Role

Inventory Specialists often face challenges in accurate stock tracking and timely reconciliation, which can lead to discrepancies affecting order fulfillment and supply chain efficiency. Inventory Coordinators frequently manage complex communication between departments and vendors, encountering difficulties in synchronizing inventory data and resolving supply delays. Both roles demand meticulous attention to detail and advanced inventory management systems to minimize errors and maintain operational flow in warehousing environments.

Salary and Benefits Comparison

Inventory Specialists typically earn between $40,000 and $60,000 annually, with benefits including health insurance, paid time off, and retirement plans. Inventory Coordinators often command slightly higher salaries ranging from $50,000 to $70,000, reflecting increased responsibilities such as supervising inventory processes and coordinating teams. Both roles may offer bonuses, professional development opportunities, and varying levels of job security depending on the company and industry.

Choosing the Right Role in Warehousing

An Inventory Specialist focuses on managing stock levels, conducting audits, and ensuring accurate record-keeping to optimize inventory control. Inventory Coordinators oversee the coordination of inventory flow, liaising between suppliers, warehouse staff, and logistics to streamline operations. Choosing the right warehousing role depends on whether you prefer hands-on inventory management or organizational coordination within the supply chain.

Inventory Specialist vs Inventory Coordinator Infographic

jobdiv.com

jobdiv.com