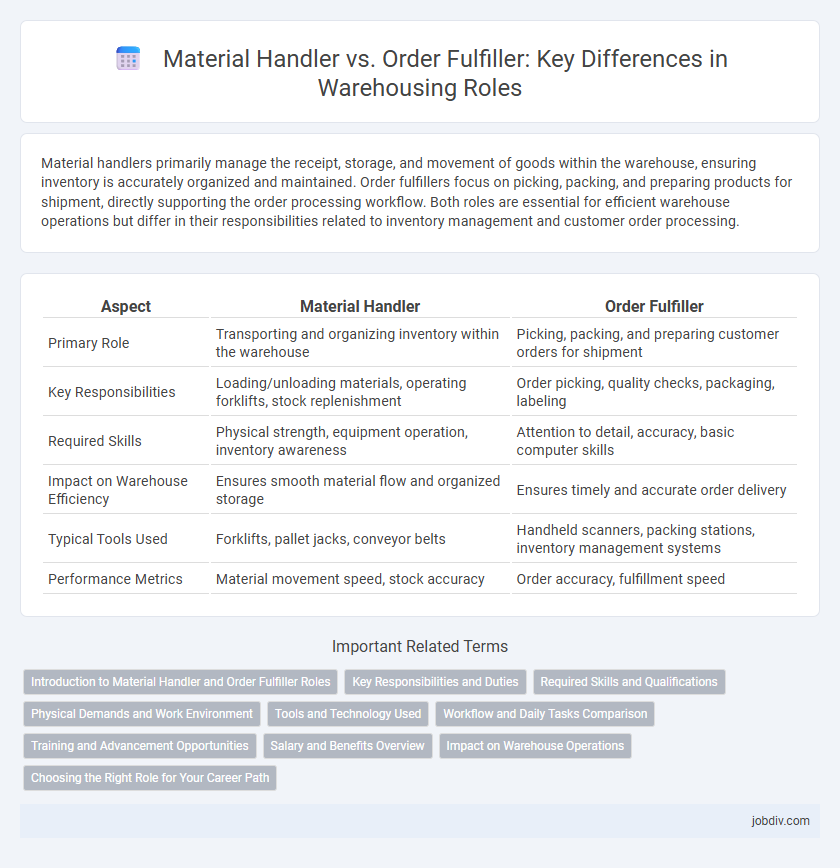

Material handlers primarily manage the receipt, storage, and movement of goods within the warehouse, ensuring inventory is accurately organized and maintained. Order fulfillers focus on picking, packing, and preparing products for shipment, directly supporting the order processing workflow. Both roles are essential for efficient warehouse operations but differ in their responsibilities related to inventory management and customer order processing.

Table of Comparison

| Aspect | Material Handler | Order Fulfiller |

|---|---|---|

| Primary Role | Transporting and organizing inventory within the warehouse | Picking, packing, and preparing customer orders for shipment |

| Key Responsibilities | Loading/unloading materials, operating forklifts, stock replenishment | Order picking, quality checks, packaging, labeling |

| Required Skills | Physical strength, equipment operation, inventory awareness | Attention to detail, accuracy, basic computer skills |

| Impact on Warehouse Efficiency | Ensures smooth material flow and organized storage | Ensures timely and accurate order delivery |

| Typical Tools Used | Forklifts, pallet jacks, conveyor belts | Handheld scanners, packing stations, inventory management systems |

| Performance Metrics | Material movement speed, stock accuracy | Order accuracy, fulfillment speed |

Introduction to Material Handler and Order Fulfiller Roles

Material handlers are responsible for moving, storing, and managing inventory within warehouses, ensuring materials are accurately received, stored, and prepared for production or shipping. Order fulfillers specialize in picking, packing, and shipping customer orders, focusing on accuracy and efficiency to meet delivery deadlines. Both roles are essential to warehouse operations, optimizing inventory flow and customer satisfaction.

Key Responsibilities and Duties

Material handlers manage inventory by receiving, storing, and distributing materials within the warehouse, ensuring accurate stock control and efficient flow of goods. Order fulfillers pick, pack, and prepare customer orders according to specifications, maintaining order accuracy and timely shipment dispatch. Both roles are essential for seamless warehouse operations but focus respectively on inventory management versus order processing.

Required Skills and Qualifications

Material Handlers require physical strength, familiarity with inventory management software, and the ability to operate forklifts and pallet jacks safely. Order Fulfillers need strong attention to detail, proficiency in order processing systems, and excellent organizational skills to ensure accurate picking and packing. Both roles benefit from effective communication abilities and a basic understanding of warehouse safety protocols.

Physical Demands and Work Environment

Material Handlers often engage in heavy lifting, operating forklifts, and moving large pallets in warehouse settings with fluctuating temperatures and noise levels. Order Fulfillers primarily perform repetitive tasks such as picking and packing items, requiring sustained manual dexterity and attention to detail in well-lit, climate-controlled environments. Both roles demand physical stamina and adherence to safety protocols but differ in the intensity and specific nature of physical exertion within the warehouse ecosystem.

Tools and Technology Used

Material handlers utilize advanced equipment such as forklifts, pallet jacks, and conveyor systems to efficiently move and store inventory within warehouses. Order fulfillers leverage barcode scanners, warehouse management systems (WMS), and picking robots to accurately process and package customer orders. Integration of RFID technology and automated sorting enhances productivity for both roles, streamlining inventory tracking and order accuracy.

Workflow and Daily Tasks Comparison

Material Handlers primarily focus on receiving, storing, and moving inventory within the warehouse, ensuring accurate stock placement and maintaining inventory accuracy through regular cycle counts. Order Fulfillers concentrate on picking, packing, and preparing customer orders for shipment, emphasizing speed and accuracy to meet delivery deadlines. Workflow efficiency in warehouses improves when Material Handlers optimize inventory organization, enabling Order Fulfillers to access items quickly and reduce order processing time.

Training and Advancement Opportunities

Material handlers receive specialized training in forklift operation, inventory management, and safety protocols, positioning them for advancement into supervisory roles or equipment operation specialists. Order fulfillers focus on order accuracy, picking techniques, and packing efficiency, with training geared toward quality control and warehouse logistics, often advancing into inventory control or team lead positions. Cross-training in both functions enhances career growth by increasing versatility and operational understanding within warehousing environments.

Salary and Benefits Overview

Material handlers typically earn an average salary ranging from $30,000 to $45,000 annually, with benefits including health insurance, retirement plans, and paid time off; order fulfillers often have a similar pay scale but may receive performance-based bonuses and flexible scheduling options. Benefits packages for both roles generally cover medical, dental, and vision insurance, with some employers offering tuition assistance and career development programs. Salary variations depend on location, experience, and company size, with material handlers sometimes commanding higher wages in industries requiring specialized equipment operation.

Impact on Warehouse Operations

Material handlers play a critical role in warehouse operations by efficiently managing the receipt, storage, and movement of inventory to maintain optimal stock levels and streamline workflow. Order fulfillers specialize in picking, packing, and shipping customer orders, directly impacting order accuracy and delivery speed. Together, both roles enhance overall warehouse productivity, reduce turnaround times, and improve inventory accuracy metrics essential for supply chain efficiency.

Choosing the Right Role for Your Career Path

Material Handlers specialize in moving, storing, and organizing inventory within warehouses, requiring skills in equipment operation and inventory management, ideal for candidates seeking physical roles in logistics. Order Fulfillers focus on picking, packing, and preparing customer orders for shipment, emphasizing accuracy and speed, suitable for those who prefer detail-oriented tasks and direct order processing. Selecting the right role depends on your strengths and career goals, with Material Handler roles offering pathway to warehouse supervision and Order Fulfiller positions leading to supply chain coordination.

Material Handler vs Order Fulfiller Infographic

jobdiv.com

jobdiv.com