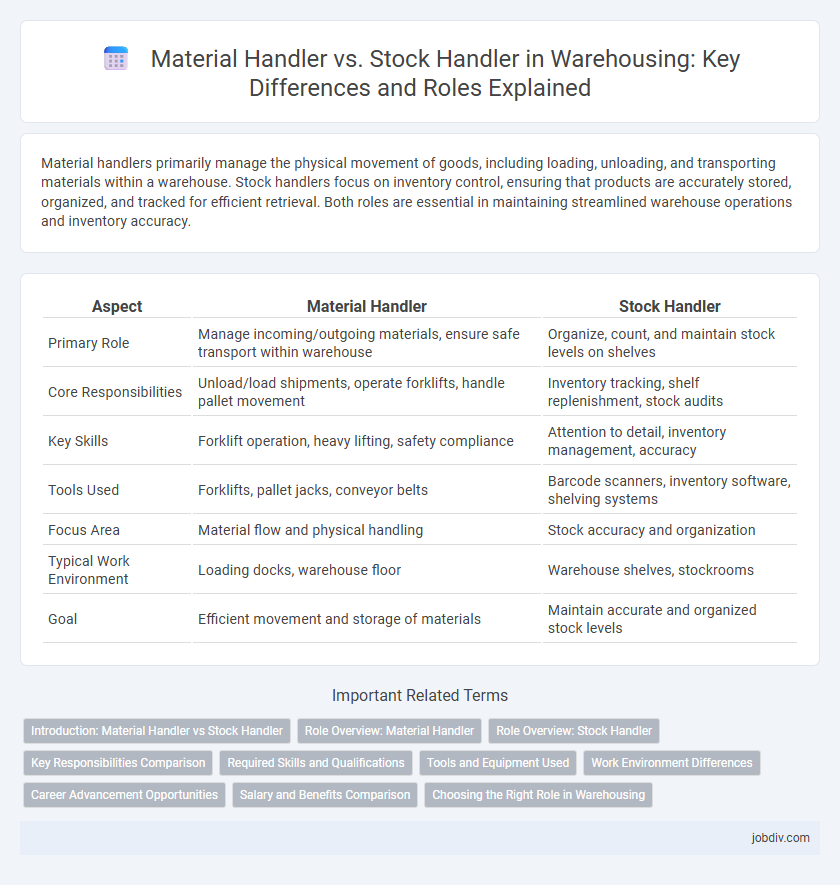

Material handlers primarily manage the physical movement of goods, including loading, unloading, and transporting materials within a warehouse. Stock handlers focus on inventory control, ensuring that products are accurately stored, organized, and tracked for efficient retrieval. Both roles are essential in maintaining streamlined warehouse operations and inventory accuracy.

Table of Comparison

| Aspect | Material Handler | Stock Handler |

|---|---|---|

| Primary Role | Manage incoming/outgoing materials, ensure safe transport within warehouse | Organize, count, and maintain stock levels on shelves |

| Core Responsibilities | Unload/load shipments, operate forklifts, handle pallet movement | Inventory tracking, shelf replenishment, stock audits |

| Key Skills | Forklift operation, heavy lifting, safety compliance | Attention to detail, inventory management, accuracy |

| Tools Used | Forklifts, pallet jacks, conveyor belts | Barcode scanners, inventory software, shelving systems |

| Focus Area | Material flow and physical handling | Stock accuracy and organization |

| Typical Work Environment | Loading docks, warehouse floor | Warehouse shelves, stockrooms |

| Goal | Efficient movement and storage of materials | Maintain accurate and organized stock levels |

Introduction: Material Handler vs Stock Handler

Material handlers play a critical role in warehousing by efficiently moving, loading, and unloading materials within the facility, ensuring smooth inventory flow and operational productivity. Stock handlers specialize in organizing, counting, and managing inventory levels, maintaining accurate stock records to support supply chain accuracy. Both roles contribute to warehouse efficiency but focus on different aspects of material and inventory management.

Role Overview: Material Handler

Material Handlers are responsible for receiving, moving, and storing materials within a warehouse, ensuring accurate inventory management and efficient workflow. They operate forklifts, pallet jacks, and other equipment to load and unload shipments, maintain organized storage areas, and prepare materials for production or distribution. Material Handlers play a critical role in maintaining supply chain continuity by managing inventory accuracy and supporting order fulfillment processes.

Role Overview: Stock Handler

Stock Handlers play a crucial role in warehouse operations by managing inventory accuracy and organization. Their responsibilities include receiving, storing, and distributing materials, ensuring stock levels are maintained, and conducting regular cycle counts to prevent discrepancies. Efficient stock handling minimizes delays in order fulfillment and supports seamless supply chain management.

Key Responsibilities Comparison

Material Handlers are primarily responsible for receiving, moving, and organizing raw materials and products within the warehouse, ensuring accurate inventory tracking and safe handling of goods. Stock Handlers focus on maintaining inventory levels, conducting regular stock counts, and replenishing shelves or storage locations to meet operational demands. Both roles require coordination with warehouse management systems and adherence to safety protocols, but Material Handlers emphasize logistics and transportation, while Stock Handlers concentrate on inventory accuracy and availability.

Required Skills and Qualifications

Material Handlers require skills in operating forklifts, inventory management systems, and physical stamina for lifting heavy items. Stock Handlers need attention to detail for accurate stock counting, basic computer literacy for updating inventory records, and organizational skills to maintain orderly storage. Both roles typically require high school diplomas and safety training certifications relevant to warehouse operations.

Tools and Equipment Used

Material handlers primarily use forklifts, pallet jacks, conveyor systems, and automated storage and retrieval systems (AS/RS) to move and organize heavy goods efficiently. Stock handlers typically rely on hand-held scanners, inventory management software, shelving units, and carts to manage and maintain stock accuracy on warehouse floors. Both roles require safety equipment such as gloves, hard hats, and steel-toe boots to ensure safe handling of materials.

Work Environment Differences

Material handlers typically operate in dynamic, high-traffic warehouse environments that require frequent movement of heavy goods using forklifts or pallet jacks. Stock handlers often work in more controlled settings such as retail warehouses or stockrooms, where the focus is on inventory organization, shelving, and preparing stock for shipment. Safety protocols and physical demands vary, with material handlers facing greater exposure to heavy lifting and machinery operation.

Career Advancement Opportunities

Material handlers often access broader career advancement opportunities by gaining experience in inventory management, logistics coordination, and equipment operation, enabling progression to supervisory or logistics specialist roles. Stock handlers typically focus on inventory monitoring and stock replenishment, which can lead to positions such as inventory control analyst or warehouse clerk. Both roles provide foundational skills, but material handler positions generally offer a more diverse skill set conducive to upward mobility within supply chain management.

Salary and Benefits Comparison

Material handlers typically earn a higher average salary, ranging from $30,000 to $45,000 annually, compared to stock handlers who usually make between $25,000 and $40,000. Material handlers often receive more comprehensive benefits packages, including health insurance, paid time off, and retirement plans, while stock handlers may have limited or less robust benefits. Employers tend to offer bonuses and overtime pay more frequently to material handlers due to the physical demands and specialized skills required in their roles.

Choosing the Right Role in Warehousing

Choosing the right role in warehousing depends on the specific operational needs and skill sets required; material handlers specialize in moving, packaging, and managing raw materials, often using machinery like forklifts, while stock handlers focus on organizing, counting, and maintaining inventory accuracy on warehouse shelves. Effective warehousing operations rely on clear role distinctions to optimize workflow efficiency, minimize errors, and ensure timely order fulfillment. Evaluating job descriptions, physical demands, and technical requirements helps businesses assign roles that align with both worker capabilities and warehouse productivity goals.

Material Handler vs Stock Handler Infographic

jobdiv.com

jobdiv.com