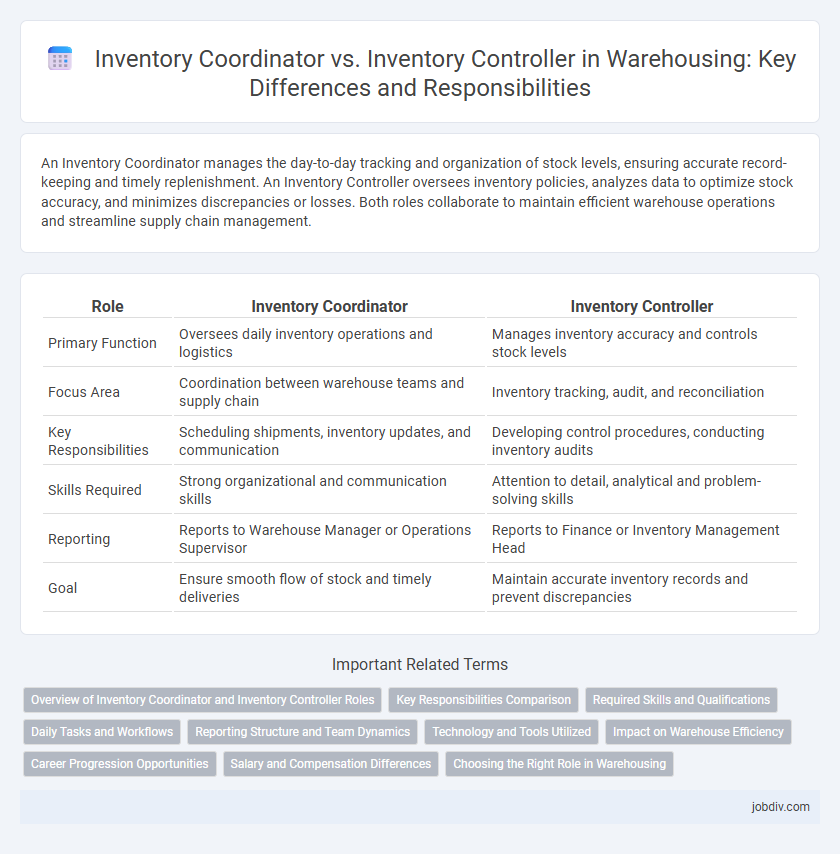

An Inventory Coordinator manages the day-to-day tracking and organization of stock levels, ensuring accurate record-keeping and timely replenishment. An Inventory Controller oversees inventory policies, analyzes data to optimize stock accuracy, and minimizes discrepancies or losses. Both roles collaborate to maintain efficient warehouse operations and streamline supply chain management.

Table of Comparison

| Role | Inventory Coordinator | Inventory Controller |

|---|---|---|

| Primary Function | Oversees daily inventory operations and logistics | Manages inventory accuracy and controls stock levels |

| Focus Area | Coordination between warehouse teams and supply chain | Inventory tracking, audit, and reconciliation |

| Key Responsibilities | Scheduling shipments, inventory updates, and communication | Developing control procedures, conducting inventory audits |

| Skills Required | Strong organizational and communication skills | Attention to detail, analytical and problem-solving skills |

| Reporting | Reports to Warehouse Manager or Operations Supervisor | Reports to Finance or Inventory Management Head |

| Goal | Ensure smooth flow of stock and timely deliveries | Maintain accurate inventory records and prevent discrepancies |

Overview of Inventory Coordinator and Inventory Controller Roles

Inventory Coordinators manage day-to-day stock flow, ensuring accurate inventory levels through order processing, receiving, and record maintenance. Inventory Controllers focus on strategic oversight, analyzing inventory data to optimize stock levels, minimize shrinkage, and improve supply chain efficiency. Both roles are essential for effective warehouse management, balancing operational accuracy with strategic inventory planning.

Key Responsibilities Comparison

An Inventory Coordinator manages stock levels by tracking incoming and outgoing shipments and coordinating with suppliers to ensure timely replenishment. An Inventory Controller focuses on maintaining accurate inventory records through audits, discrepancy resolution, and implementing inventory control systems. Both roles are crucial for optimizing warehouse efficiency, with the Coordinator emphasizing logistical flow and the Controller ensuring data accuracy and compliance.

Required Skills and Qualifications

Inventory Coordinators require strong organizational skills, proficiency in inventory management software, and the ability to communicate effectively with warehouse teams to ensure accurate stock levels. Inventory Controllers demand advanced analytical skills, experience in demand forecasting, and expertise in regulatory compliance and audit procedures to maintain optimal inventory accuracy. Both roles typically require a background in logistics or supply chain management, attention to detail, and proficiency in data analysis tools.

Daily Tasks and Workflows

An Inventory Coordinator manages daily stock levels by receiving shipments, updating inventory records, and coordinating with suppliers to ensure timely replenishment. An Inventory Controller focuses on auditing stock accuracy, analyzing inventory discrepancies, and implementing control procedures to optimize inventory turnover and reduce losses. Both roles require proficiency in warehouse management systems (WMS) and collaboration with logistics teams to maintain efficient workflows.

Reporting Structure and Team Dynamics

An Inventory Coordinator typically reports to the Inventory Manager or Warehouse Supervisor, focusing on day-to-day inventory tracking and data entry, collaborating closely with warehouse staff to ensure accurate stock levels. In contrast, an Inventory Controller often holds a more strategic role, reporting to senior management or operations directors, overseeing inventory policies, and leading cross-functional teams to optimize inventory accuracy and reduce discrepancies. Team dynamics for Coordinators emphasize operational support and communication with logistics, while Controllers drive performance metrics and compliance across departments.

Technology and Tools Utilized

Inventory Coordinators primarily use warehouse management systems (WMS) and barcode scanning technology to track stock levels and update inventory records in real time. Inventory Controllers leverage advanced analytics software, integrated ERP systems, and automated replenishment tools to optimize inventory turnover and reduce stock discrepancies. Both roles depend on RFID technology and cloud-based platforms for enhanced visibility and accuracy in inventory management.

Impact on Warehouse Efficiency

Inventory Coordinators streamline warehouse operations by managing real-time stock levels and coordinating order fulfillment, directly reducing delays and minimizing errors. Inventory Controllers focus on auditing inventory accuracy and implementing control measures, which ensures data integrity and prevents stock discrepancies. Together, their roles enhance warehouse efficiency by maintaining optimal inventory flow and accuracy, reducing holding costs, and improving order processing speed.

Career Progression Opportunities

Inventory Coordinators often begin their careers handling day-to-day stock management and data entry, gaining essential skills in inventory tracking and communication. Progression to Inventory Controller roles involves increased responsibility for overseeing inventory accuracy, implementing control systems, and supervising teams, which requires strong analytical and leadership abilities. Career advancement from Coordinator to Controller can lead to senior management positions such as Inventory Manager or Supply Chain Analyst, emphasizing strategic planning and inventory optimization within warehousing operations.

Salary and Compensation Differences

Inventory Coordinators typically earn a salary ranging from $40,000 to $55,000 annually, reflecting their focus on tracking stock levels and coordinating shipments. Inventory Controllers command higher compensation, often between $55,000 and $75,000 per year, due to their responsibility for overseeing inventory accuracy, auditing, and strategic stock management. Salary differences stem from the increased scope of duties and decision-making authority held by Inventory Controllers in warehousing operations.

Choosing the Right Role in Warehousing

Choosing the right role in warehousing depends on the specific needs of inventory management and operational goals. An Inventory Coordinator typically focuses on managing stock levels, coordinating shipments, and facilitating communication between suppliers and warehouse staff, ensuring smooth daily operations. In contrast, an Inventory Controller emphasizes accuracy in inventory data, conducts audits, and implements control measures to minimize discrepancies and optimize inventory turnover rates.

Inventory Coordinator vs Inventory Controller Infographic

jobdiv.com

jobdiv.com