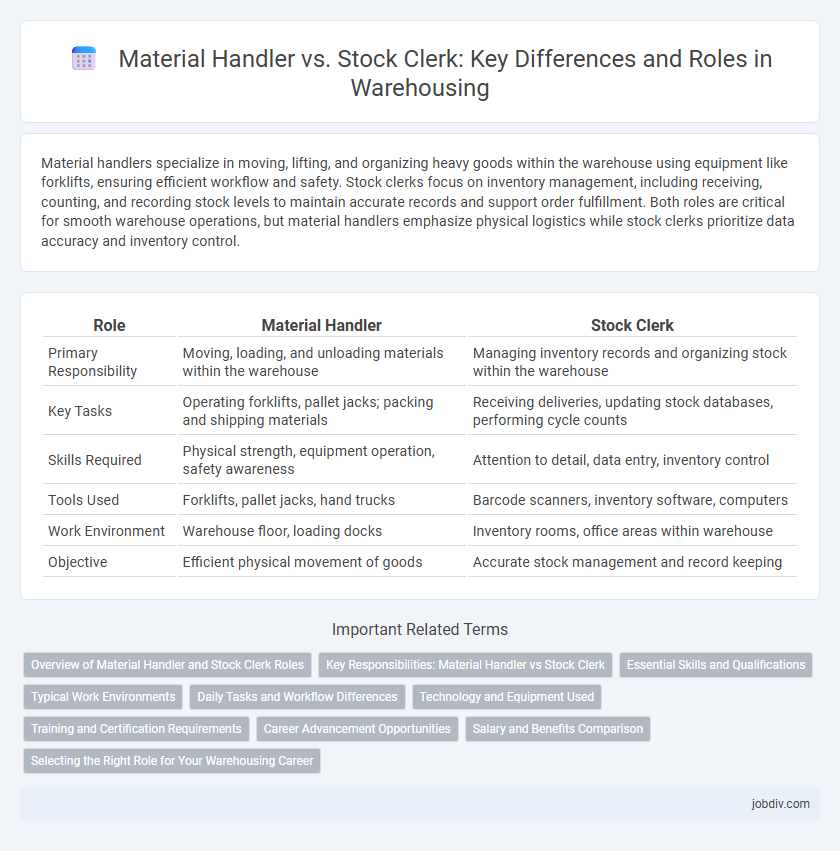

Material handlers specialize in moving, lifting, and organizing heavy goods within the warehouse using equipment like forklifts, ensuring efficient workflow and safety. Stock clerks focus on inventory management, including receiving, counting, and recording stock levels to maintain accurate records and support order fulfillment. Both roles are critical for smooth warehouse operations, but material handlers emphasize physical logistics while stock clerks prioritize data accuracy and inventory control.

Table of Comparison

| Role | Material Handler | Stock Clerk |

|---|---|---|

| Primary Responsibility | Moving, loading, and unloading materials within the warehouse | Managing inventory records and organizing stock within the warehouse |

| Key Tasks | Operating forklifts, pallet jacks; packing and shipping materials | Receiving deliveries, updating stock databases, performing cycle counts |

| Skills Required | Physical strength, equipment operation, safety awareness | Attention to detail, data entry, inventory control |

| Tools Used | Forklifts, pallet jacks, hand trucks | Barcode scanners, inventory software, computers |

| Work Environment | Warehouse floor, loading docks | Inventory rooms, office areas within warehouse |

| Objective | Efficient physical movement of goods | Accurate stock management and record keeping |

Overview of Material Handler and Stock Clerk Roles

Material Handler roles encompass the physical movement, loading, unloading, and organization of inventory within warehouses, ensuring efficient material flow and accuracy in stock placement. Stock Clerks primarily focus on inventory management tasks such as receiving shipments, recording stock levels, and maintaining accurate inventory records using warehouse management systems. Both positions contribute to operational efficiency but differ in their emphasis on physical handling versus administrative inventory control.

Key Responsibilities: Material Handler vs Stock Clerk

Material Handlers focus on the physical movement, loading, unloading, and transportation of goods within the warehouse, employing equipment such as forklifts and pallet jacks to ensure efficient material flow. Stock Clerks manage inventory by receiving, organizing, counting, and recording stock levels, maintaining accurate documentation to support inventory control and timely order fulfillment. Both roles are critical in warehouse operations, with Material Handlers emphasizing logistics and Stock Clerks concentrating on inventory accuracy and data management.

Essential Skills and Qualifications

Material Handlers require physical strength, forklift certification, and proficiency in inventory management systems to efficiently move and organize stock within warehouses. Stock Clerks must possess strong organizational skills, attention to detail, and expertise in data entry software to accurately track inventory levels and process orders. Both roles benefit from effective communication abilities and a solid understanding of warehouse safety protocols to maintain operational efficiency.

Typical Work Environments

Material Handlers typically work in dynamic industrial settings such as manufacturing plants, distribution centers, and large warehouses where heavy machinery and equipment are used for moving goods. Stock Clerks are more commonly found in retail stores, smaller warehouses, and storerooms, where their tasks involve inventory control and organization in less physically demanding environments. Both roles require efficiency in managing inventory, but Material Handlers operate in more physically intensive and machinery-driven environments compared to the more administrative and organized space of Stock Clerks.

Daily Tasks and Workflow Differences

Material Handlers primarily focus on loading, unloading, and moving inventory within the warehouse using equipment such as forklifts and pallet jacks, ensuring efficient material flow. Stock Clerks handle inventory tracking, organizing shelves, and updating stock records using warehouse management systems to maintain accurate inventory data. Both roles support warehouse operations but differ in physical labor intensity and administrative responsibilities influencing daily workflows.

Technology and Equipment Used

Material handlers utilize advanced automation equipment such as conveyor systems, forklifts with RFID integration, and barcode scanners to efficiently move and track inventory in warehouses. Stock clerks rely more heavily on warehouse management software (WMS) and handheld devices to update stock levels, perform cycle counts, and manage order fulfillment accurately. Both roles leverage technology to optimize inventory accuracy, reduce errors, and increase overall warehouse efficiency.

Training and Certification Requirements

Material handlers typically require training in equipment operation such as forklifts and safety protocols, often obtaining OSHA forklift certification to comply with regulatory standards. Stock clerks need proficiency in inventory management software and basic safety training, with certifications in warehouse logistics or inventory control enhancing job performance. Both roles benefit from continual professional development to meet evolving industry regulations and efficiency standards.

Career Advancement Opportunities

Material Handlers often have greater career advancement opportunities due to their hands-on experience with inventory management, equipment operation, and logistics coordination, which can lead to supervisory or warehouse management roles. Stock Clerks typically perform more clerical tasks such as inventory recording and shelf stocking, offering fewer pathways to higher positions but valuable experience for roles in inventory control or retail management. Both positions provide foundational skills in warehousing, but Material Handlers generally access broader leadership and specialized job prospects.

Salary and Benefits Comparison

Material handlers typically earn a median annual salary of $32,000 to $40,000, while stock clerks average between $27,000 and $35,000, reflecting differences in job responsibilities and skill requirements. Material handlers often receive benefits such as healthcare, retirement plans, and paid leave, with some positions offering overtime pay due to physical labor demands. Stock clerks may have access to similar benefits but usually experience fewer opportunities for overtime and may receive lower overall compensation in warehousing environments.

Selecting the Right Role for Your Warehousing Career

Material handlers excel in physically moving and organizing products within warehouses, utilizing equipment like forklifts and pallet jacks to manage inventory efficiently. Stock clerks specialize in tracking inventory records, performing cycle counts, and ensuring accurate stock levels through database management and barcode scanning technology. Choosing between these roles depends on your strengths in physical labor versus administrative accuracy, aligning your warehousing career with hands-on operational tasks or detailed inventory control responsibilities.

Material Handler vs Stock Clerk Infographic

jobdiv.com

jobdiv.com