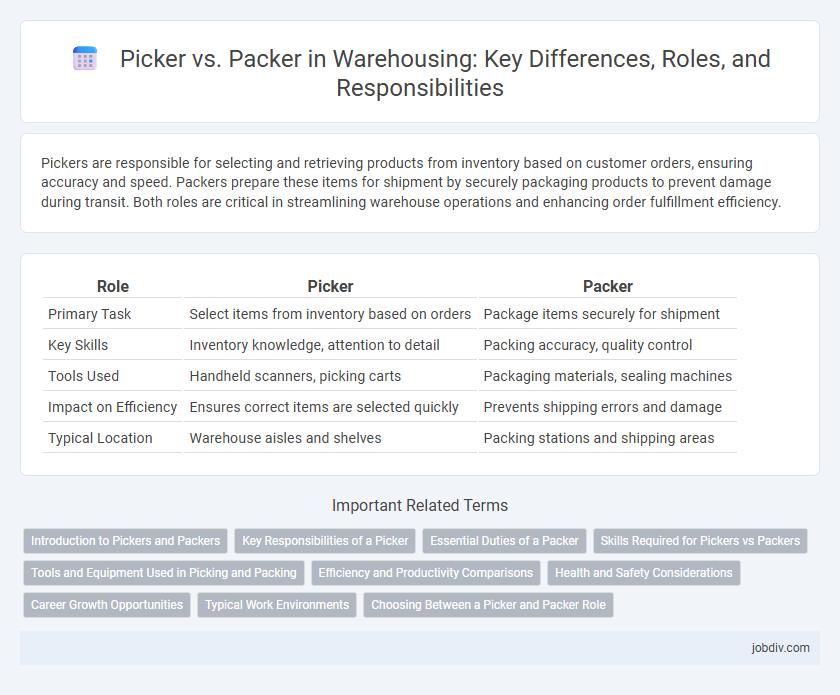

Pickers are responsible for selecting and retrieving products from inventory based on customer orders, ensuring accuracy and speed. Packers prepare these items for shipment by securely packaging products to prevent damage during transit. Both roles are critical in streamlining warehouse operations and enhancing order fulfillment efficiency.

Table of Comparison

| Role | Picker | Packer |

|---|---|---|

| Primary Task | Select items from inventory based on orders | Package items securely for shipment |

| Key Skills | Inventory knowledge, attention to detail | Packing accuracy, quality control |

| Tools Used | Handheld scanners, picking carts | Packaging materials, sealing machines |

| Impact on Efficiency | Ensures correct items are selected quickly | Prevents shipping errors and damage |

| Typical Location | Warehouse aisles and shelves | Packing stations and shipping areas |

Introduction to Pickers and Packers

Pickers specialize in selecting specific products from inventory based on customer orders, ensuring accuracy and efficiency in the order fulfillment process. Packers focus on securely packaging these items to prevent damage during shipping, optimizing space and materials used. Together, pickers and packers streamline warehouse operations, enhancing overall productivity and customer satisfaction.

Key Responsibilities of a Picker

The key responsibilities of a picker in warehousing include accurately selecting and retrieving items from inventory based on order specifications, ensuring the correct quantity and quality of products before packing. Pickers must efficiently navigate warehouse locations using handheld devices or picking lists to minimize errors and maintain inventory accuracy. Timely and precise order fulfillment by pickers directly impacts overall warehouse productivity and customer satisfaction.

Essential Duties of a Packer

A packer plays a crucial role in warehousing by preparing products for shipment, ensuring items are securely wrapped, labeled, and organized according to order specifications. Their essential duties include inspecting products for quality, assembling appropriate packaging materials, and maintaining accurate documentation to facilitate smooth inventory tracking. Efficient packing minimizes damage during transit, optimizes space utilization, and supports timely order fulfillment in the supply chain process.

Skills Required for Pickers vs Packers

Pickers require strong attention to detail, spatial awareness, and familiarity with inventory management systems to accurately locate and retrieve items from warehouse shelves. Packers need skills in efficient packing techniques, knowledge of packaging materials, and the ability to ensure products are securely packed to prevent damage during transit. Both roles demand physical stamina and time management, but pickers emphasize accuracy in selection while packers focus on protection and presentation of goods.

Tools and Equipment Used in Picking and Packing

Pickers rely heavily on tools such as handheld barcode scanners, RF terminals, and automated picking systems like conveyor belts and pick-to-light technology to increase accuracy and speed in locating items within the warehouse. Packers use equipment like packing tables, tape dispensers, box cutters, and automated carton sealing machines to efficiently prepare products for shipment while ensuring protection and compliance with shipping standards. Both roles benefit from ergonomic tools, including adjustable workstations and safety gear, which enhance productivity and reduce workplace injuries during the picking and packing processes.

Efficiency and Productivity Comparisons

Pickers excel in quickly locating and retrieving items from inventory shelves, significantly reducing order preparation time and enhancing overall warehouse throughput. Packers specialize in efficiently assembling, packaging, and labeling products to ensure order accuracy and minimize shipping errors, directly impacting customer satisfaction and return rates. Optimizing the collaboration between pickers and packers leads to streamlined workflows, increased productivity, and maximized operational efficiency in warehousing environments.

Health and Safety Considerations

Pickers and packers face distinct health and safety challenges in warehousing environments. Pickers are more prone to musculoskeletal injuries due to repetitive bending, lifting, and walking, necessitating ergonomic tools and regular breaks to reduce strain. Packers require proper workstation design and safe handling protocols to prevent repetitive motion injuries and ensure chemical safety when packing various products.

Career Growth Opportunities

Pickers gain expertise in inventory management and order accuracy, providing a solid foundation for advancement into supervisory roles or warehouse operations management. Packers develop skills in packaging technology and quality control, which can lead to career growth in logistics coordination or quality assurance positions. Both roles offer pathways to specialized careers in supply chain management, emphasizing efficiency and operational excellence.

Typical Work Environments

Pickers and packers operate in fast-paced warehouse environments where accuracy and efficiency are critical. Pickers typically work on warehouse floors, navigating aisles to retrieve specific products based on order lists, often using handheld scanners or automated systems. Packers usually work at packing stations or conveyor belts, focusing on securely packaging items for shipment while ensuring order completeness and proper labeling.

Choosing Between a Picker and Packer Role

Choosing between a picker and packer role depends on specific warehouse operational needs and skill sets; pickers specialize in accurately selecting products from inventory shelves, optimizing order accuracy and retrieval speed. Packers focus on securely packaging items to minimize damage during shipping, ensuring correct labeling and efficient space utilization in boxes. Prioritizing picker roles enhances inventory management efficiency, while packer roles are critical for maintaining product integrity and customer satisfaction during delivery.

Picker vs Packer Infographic

jobdiv.com

jobdiv.com