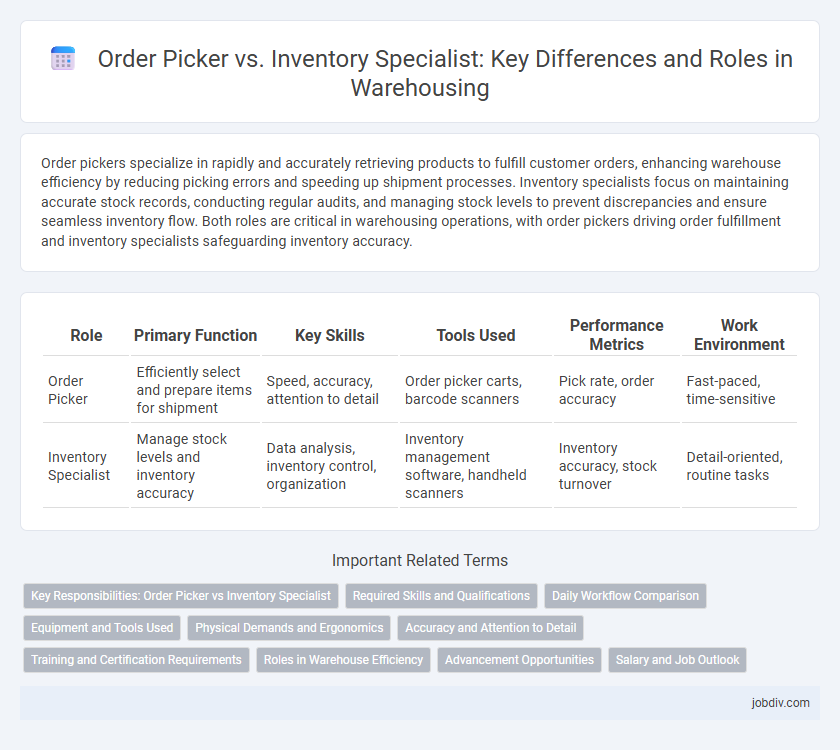

Order pickers specialize in rapidly and accurately retrieving products to fulfill customer orders, enhancing warehouse efficiency by reducing picking errors and speeding up shipment processes. Inventory specialists focus on maintaining accurate stock records, conducting regular audits, and managing stock levels to prevent discrepancies and ensure seamless inventory flow. Both roles are critical in warehousing operations, with order pickers driving order fulfillment and inventory specialists safeguarding inventory accuracy.

Table of Comparison

| Role | Primary Function | Key Skills | Tools Used | Performance Metrics | Work Environment |

|---|---|---|---|---|---|

| Order Picker | Efficiently select and prepare items for shipment | Speed, accuracy, attention to detail | Order picker carts, barcode scanners | Pick rate, order accuracy | Fast-paced, time-sensitive |

| Inventory Specialist | Manage stock levels and inventory accuracy | Data analysis, inventory control, organization | Inventory management software, handheld scanners | Inventory accuracy, stock turnover | Detail-oriented, routine tasks |

Key Responsibilities: Order Picker vs Inventory Specialist

Order Pickers are responsible for accurately retrieving products from warehouse shelves to fulfill customer orders, ensuring timely and precise order completion. Inventory Specialists manage stock levels by monitoring inventory accuracy, conducting cycle counts, and coordinating stock replenishment to prevent shortages or overstock. Both roles are crucial for efficient warehouse operations but focus respectively on order fulfillment and inventory control.

Required Skills and Qualifications

Order Pickers require strong physical stamina, attention to detail, and proficiency in operating warehouse equipment such as forklifts and pallet jacks. Inventory Specialists need advanced organizational skills, expertise in inventory management software, and the ability to analyze stock levels for accurate reporting and restocking. Both roles demand basic math skills, effective communication, and a solid understanding of safety protocols within warehouse environments.

Daily Workflow Comparison

Order pickers primarily focus on retrieving products efficiently to fulfill customer orders, relying on speed and accuracy during high-volume picking cycles. Inventory specialists concentrate on organizing, tracking, and maintaining stock levels through regular cycle counts and data entry, ensuring inventory accuracy and availability. Both roles employ warehouse management systems but differ in their daily priorities, with order pickers emphasizing order completion and inventory specialists ensuring stock integrity.

Equipment and Tools Used

Order pickers primarily utilize manual pallet jacks, electric order pickers, and handheld barcode scanners to efficiently locate and retrieve products in warehouse aisles. Inventory specialists rely on advanced inventory management software, RFID scanners, and mobile computing devices to maintain precise stock levels and conduct accurate cycle counts. Both roles integrate warehouse management systems (WMS) but differ in hands-on equipment, with order pickers favoring physical retrieval tools and inventory specialists emphasizing digital tracking technologies.

Physical Demands and Ergonomics

Order Pickers often face intense physical demands, including repetitive lifting, bending, and prolonged standing, which can lead to musculoskeletal strain without proper ergonomic support. Inventory Specialists typically engage in less physically strenuous tasks such as data management and stock monitoring, but may still require occasional moderate lifting and walking. Ergonomic interventions like adjustable workstations, proper lifting techniques, and supportive footwear are crucial to reducing injury risks for both roles in warehousing environments.

Accuracy and Attention to Detail

Order pickers excel in accuracy by rapidly selecting items based on precise order specifications, minimizing errors during the fulfillment process. Inventory specialists ensure meticulous attention to detail through regular audits and precise stock management, maintaining optimal inventory accuracy. Both roles are critical for reducing discrepancies and supporting efficient warehouse operations.

Training and Certification Requirements

Order Pickers typically require training in safe equipment operation, including forklifts and pallet jacks, with certifications such as OSHA forklift certification often mandated. Inventory Specialists need comprehensive training in inventory management systems and data accuracy, with certifications like Certified Inventory Specialist (CIS) enhancing their qualifications. Both roles benefit from ongoing safety training and familiarity with warehouse management software to ensure efficient and compliant operations.

Roles in Warehouse Efficiency

Order Pickers streamline warehouse efficiency by rapidly retrieving and preparing products for shipment, reducing order cycle times and improving customer satisfaction. Inventory Specialists maintain accurate stock levels through regular audits, data reconciliation, and inventory forecasting, minimizing stockouts and overstock situations. Coordinated roles of both professionals enhance operational workflow, balancing speed with precision in warehouse management.

Advancement Opportunities

Order pickers can advance to supervisory roles or specialize in equipment operation such as forklift driving, often gaining certifications to increase their career mobility. Inventory specialists may progress into inventory management, data analysis, or supply chain coordination positions, leveraging their detailed knowledge of stock control and software systems. Both roles offer pathways to broader warehouse management positions through experience and ongoing training.

Salary and Job Outlook

Order pickers typically earn an average annual salary ranging from $28,000 to $38,000, with job growth projected at 6% over the next decade, reflecting steady demand in warehousing operations. Inventory specialists command higher salaries, averaging between $40,000 and $55,000 annually, driven by responsibilities involving stock accuracy and inventory management, with job outlook growth around 7%. Both roles are essential in supply chain management, but inventory specialists benefit from stronger salary prospects and marginally better employment growth rates.

Order Picker vs Inventory Specialist Infographic

jobdiv.com

jobdiv.com